A grid sealing structure with self-adjusting grid stack gap

A sealing structure and self-adjusting technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of increased leakage, narrow operating temperature range, and inability to self-adjust when the gap increases, so as to achieve the effect of small leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

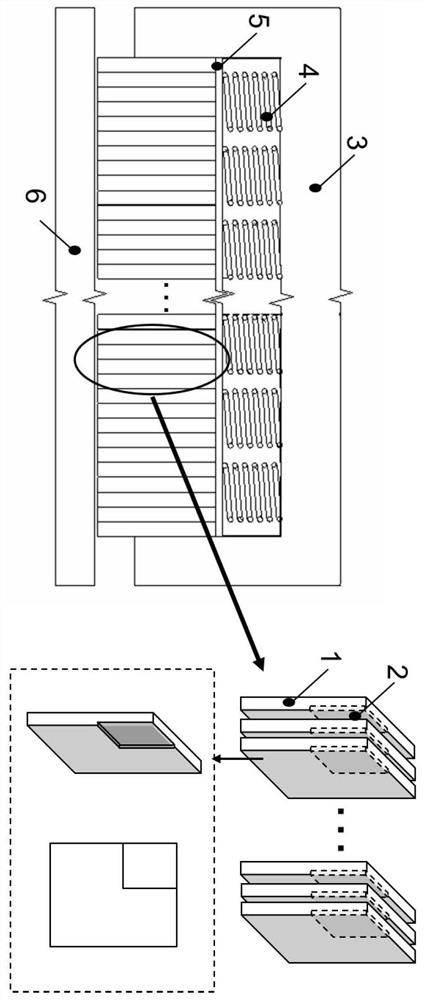

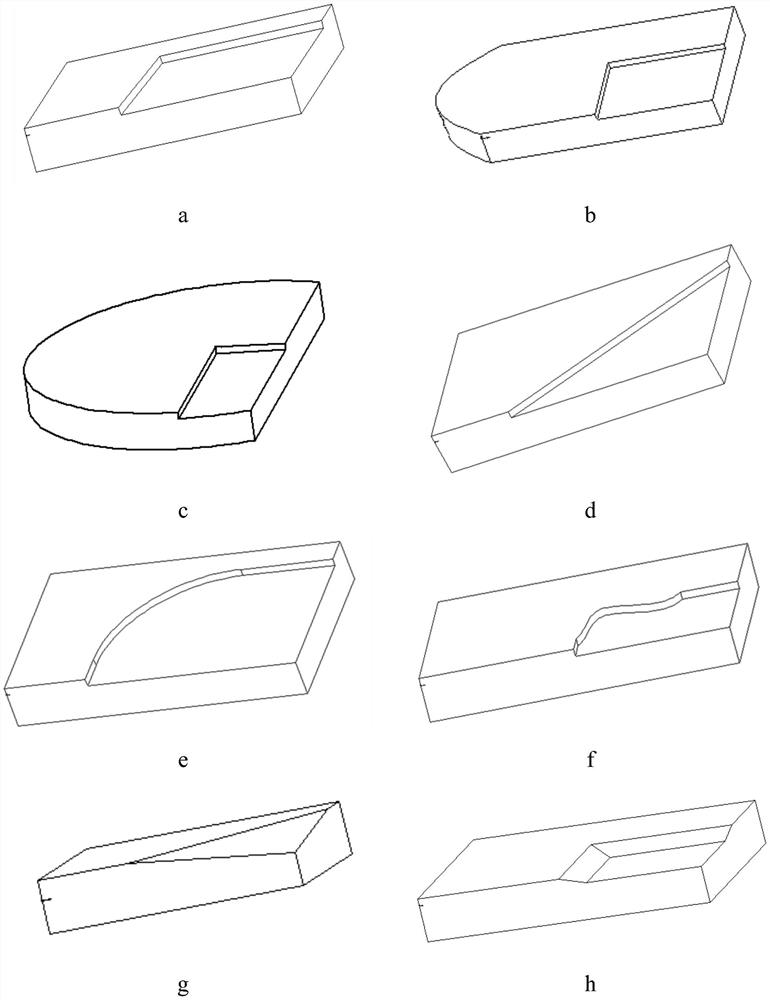

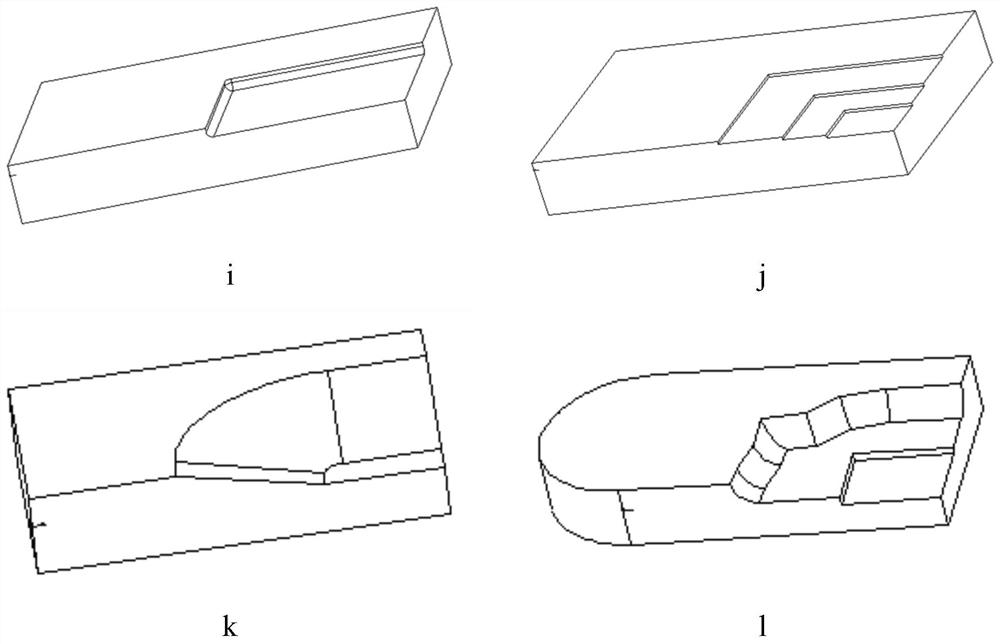

[0030] refer to figure 1 , image 3 , assuming that the figure 2 As shown in a, if one corner of the grid plate has a rectangular groove shape, the projected shape of the gas film produced after stacking is rectangular, and the high-voltage side has a projection with a rectangular projection surface, where the thickness of the raised part is the thickness of the step 2 Δh , which is constant, and the thickness without protrusions is the grid spacing h0, which is variable. When the area of the grid is 12×20mm, and the area of the step 2 is 6×10mm, the sealed high-pressure side is the adjacent two boundaries (Set left and upper), the pressure is 0.8MPa, the low-pressure side is located at the right boundary, and the length of 3.5mm connected to the lower boundary, the pressure is 0.1MPa, at the right boundary and the lower boundary, the square of the pressure is linearly related to the position, Then the relationship between the air film force and the grid gap h0 is shown...

Embodiment 2

[0032] refer to figure 1 , Figure 4 , Figure 4 Shown is the geometric model of the RBCC binary inlet, the fixed wall 10 and the movable plate 8 are connected by a hinge 7, and the space enclosed forms a variable flow channel 9. The grid plate structure of the present invention is installed on the movable flat plate 8 and contacts with the side wall to form a sealing structure. The rotation angle of the hinge 7 is small and the speed is slow. Therefore, the sealing structure can be regarded as a linear sealing structure moving in parallel. The leakage of the grid sealing structure is proportional to the cube of the gap, that is, Therefore, the leakage rate is particularly sensitive to clearance changes. Take the temperature change as an example: the material of the grid plate is generally a high temperature resistant composite ceramic material, and the material of the wall surface of the flow channel and the grid plate installation groove 3 is generally a high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com