Assembly line rebalance optimization method considering energy consumption

An optimization method, assembly line technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., to achieve the effect of improving production efficiency and reducing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

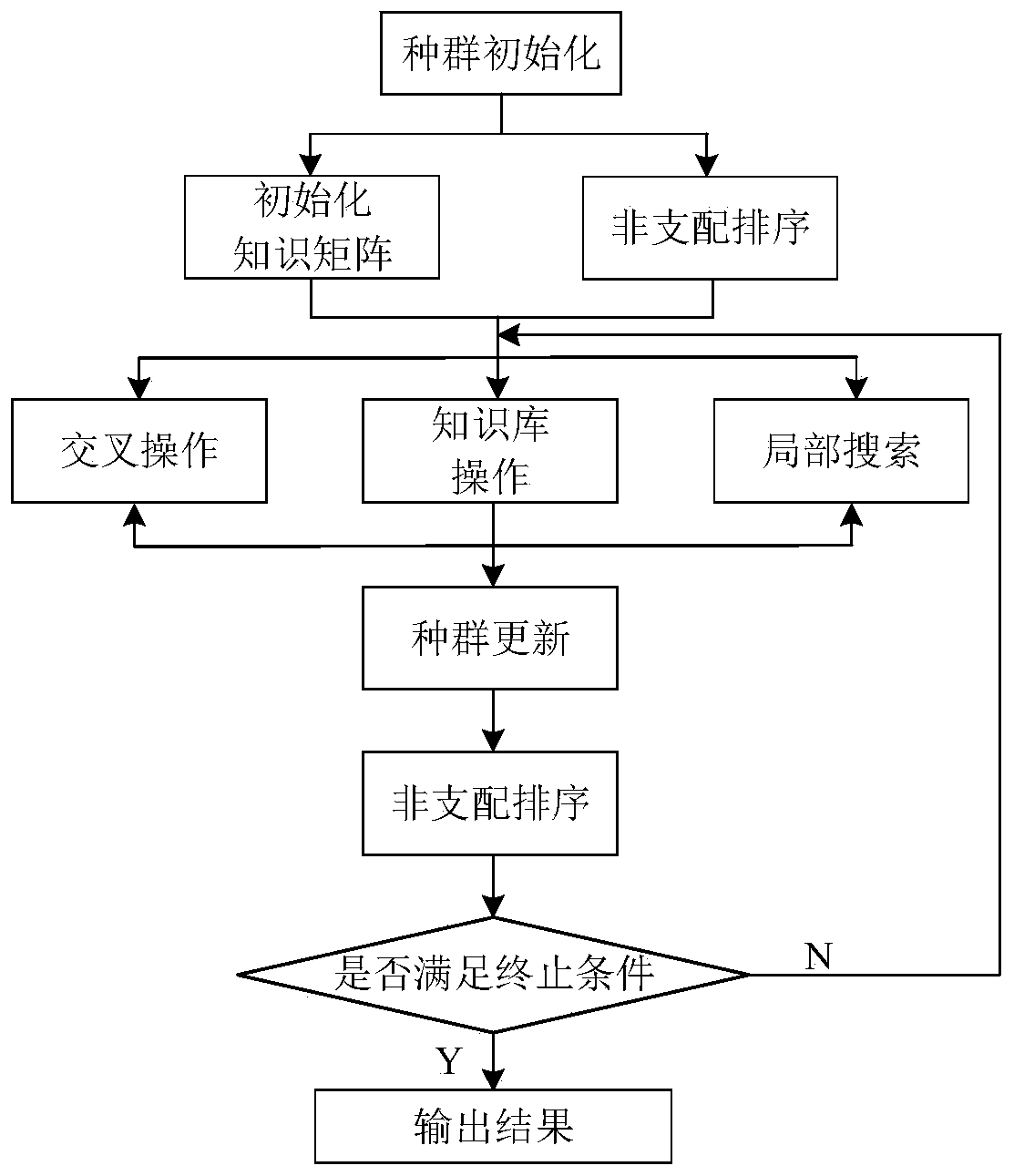

[0067] This application proposes an assembly line rebalancing optimization method considering energy consumption, including the following steps:

