Automatic blank sharpening machine

A blanking machine and automatic technology, applied in the field of ceramic production equipment, can solve the problems of reduced economic benefits, uneven thickness, poor manual blanking effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

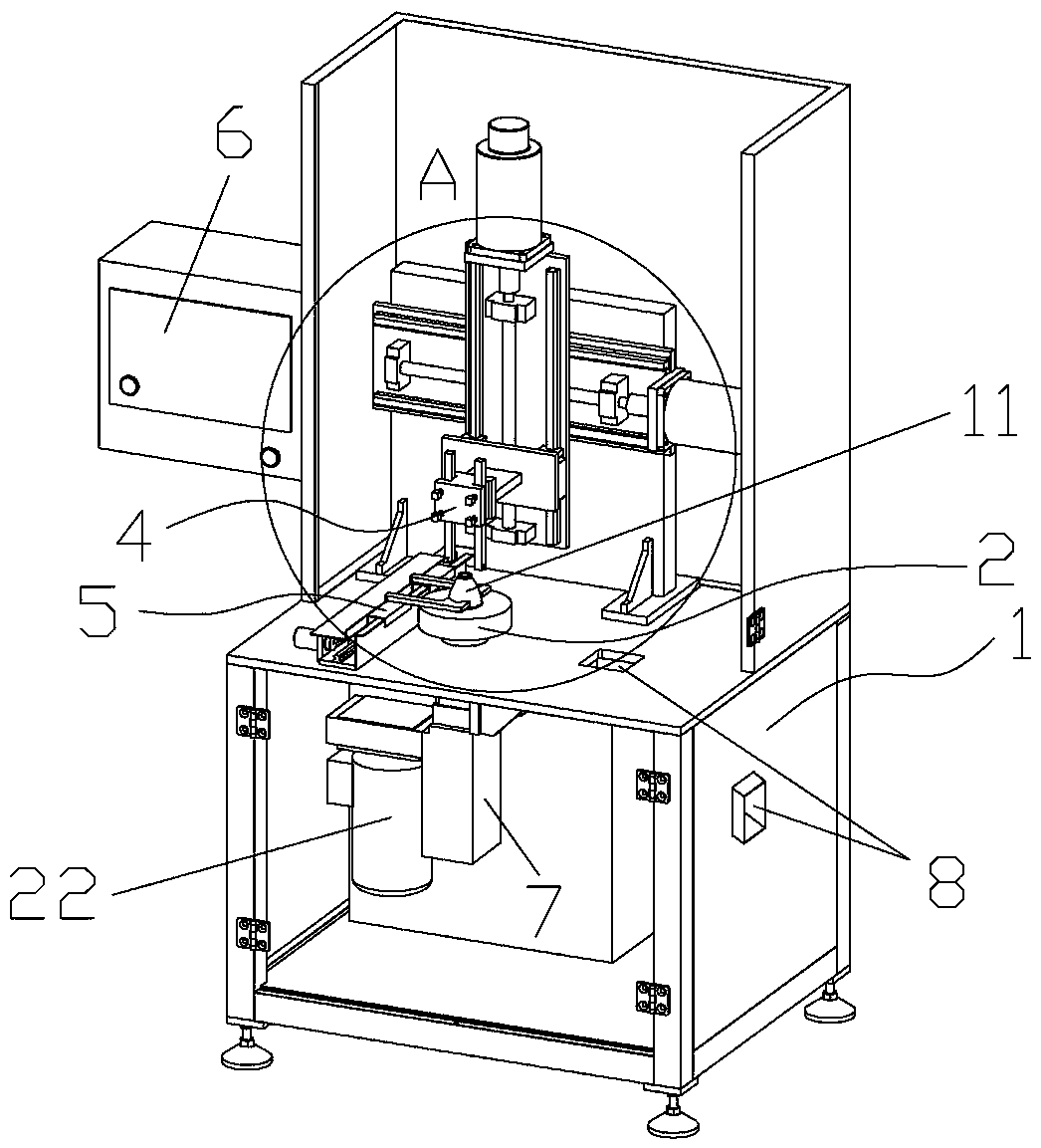

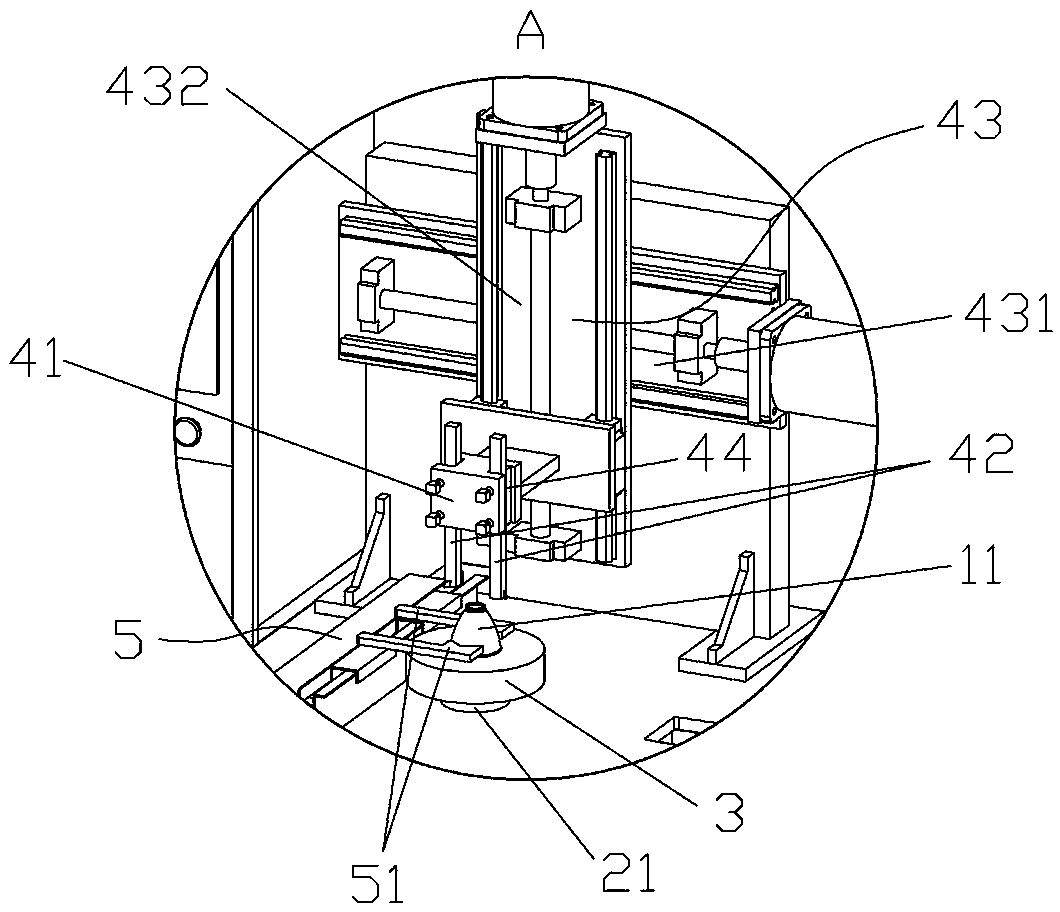

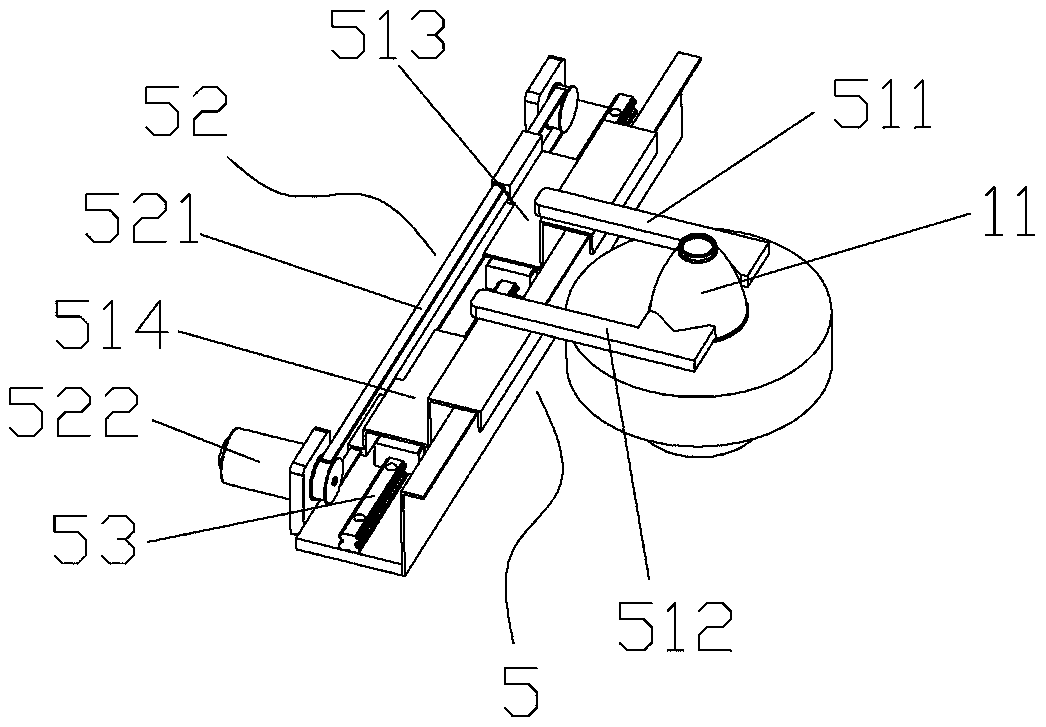

[0019] Such as figure 1 , 2 As shown in , 3 and 4, the automatic billet sharpening machine includes a main frame 1, and the main frame 1 is provided with a rotating operating platform 2, which is used to fix and drive the green body 11 to rotate; the rotating operating platform 2 includes a chassis 21, The chassis 21 is installed on the main frame 1, and the chassis 21 is driven by the driving device 22 to realize rotation. The upper turntable 3 is installed on the chassis 21, and the upper turntable 3 is used to fix and place the green body 11; a cutting mechanism 4 is provided above the rotary operation platform 2 , the cutting mechanism 4 is used to cut the green body 11 to realize the sharp work; the cutting mechanism 4 includes a clamp 41, a cutter 42 is installed on the clamp 41, the clamp 41 is fixed on the main frame 1 through the feed shaft 43, and the feed shaft 43 is used To drive the tool 42 to move; the side of the rotary operation platform 2 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com