Material discharging device

A technology of discharging and piping, applied in the field of auxiliary equipment of mining equipment, can solve the problems of high impact force of conveyor belt, easy damage to conveyor belt, wear of inner wall of funnel, etc., to reduce impact force, prolong service life and reduce maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

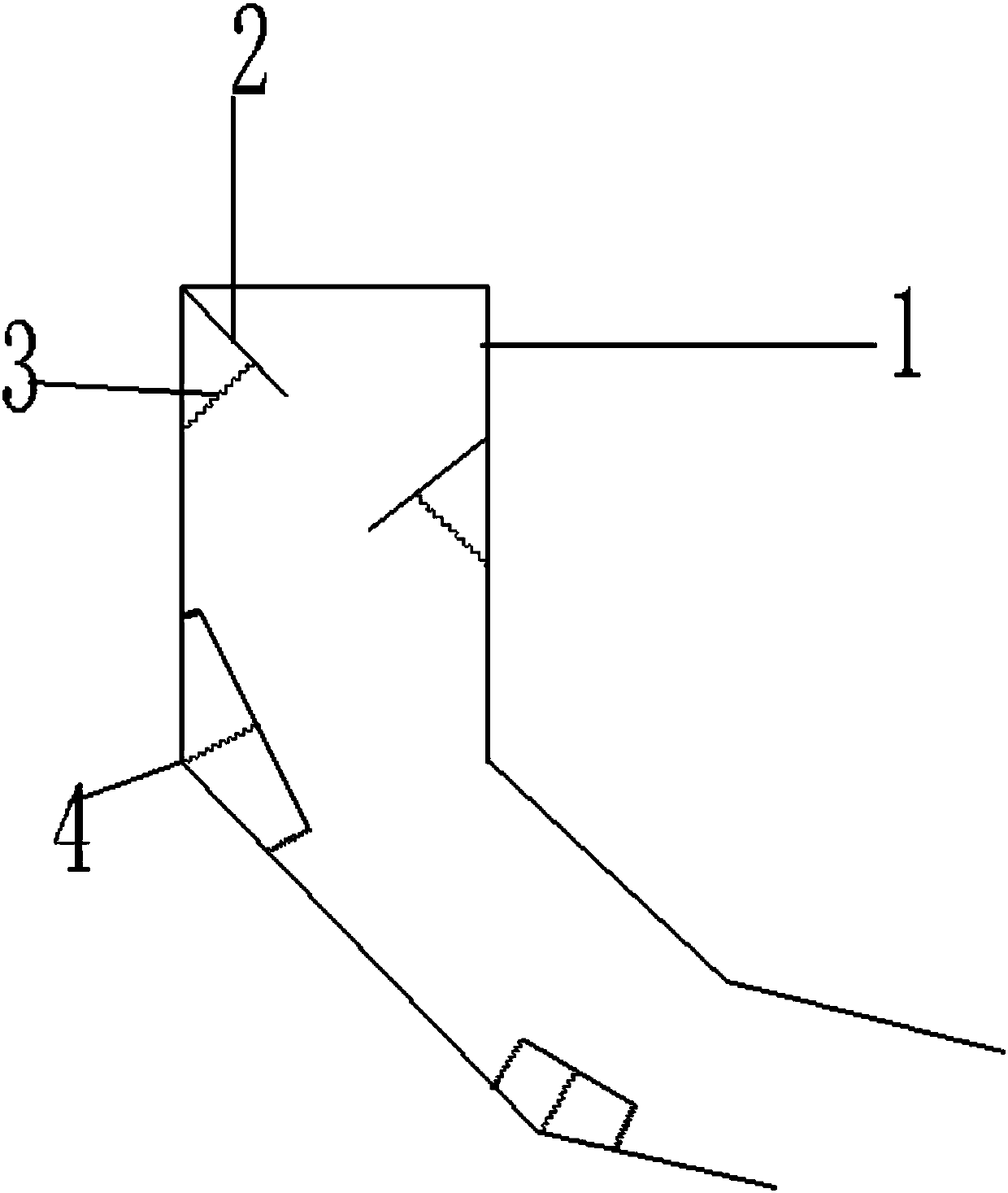

[0015] With reference to the accompanying drawings in the specification, the present invention provides a discharge device, wherein several discharge pipes 1 are sequentially connected, and each discharge pipe 1 is provided with a plurality of baffles 2, and the upper end of each baffle 2 is connected to the wall of the pipe. Rotary shaft connection, the lower end of the baffle plate 2 is connected with the pipe wall using a spring 3, and the two adjacent baffle plates 2 are alternately arranged in the pipe wall; every two adjacent pipe inner wall connections are provided with a buffer plate 4, so The two ends of the buffer plate 4 are respectively connected to the inner walls of the two pipes by springs 3 .

[0016] Preferably, the angle between every two adjacent discharge pipes 1 is an obtuse angle.

[0017] Preferably, the discharge pipeline 1 has at least two sections.

[0018] The present invention reduces the falling speed of the ore by setting the inclined discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com