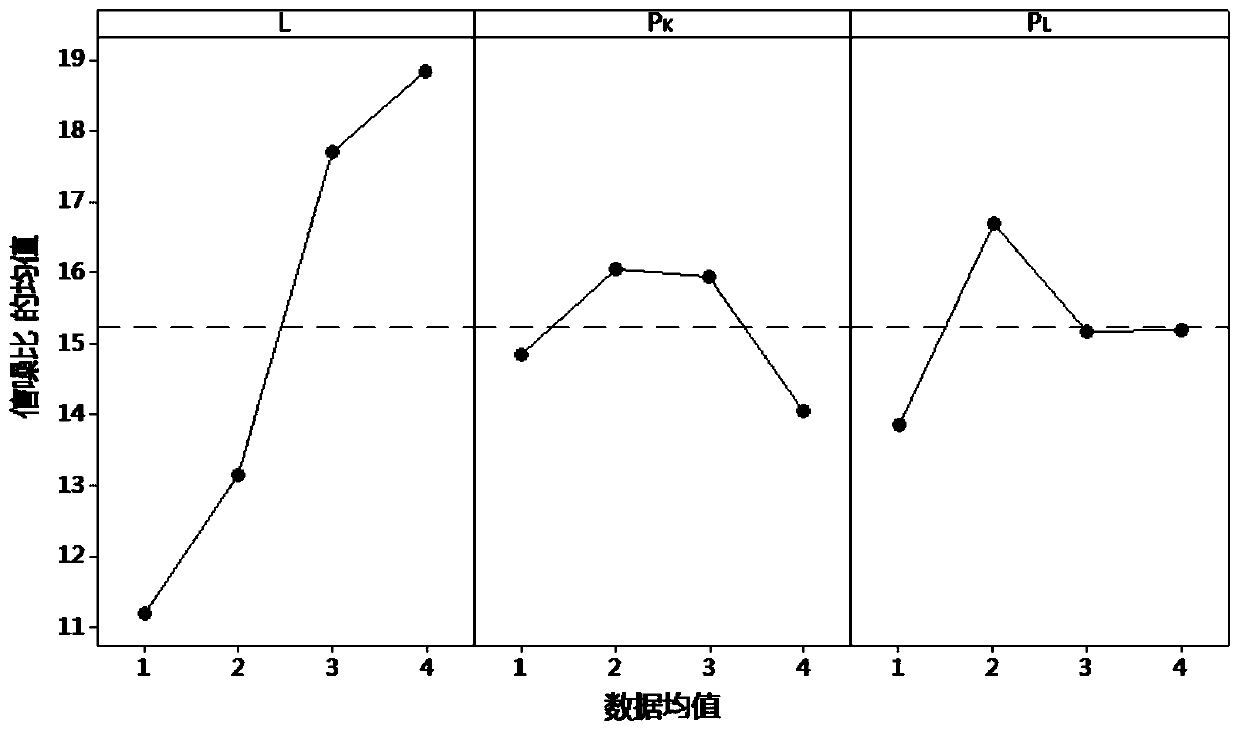

[0068] S1. On the premise of fully understanding the mechanism of assembly line rebalancing energy consumption, a multi-objective optimization model for assembly line rebalancing is established with the goal of minimizing smoothness coefficient, energy consumption and transfer tasks, as follows:

[0069] The objective function of the multi-objective optimization model includes: smoothing coefficient function, energy consumption function and transfer task number function; the smoothing coefficient function is:

[0070]

[0071] Among them, n represents the total number of stations on the assembly line; m represents the total number of assembly tasks; C T Indicates the maximum completion time; x ij Indicates the task assignment law in the new balance plan, if task i is assigned to station j in the new balance plan, then x ij = 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com