Small-caliber conical plate rolling machine and use method thereof

A plate rolling machine and small-diameter technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low precision, plate rolling machines can only be rolled into cylinders, and tools cannot meet the requirements, etc. The effect of uniform force and prevention of offset position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

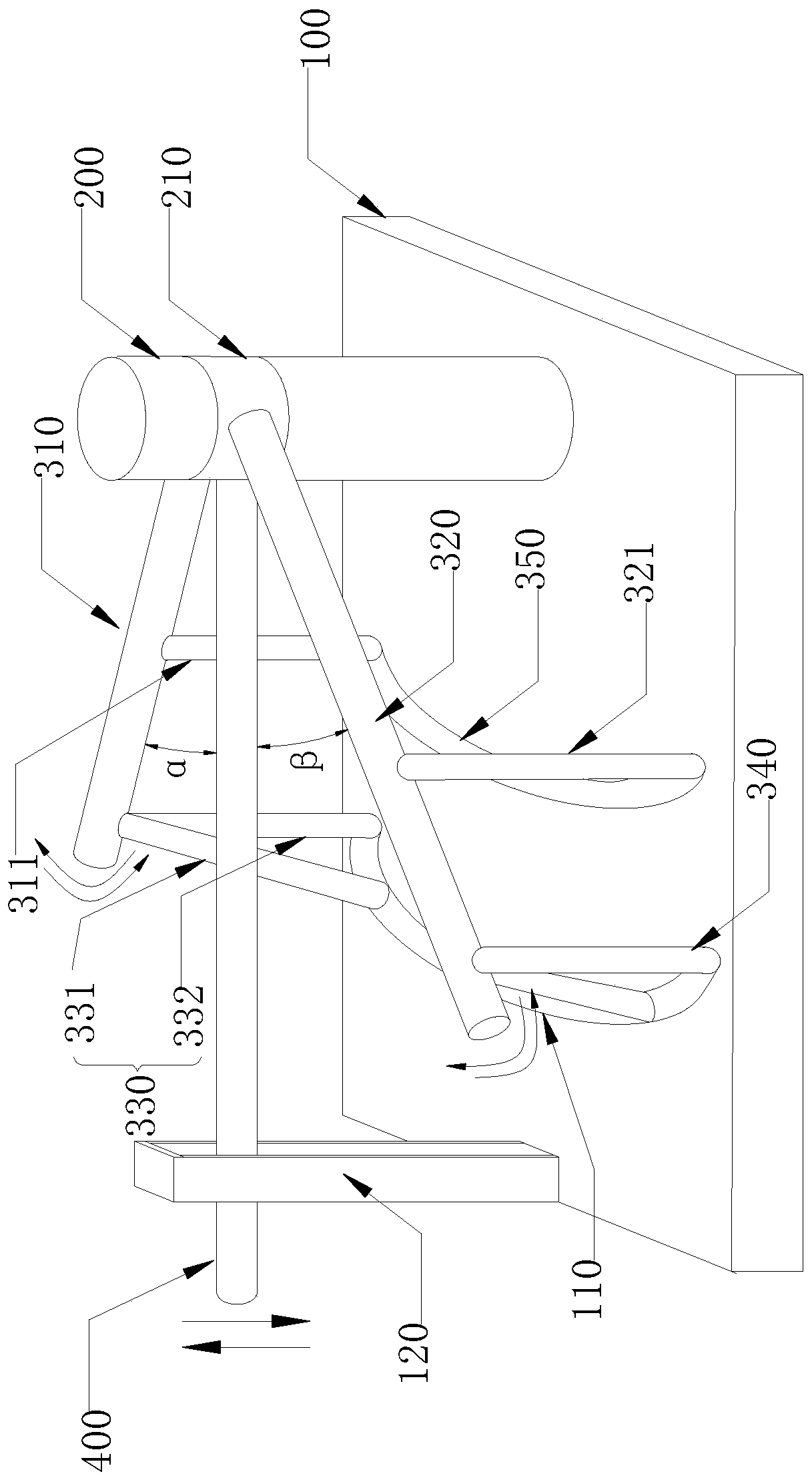

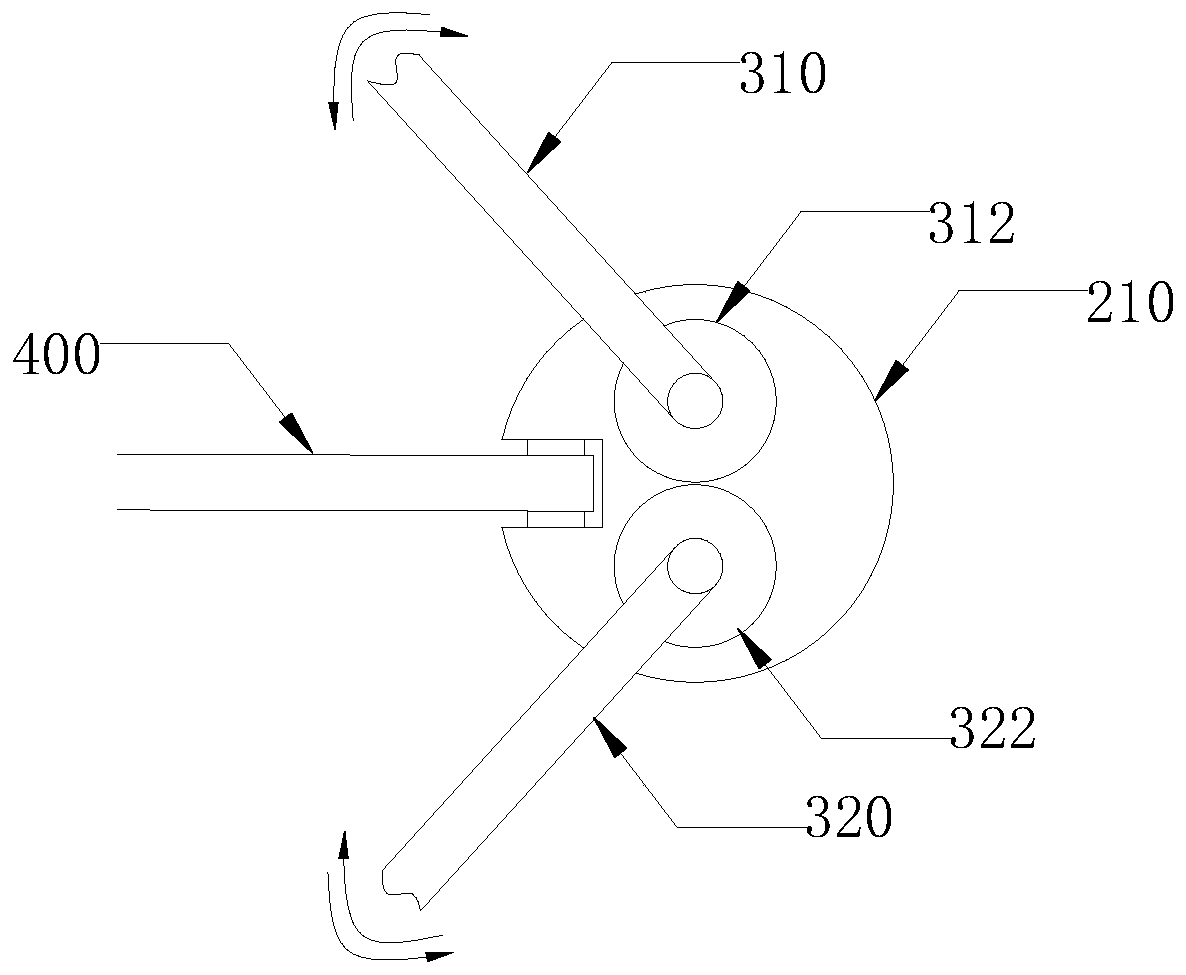

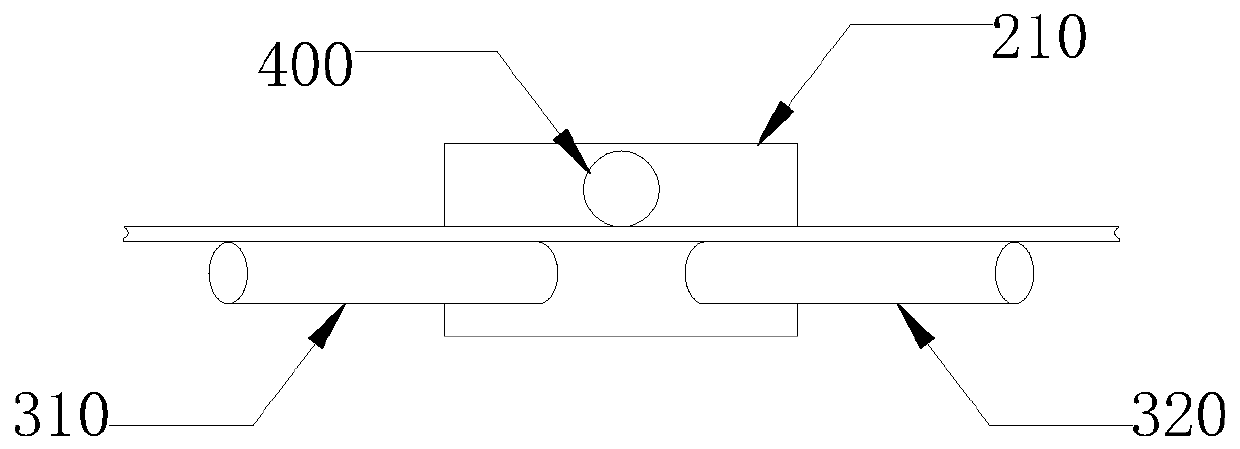

[0038] Such as figure 1 , image 3 , Figure 4 As shown, a small-diameter conical plate bending machine described in this embodiment includes: a base 100, a support column 200, a first adjustment roller 310, a second adjustment roller 320, and a pressure roller 400; The support column 200 is arranged on the base 100, the support column 200 is provided with a connection part 210, the first adjustment roller 310, the second adjustment roller 320 are connected to the connection part 210 in a horizontal direction, and the pressure roller 400 is connected to the connection part 210. The connection part 210 is connected in the vertical direction; the first adjustment roller 310, the second adjustment roller 320 and the pressure roller 400 are all connected to the connection part 210, and the first adjustment roller 310, the second adjustment roller 320 and the pressure roller 400 are determined The position and the angular relationship of the position and the angle relationship ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com