Vehicle-mounted hydrogen storage cylinder service monitoring device and method based on optical fiber sensing

An optical fiber sensing and monitoring device technology, applied in measurement devices, collaborative devices, instruments, etc., can solve the problems of insufficient electrical signal stability, backwardness, data error reporting, etc., to meet development needs, ensure safety and reliability, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

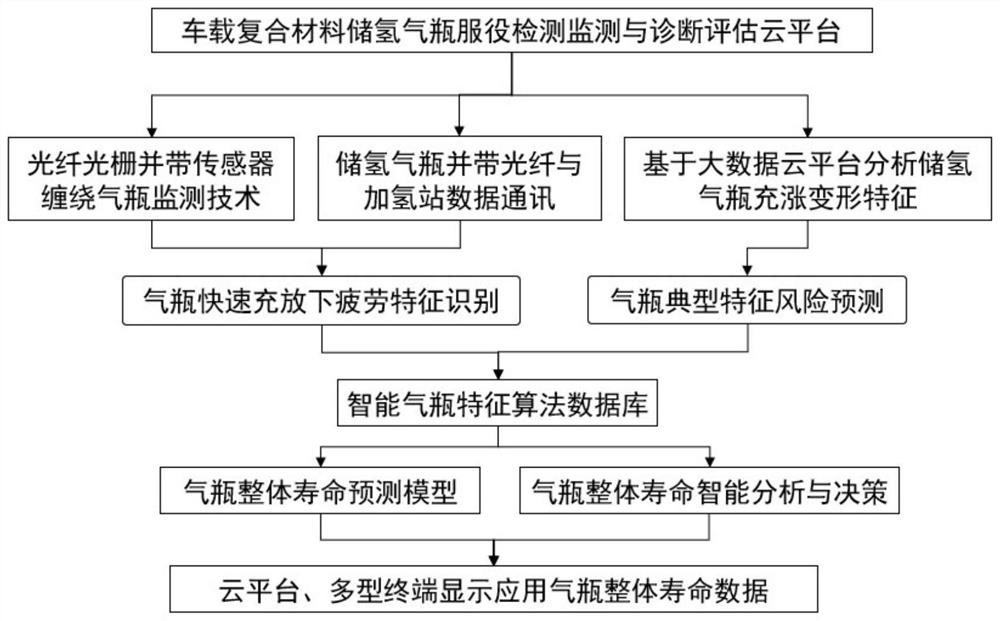

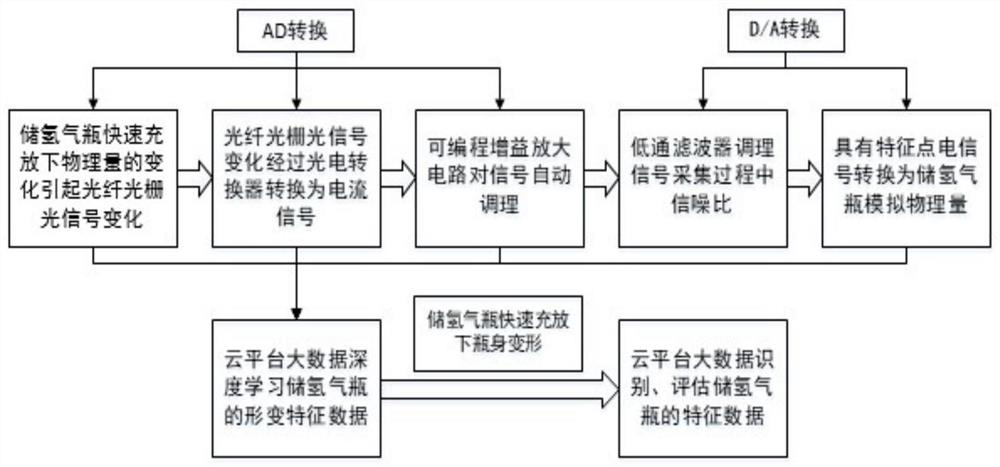

[0046] see figure 1 , The embodiment of the present invention includes fiber grating and sensor winding gas cylinder monitoring technology, hydrogen storage gas cylinder with optical fiber and hydrogen refueling station data communication technology, and a method for analyzing inflation and deformation characteristics of hydrogen storage gas cylinders based on a big data cloud platform.

[0047] Fiber Bragg grating and sensor winding gas cylinder monitoring technology

[0048] Although the common bare fiber grating has excellent strain sensing performance, the working environment in the actual engineering project of the hydrogen storage cylinder is complex and changeable, and it is easy to be broken when exposed, resulting in interruption of the monitoring signal, and it is extremely inconvenient to paste, which greatly increases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com