A multi-layer superimposed high-strength ladle wood production equipment

A production equipment and high-strength steel technology, applied in the field of construction factories, can solve the problems of low automation, poor economic benefits, and low production efficiency, and achieve the effects of high kinetic energy utilization, high automation, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

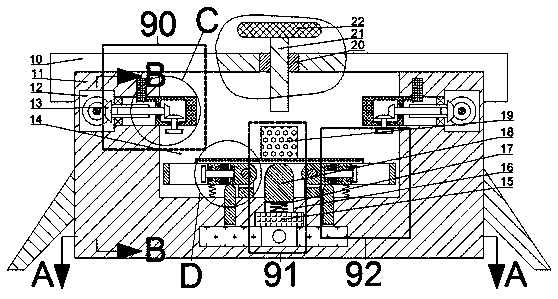

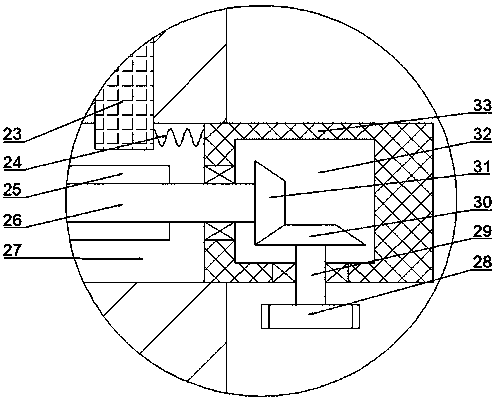

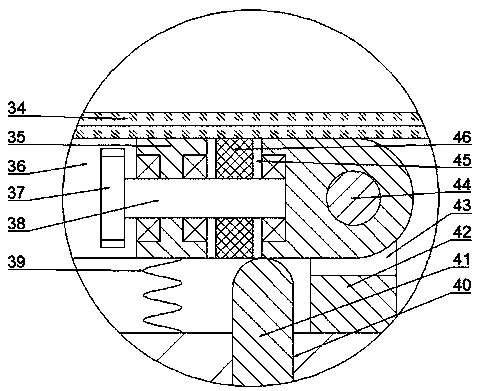

[0024] Combine below Figure 1-7 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0025] combined with Figure 1-7 The described high-strength steel-clad wood production equipment with multi-layer stacking includes a fuselage 11, and the fuselage 11 is provided with a working chamber 14 with an opening upward and through front and rear, and a top cover 10 can be installed on the top of the fuselage 11. , the bottom wall of the working chamber 14 is provided with a first sliding hole 16 with an upward opening, and the first sliding hole 16 is slidingly provided with an extruding rod 18 extending into the working chamber 14, and the extruding rod 18 The top surface can be equipped with multi-layer thin steel 34, and above the multi-layer thin steel 34, there can be pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com