Systems and methods for operating fuel system responsive to inferred fuel temperature

A fuel temperature and fuel technology, applied in the direction of charging system, fuel injection device, fuel injection control, etc., can solve the problems of inaccuracy, inaccuracy, sacrifice of fuel economy, etc., and achieve the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

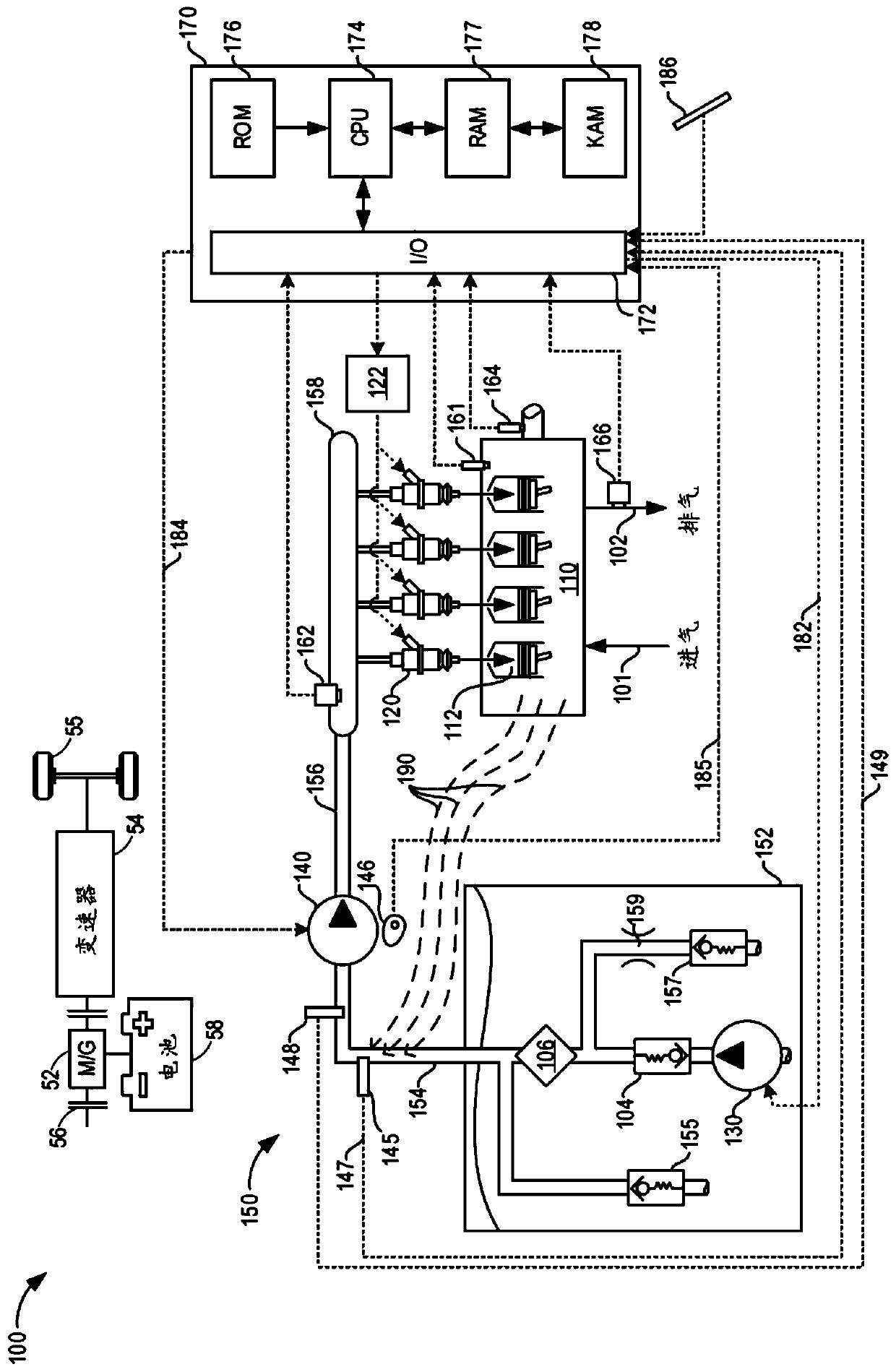

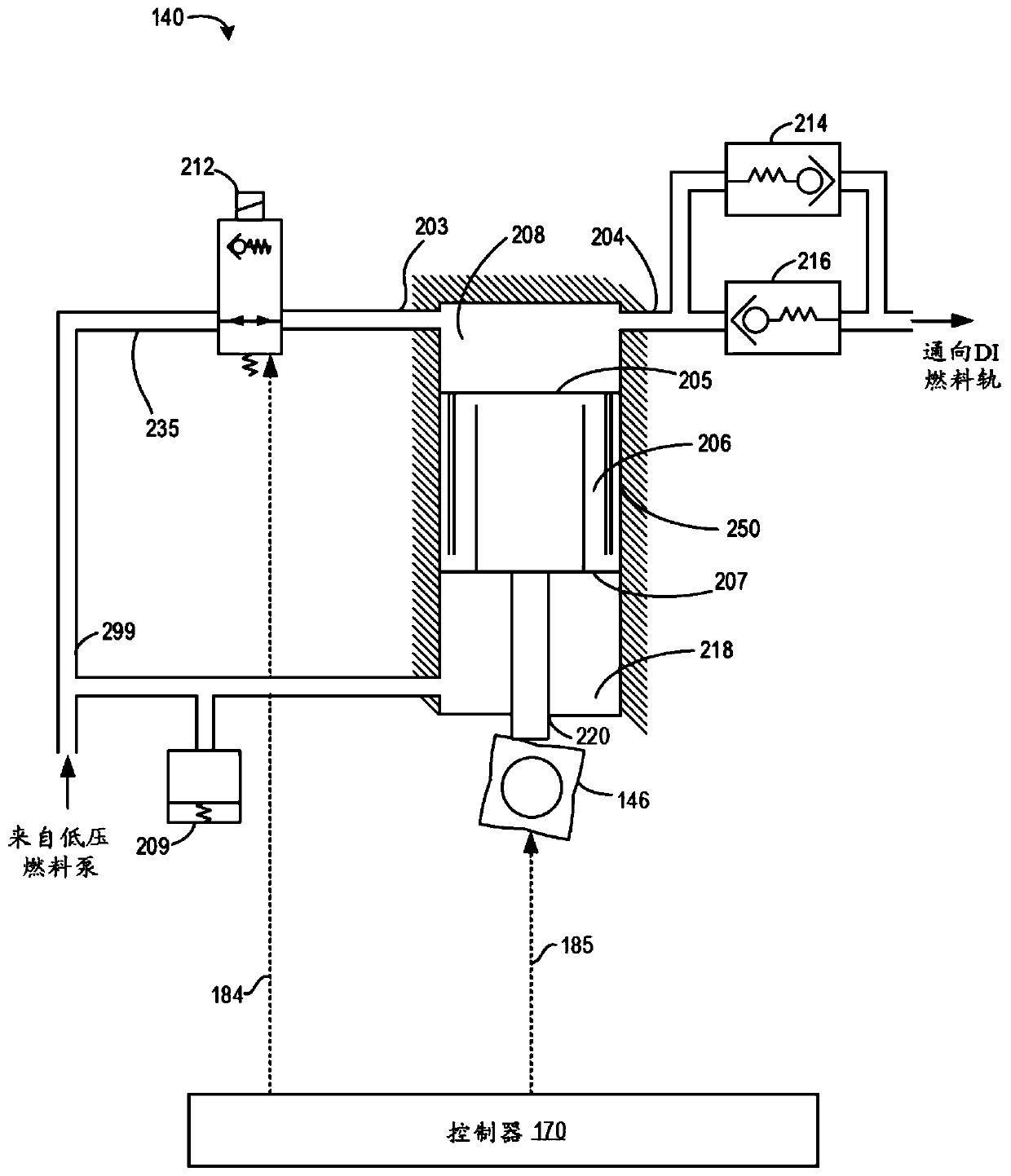

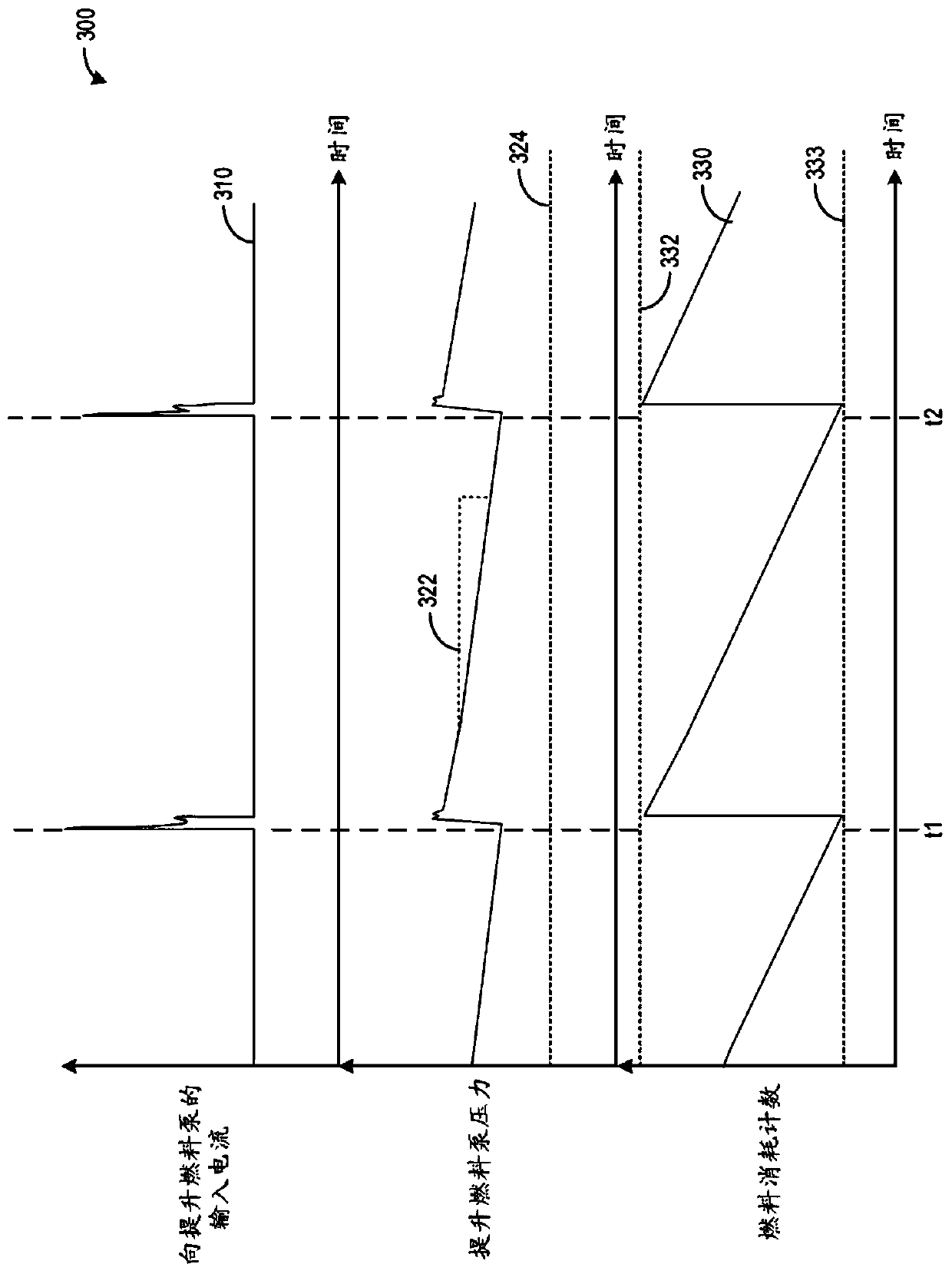

[0016] The following detailed description provides information regarding systems and methods for inferring fuel system fuel temperature from a rate of change of fuel pressure and operation of the fuel system in response thereto. exist figure 1 A simplified schematic of an example direct injection fuel system and engine is shown in , while figure 2 show figure 1 Detailed drawing of a direct injection fuel pump and associated components. image 3 A diagram is shown between two different control schemes for input current to the lift fuel pump and the operation of the fuel lift pump at Figure 4 exemplifies. Figure 5 to Figure 6 Fuel pressure is shown for various engine and fuel system conditions, including how fuel pressure stiffness may inform fuel system check valve diagnostics. exist Figure 7 and Figure 9 Inferring fuel temperature based on fuel pressure rate of change and operating in response to it is shown in figure 1 approach to the fuel system. Figure 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com