Electromechanical brake actuator for rail vehicle and rail vehicle

An electro-mechanical braking and rail vehicle technology, applied in the field of rail vehicle braking system, can solve the problems of inability to achieve precise control of braking force, inability to achieve rail vehicle braking and anti-skid function, etc., achieve constant clearance, increase reliability, Achieve precise control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

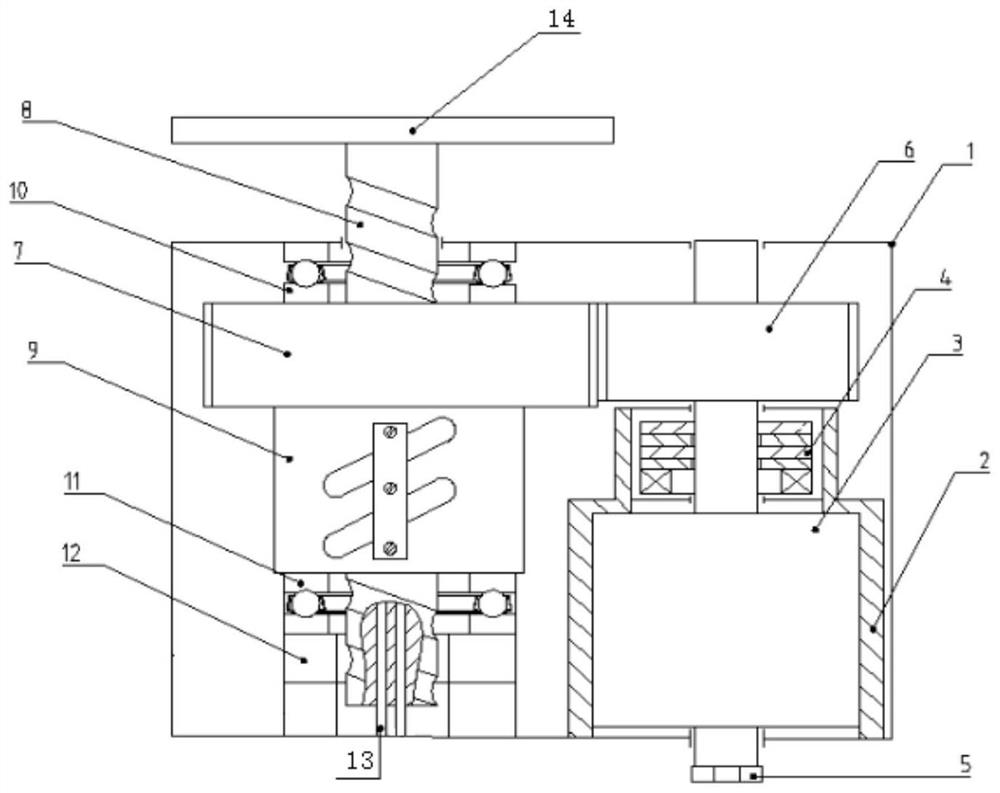

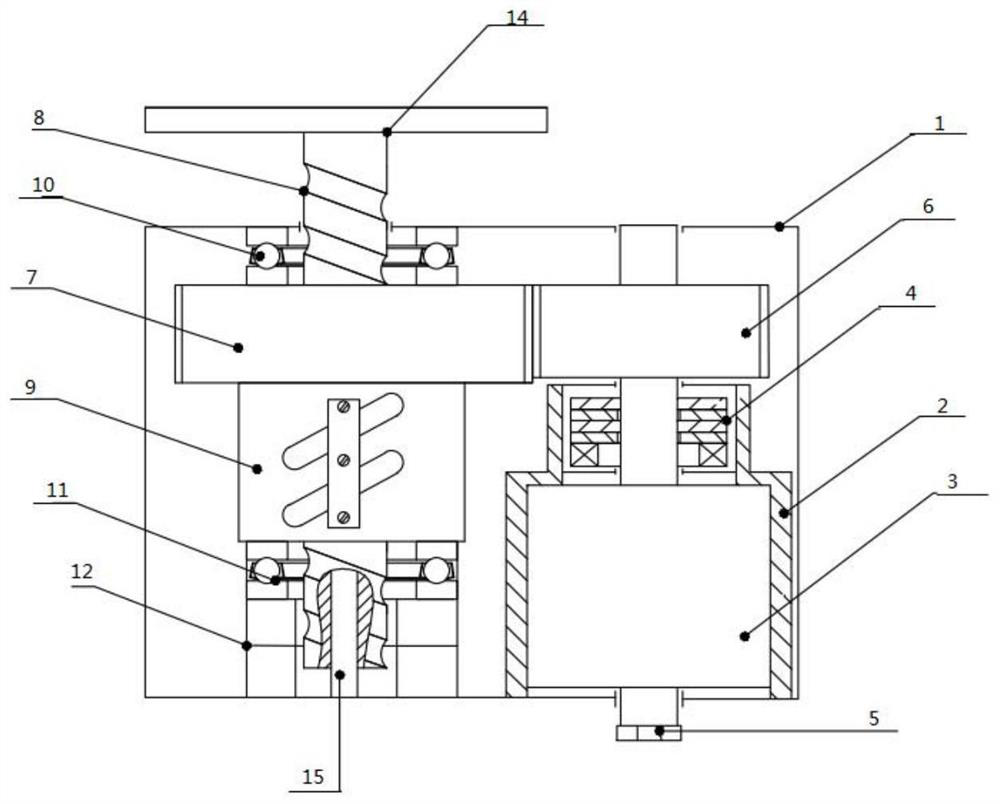

[0036] A rail vehicle electromechanical brake actuator, the actuator includes a motor 3, one end of the motor 3 is connected with a gear transmission system, the gear transmission system includes a high-speed gear 6 and a low-speed gear 7, the gear transmission One end of the system is connected with a screw drive, which includes a lead screw 8 and a screw nut 9, and one end of the screw drive in the direction of travel is fixedly connected with a brake pusher 14, so A force sensor 12 is provided at the other end of the screw drive in the direction of travel.

[0037] Such as figure 1As shown, the actuator includes a housing 1, which is formed by processing aluminum or stainless steel, and has an installation interface at the end to connect with the body of the electromechanical brake caliper. A motor 3 is installed inside the shell 1. The motor 3 is preferably a permanent magnet inductive brushless motor, which includes a motor body and a rotor output shaft: a manual relief ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com