Aluminum scandium alloy and preparation method thereof

An alloy, aluminum-scandium technology, applied in the field of aluminum-scandium alloy and its preparation, can solve the problems of high reduction equipment requirements, increased production costs, hazards and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

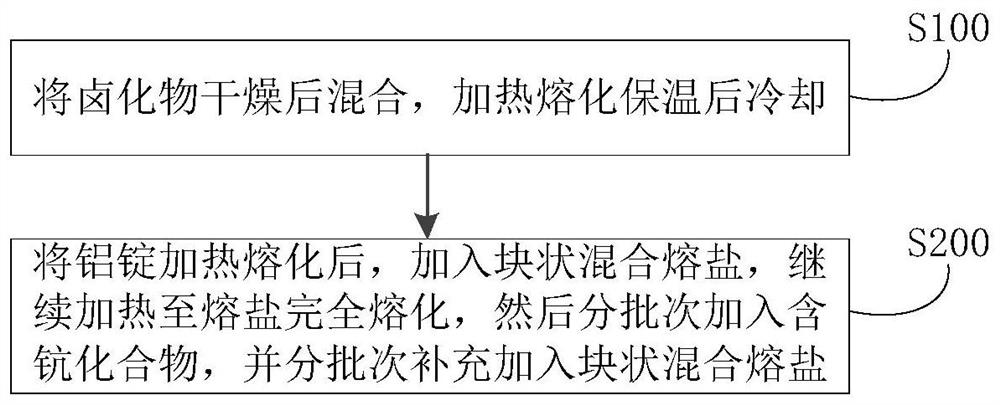

[0035] According to the method for preparing aluminum-scandium alloy in the embodiment of the present invention, the aluminum-scandium alloy is prepared by adopting the two-step method of molten salt preparation and thermal reduction reaction, which effectively solves the problem of oxidation and burning of oxides in the thermal reduction process, and significantly improves the scandium content. The utilization rate and actual recovery rate reduce the production cost. By drying the halides, mixing, heating, melting, heat preservation and then cooling to form a massive mixed molten salt, that is, the original powdery raw materials will be changed into uniformly mixed block raw materials and then added to the thermal reduction reaction, which is conducive to maintaining the thermal reduction reaction process. Stability of medium molten salt system. Moreover, adding supplementary mixed molten salt and scandium-containing compounds in stages during the entire thermal reduction pro...

Embodiment 1

[0039] (1) Dry the 50-mesh powdered halide molten salt at 110°C for 120 minutes, and then follow the NaF:KCl:NaCl:Na 3 AlF 6 = 1:1:2:5 ratio of ingredients, prepared 120g of powdered mixed molten salt, mixed evenly, put it into a crucible and heated to 850°C, melted and stirred, kept warm for 20min, poured into a container to cool, and obtained Block mixed molten salt;

[0040] (2) Weigh 200g of aluminum ingot, put it into a graphite crucible and heat it to 700°C for melting, then add 100g of block mixed molten salt therein, heat until the block of molten salt is completely melted, and start the reduction reaction at 900°C, and Weigh 5g of scandium-containing compound in 10min and add it to the melt, the Sc in the scandium-containing compound 2 o 3 : ScF 3 =3:0.5, the whole process is stirred once every 20min, each time stirring for 1min, and 10g block mixed molten salt is added every 15min, after the reduction reaction for 60min, the mixed molten salt solution after the u...

Embodiment 2

[0042] (1) Dry the 200-mesh powdered halide molten salt at 110°C for 120 minutes, and then follow the NaF:KCl:NaCl:Na 3 AlF 6 = 1:2:2:6 ratio of ingredients, prepared 350g of powdery mixed molten salt, mixed evenly, put it into a crucible and heated to 900°C, melted and stirred, kept warm for 30min, poured into a container to cool, and obtained Block mixed molten salt;

[0043] (2) Weigh 500g of aluminum ingot, put it into a graphite crucible and heat it to 700°C for melting, then add 300g of block mixed molten salt therein, heat until the block of molten salt is completely melted, and start the reduction reaction at 1000°C, and Weigh 10g of scandium-containing compound in 10min and add it into the melt, the Sc in the scandium-containing compound 2 o 3 : ScF 3 = 3:1, the whole process is stirred once every 20 minutes, each time stirring for 1 minute, and 20 g of block mixed molten salt is added every 15 minutes. After the reduction reaction for 30 minutes, the mixed molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com