Hydraulic system and crane

A hydraulic system and pressure technology, which is applied in the field of construction machinery, can solve problems such as rocker arm support fracture, mechanical steering rod instability and bending, and difficult turning, and achieve the effect of meeting energy-saving needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

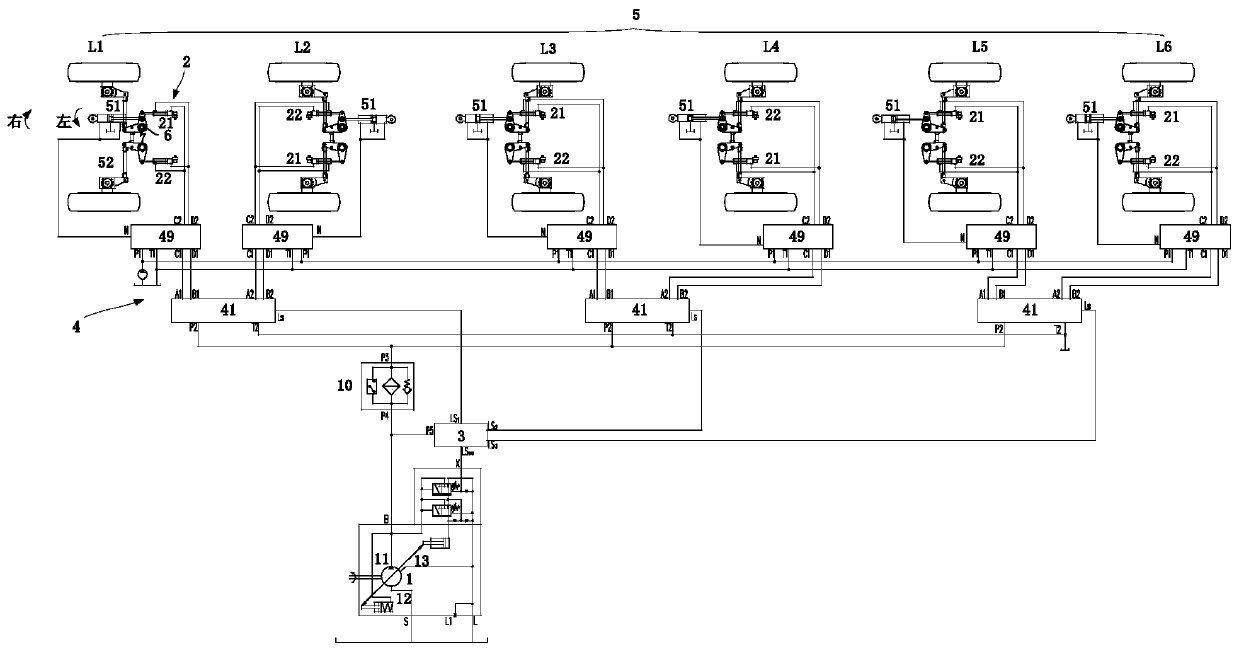

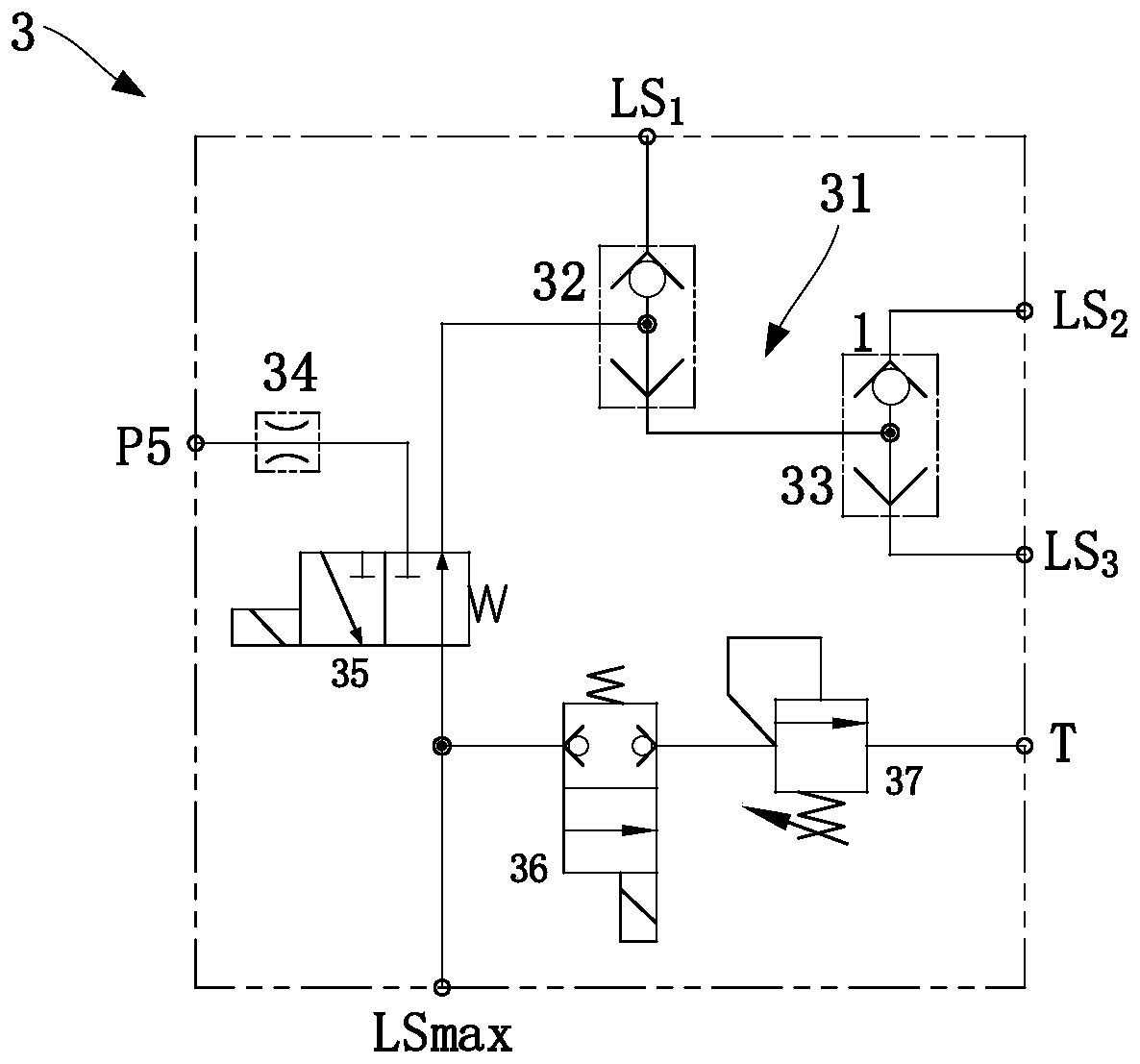

[0065] Combine below Figure 1 to Figure 9 The technical solution provided by the present invention is described in more detail.

[0066] In order to more clearly introduce the various technical solutions of this embodiment, the hydraulic system is used as an example on engineering machinery. Construction machinery is, for example, a crane, especially a kiloton class crane.

