Set-off prevention device of printing machine

An anti-smearing and printing machine technology, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of surface characteristic changes, poor ink absorption, ink accumulation, etc., and achieve strong surface stability and low implementation cost Low, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

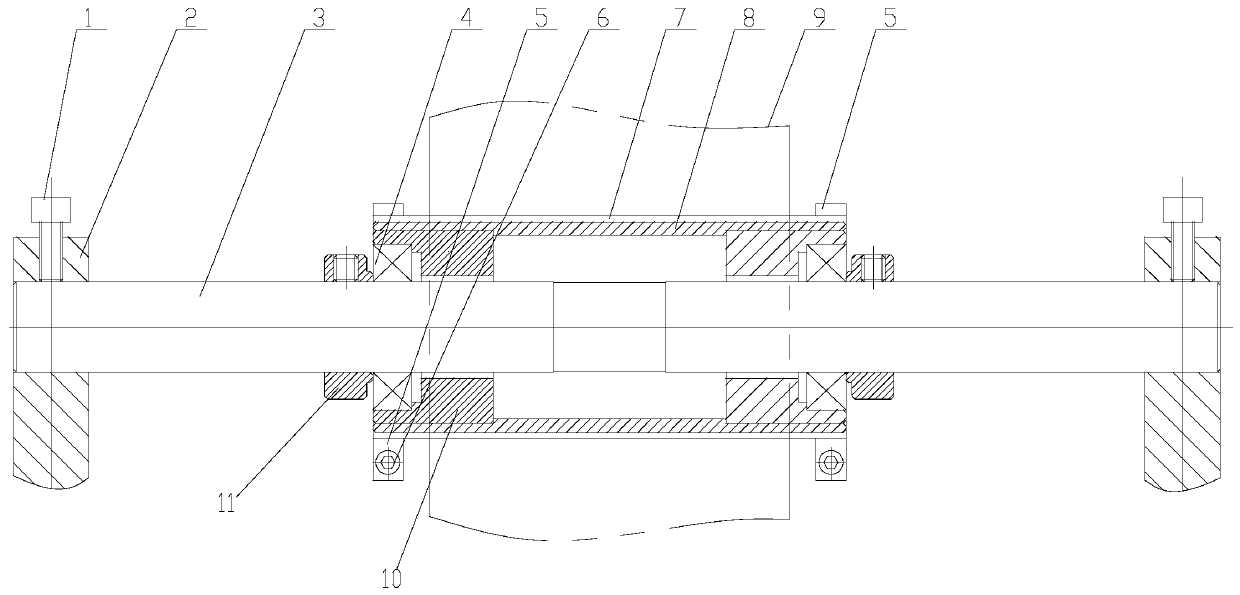

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] figure 1 Among them, it includes the main first screw 1, the bearing 2, the shaft 3, the bearing 4, the clamping seat 5, the second screw 6, the rasp file 7, the paper guide roller 8 and so on.

[0013] like figure 1 As shown, the present invention is a printing machine anti-smudge device, including a shaft 3, a paper guide roller 8 is supported on the shaft 3 through a bearing 4, and the axial inner end of the bearing 4 passes through the inner boss of the paper guide roller 8 Shaft shoulder limit, the axial outer end of the bearing 4 is axially positioned by the positioning ferrule 11, the surface of the paper guide roller 8 is evenly wound around the file 7, and the file 7 is along the surface axis of the paper guide roller 8 Extending from one end to the other axial end, the two axial ends of the shaft 3 are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com