Marine explosion-proofing type liquid nitrogen pump skid

An explosion-proof, liquid nitrogen pump technology, applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of high operating cost, high fuel consumption, high noise, etc., to save waste heat recovery system, The equipment has a wide temperature adaptability and is easy to hoist and move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

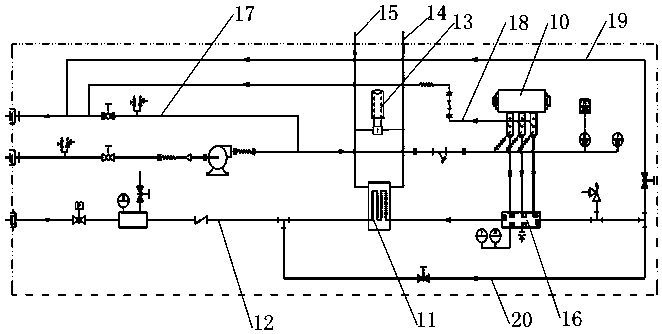

[0024] refer to image 3 , a marine explosion-proof liquid nitrogen pump skid, including a power system, a hydraulic system, a booster device, an evaporator and an explosion-proof heating device. The power system, hydraulic system, supercharging device, evaporator and explosion-proof heating device are all installed on the skid.

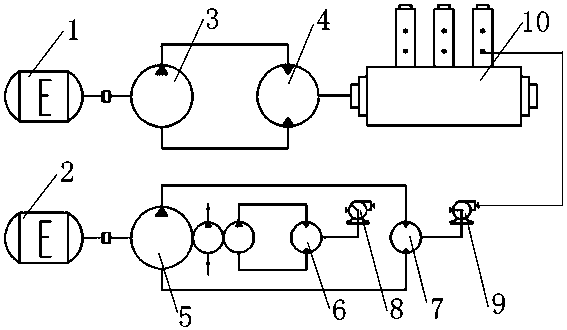

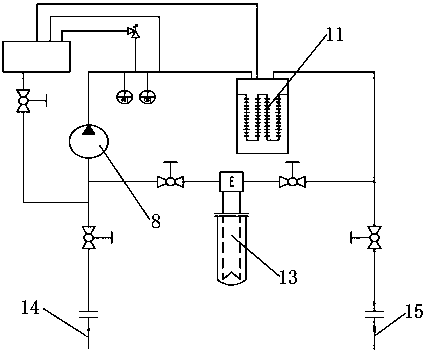

[0025] refer to figure 1 , the power system includes the main motor 1 and the auxiliary motor 2, the hydraulic system includes the main hydraulic pump 3, the main hydraulic motor 4, the auxiliary hydraulic pump 5, the first auxiliary hydraulic motor 6, the second auxiliary hydraulic motor 7 and the sliding vane pump 8, increasing The pressure device includes a centrifugal booster pump 9 and a plunger pump 10. The plunger pump 10 is a three-cylinder plunger pump. The outlet of the centrifugal booster pump 9 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com