Vehicle vibration damping buffering seat based on sliding adjusting mechanism

A sliding adjustment and seat technology, applied in vehicle seats, movable seats, vehicle parts, etc., can solve the problems of height adjustment mechanism adjustment step size, reduced fatigue work efficiency, poor seat impact resistance, etc. Vibration comfort, improved operating efficiency, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

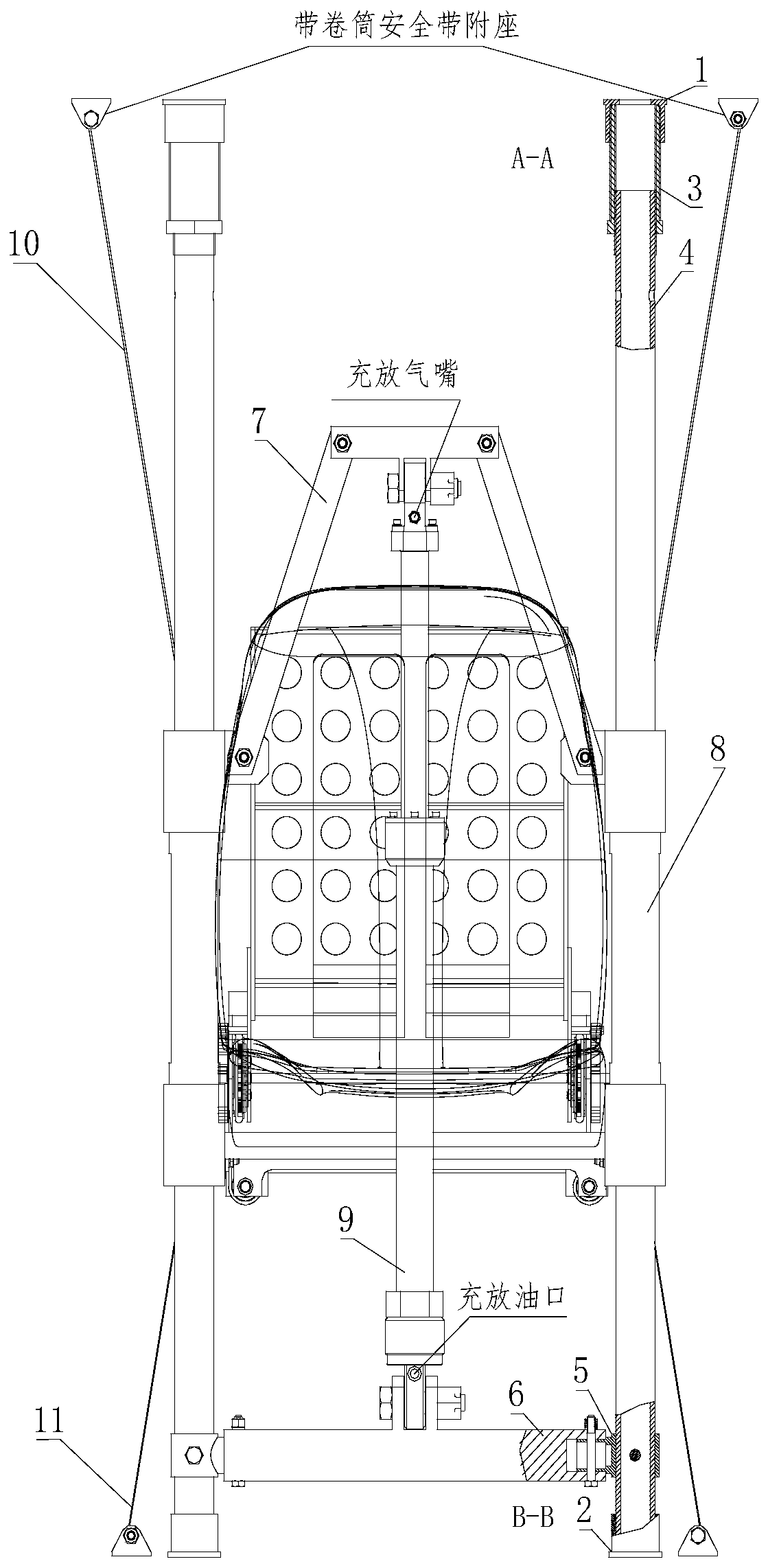

[0030] The present invention provides a vehicle vibration damping buffer seat based on a sliding adjustment mechanism, the vibration damping buffer seat includes a slide rail assembly 13, a seat, a mounting side plate 12, an oil-pneumatic spring 9 and a sliding adjustment mechanism,