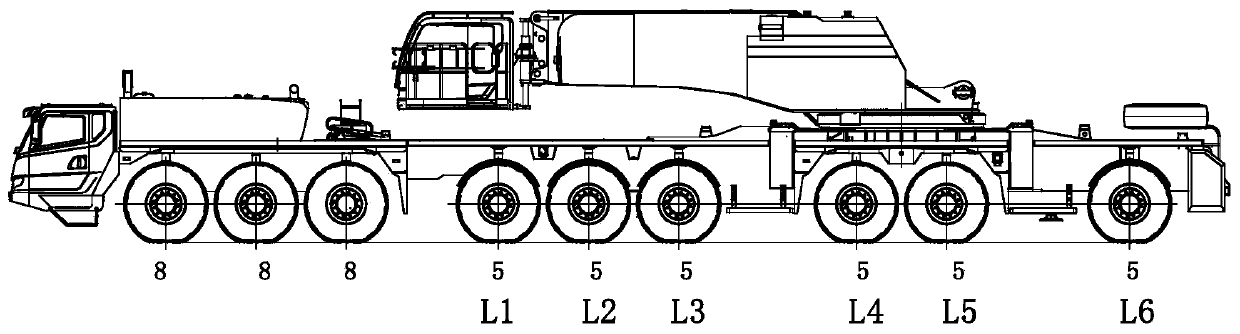

[0067] The crane includes a plurality of axles 5, which are divided into front axles and rear axles according to different driving methods. The number of front axles and rear axles is, for example, multiple. In some embodiments, the number of front axles is three, for example, and the number of rear axles is six. The three front axles are all driven by the mechanical linkage 7, and the six rear axles are driven by the hydraulic system provided by the embodiment of the present invention.

[0068] Compared with the hydraulically driven axles 5 of the crane in the prior art, which must be less than 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com