Logistics object management system and logistics object management method

An object management and logistics technology, applied in the field of logistics, can solve problems such as inability to make, untimely operation, and stoppage of conveying lines, and achieve the effects of preventing overweight, reducing density, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0033] Such as figure 1 As shown, a logistics object transportation path may include, for example, a transportation line 1, a transportation line 2, a transportation line 3, and a transportation line 4, wherein the intersection area A1 of the transportation lines 3 and 4 is prone to blockage. The logistics object out of the warehouse enters the conveyor line 1 from the left side of the conveyor line 1, and the source of another logistics object—for example, the logistics object unloaded by the truck enters the conveyor line 4 from the entrance of the conveyor line 4, and the two logistics objects are converging Then enter the main conveying line 5, and finally enter the distribution area A2 for operation.

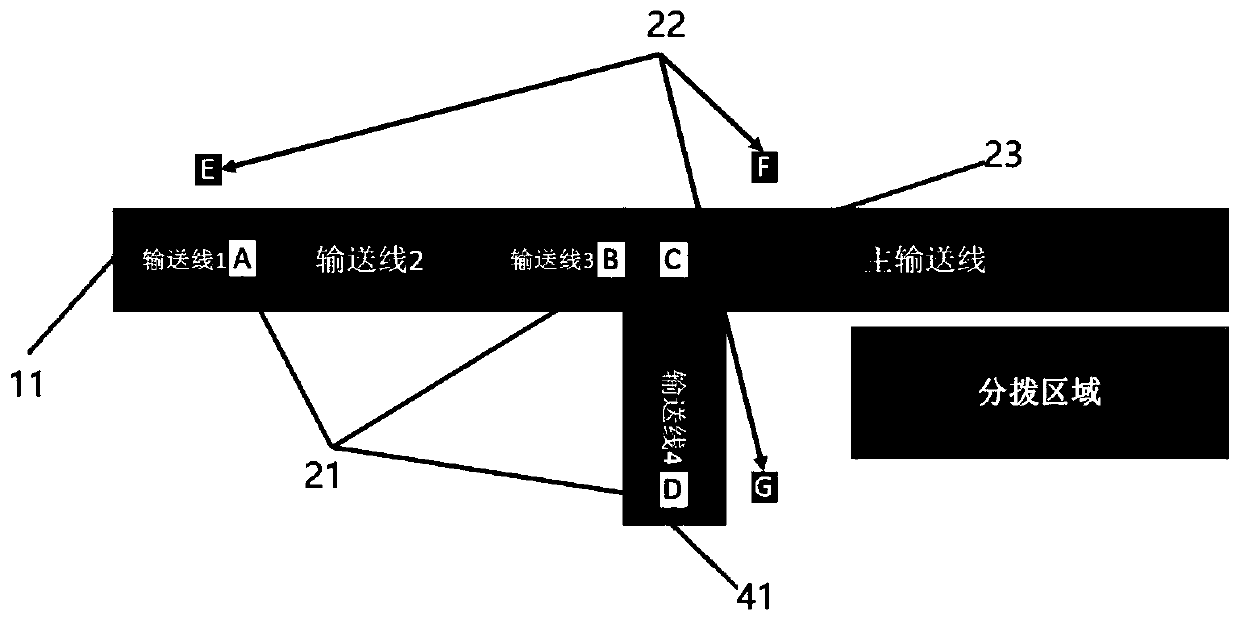

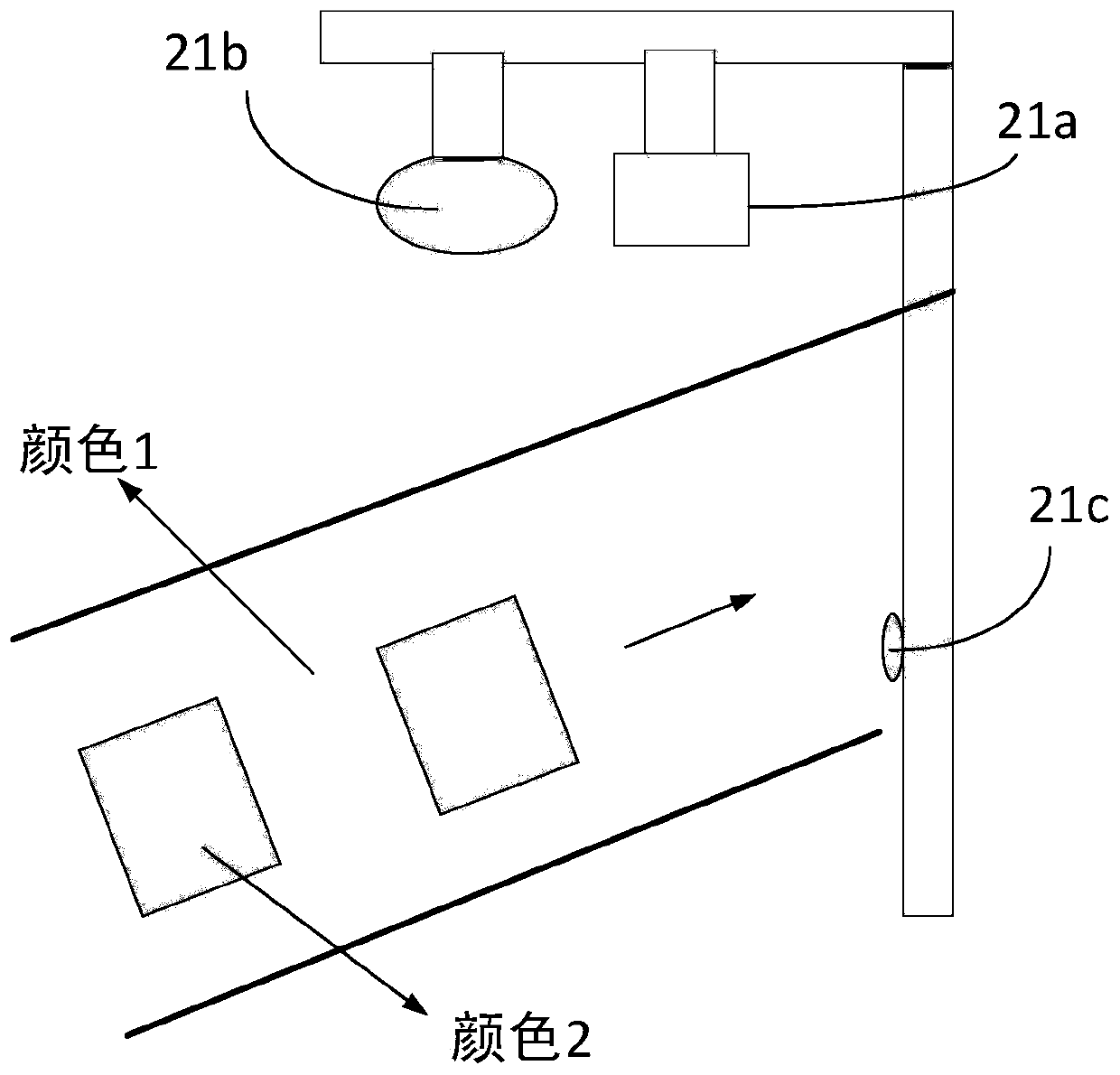

[0034] The first embodiment of the present invention proposes a logistics object management system. Such as figure 2 As shown, the logistics object management system proposed by the embodiment of the present invention is set on the logistics object delivery path. The lo...

no. 2 example

[0072] The second embodiment of the present invention proposes a logistics object management method, such as Figure 6 Shown is a flowchart of a logistics object management method according to an embodiment of the present invention. The method may include the following steps, for example:

[0073] S101, using the logistics object state detection device to respectively detect the state of the logistics object on each of the multiple logistics object conveying lines;

[0074] In this step, the execution subject, such as the processing device of the aforementioned logistics object management system, can obtain the status of the logistics object on the conveying line. In one embodiment, as figure 2 As shown, a logistics object state detection device 21 is arranged on the conveying line 1 , the conveying line 3 and the conveying line 4 . These logistics object state detection devices 21 can transmit the detected quantity of logistics objects to the processing device, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com