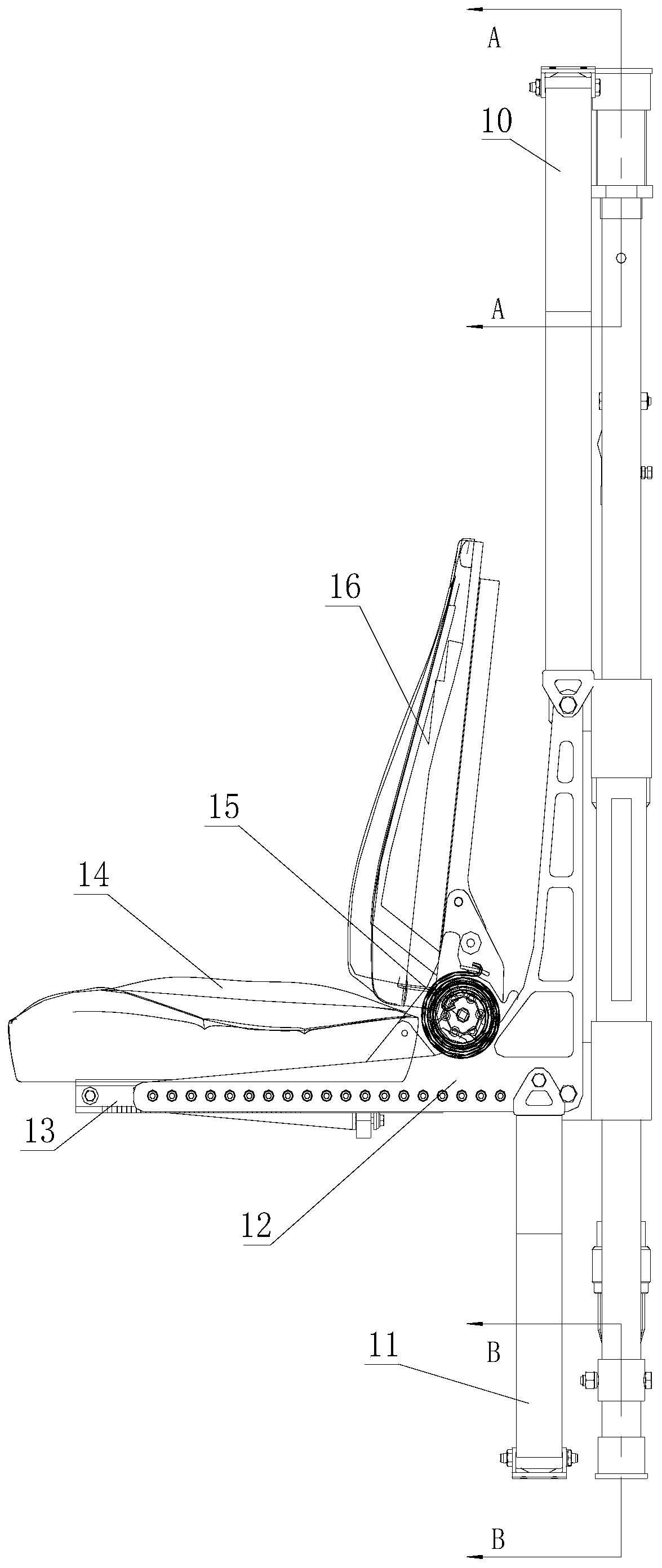

[0031] Wherein, seat is made up of cushion assembly 14, recliner assembly 15 and backrest assembly, and seat is installed on the installation side plate 12 that left and right arranges by slide rail assembly 13.

[0032] Such as figure 1 As shown, the sliding adjustment mechanism includes a sliding column 4 for supporting, a horizontal top beam 7 and a lower supporting beam 6, and a sliding cylinder 8 for sliding; 3;

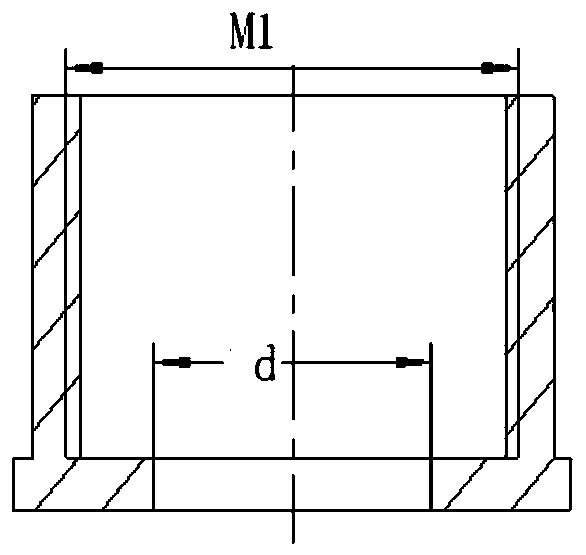

[0033] attached image 3 and 6 As shown, the shape and structure of the upper fixed attachment 1 and the lower fixed attachment 2 are consistent, both bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com