Foam extinguishing agent based on fluorocarbon-organosilicon surfactant compound system

A technology of surfactant and foam fire extinguishing agent, used in fire protection equipment and other directions, can solve the problems of fire-extinguishing foam's heat-resistant and liquid-resistant stability to be improved, poor fire-extinguishing effect, high fire danger, etc., to achieve fire-fighting and anti-burning The effect of excellent performance, non-degradable and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

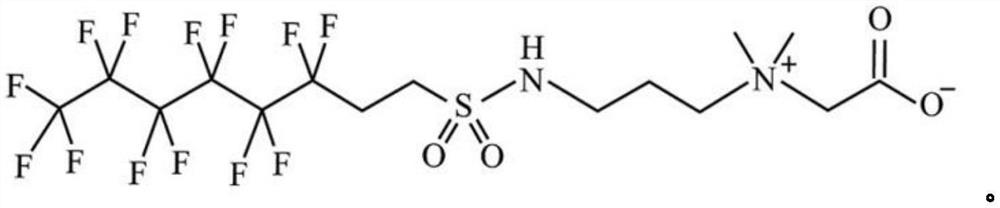

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of aqueous film-forming foam extinguishing agent concentrate (100kg, 3% type)

[0022] Take by weighing 2kg of perfluorooctane sulfonamide alkyl betaine, respectively. 20kg of 501W type organosilicon surfactant is added to the reactor, then 45kg of industrial soft water is added, and stirring is started, and the stirring speed is 120 rev / min; 2kg, ammonium polyphosphate 3kg, sodium diacetate 1kg, after stirring and mixing, adjust the pH value of the solution with a pH regulator, and stir to obtain the product.

Embodiment 2

[0023] Example 2: Preparation of aqueous film-forming foam extinguishing agent concentrate (100kg, 3% type)

[0024] Take by weighing 2kg of perfluorooctane sulfonamide alkyl betaine, respectively. 30kg of 501W type organosilicon surfactant was added to the reaction kettle, 35kg of industrial soft water was added, stirring was started, and the stirring speed was 120 rev / min; Base cellulose 2kg, sodium alginate 2kg, ammonium polyphosphate 3kg, potassium sorbate 1kg, after stirring and mixing, adjust the pH value of the solution with a pH regulator, and stir to obtain the product.

Embodiment 3

[0025] Example 3: Preparation of aqueous film-forming foam extinguishing agent concentrate (100kg, 6% type)

[0026] Take by weighing 2kg of perfluorooctane sulfonamide alkyl betaine, respectively. 20kg of 501W type organosilicon surfactant is added to the reaction kettle, 40kg of industrial soft water is added, and stirring is started, and the stirring speed is 120 rev / min; , ammonium polyphosphate 3kg, sodium diacetate 1kg. After stirring and mixing, the pH value of the solution is adjusted with a pH regulator, and the product is obtained by stirring evenly.

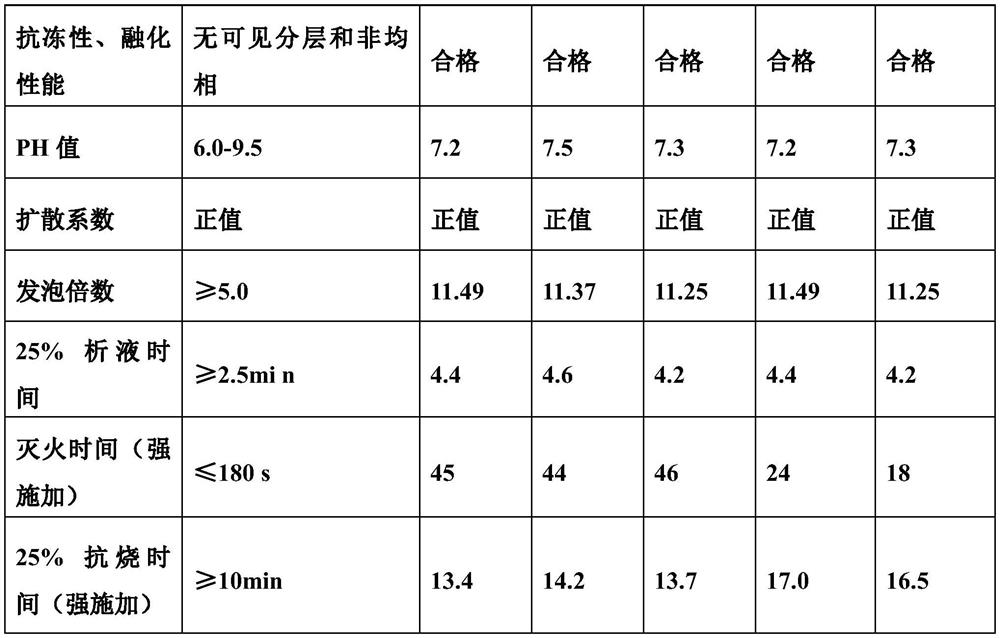

[0027] The above-mentioned examples 1 and 2 were mixed with water in a mass ratio of 3:97, and the above-mentioned example 3 was mixed with water in a mass ratio of 6:94 to prepare a solution for extinguishing fire. The product of the present invention is self-tested according to the national standard "GB15308-2006" of "Foam Fire Extinguishing Agent". The physical and chemical properties and fire extinguishing perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com