Four limb fracture annular banding and fixing assisting machine

An auxiliary device and cerclage technology, applied in the direction of fixators, internal fixators, internal bone synthesis, etc., can solve the problems of inability to disassemble, local cerclage angle cannot be adjusted, single application site, etc., and achieve the effect of avoiding violent injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

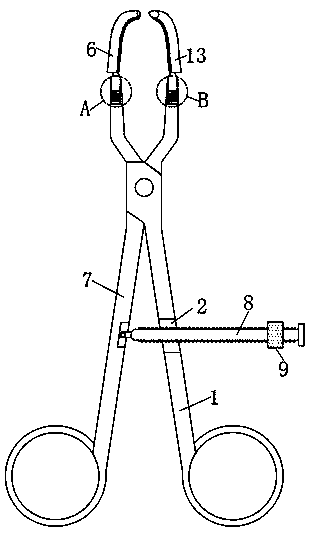

[0023] Such as Figure 1-4 , put the first handle 1 and the second handle 7 deep into the incision, and open the front ends of the first handle 1 and the second handle 7, so that the first embracing tube 6 and the second embracing tube 13 surround the fracture end, and then , twist the limit block 9, and move along the limit rod 8, so as to limit the opening angle of the tail ends of the first handle 1 and the second handle 7, and then pass the cable through the first encircling tube 6 and the The second embracing tube 13 can be cerclaged. Finally, the stop block 9 is twisted to loosen the first handle 1 and the second handle 7, and the first embracing tube 6 and the second embracing tube 13 are taken out.

Embodiment 2

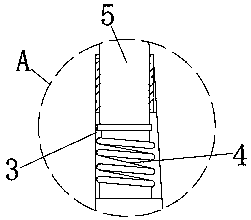

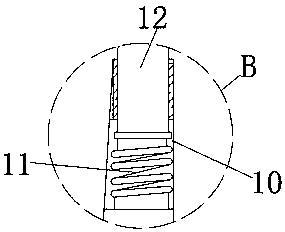

[0025] Such as Figure 1-5 , the first embracing tube 6 and the second embracing tube 13 are both arranged in an arc structure, and the front ends of the first embracing tube 6 and the second embracing tube 13 are both set in a pointed structure, according to the size of the incision and the fracture location, select a suitable arc and the first embracing pipe 6 and the second embracing pipe 13 of pipe diameter, and by the first connecting rod 5 and the second connecting rod 12, the first embracing pipe 6 and the second embracing pipe 13 are installed on the first handle 1 and the second embracing pipe 13 respectively. The upper end of the second handle 7 can be implemented by repeating Example 1 subsequently.

[0026] Working principle: When in use, according to the size of the incision and the location of the fracture, select the first embracing tube 6 and the second embracing tube 13 with appropriate curvature and tube diameter, and connect the first embracing tube 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com