Three-degree-of-freedom gear continuously variable transmission device

A technology of continuously variable transmission and degree of freedom, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve problems such as increased cost, complex structure, no good results and scientific research projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

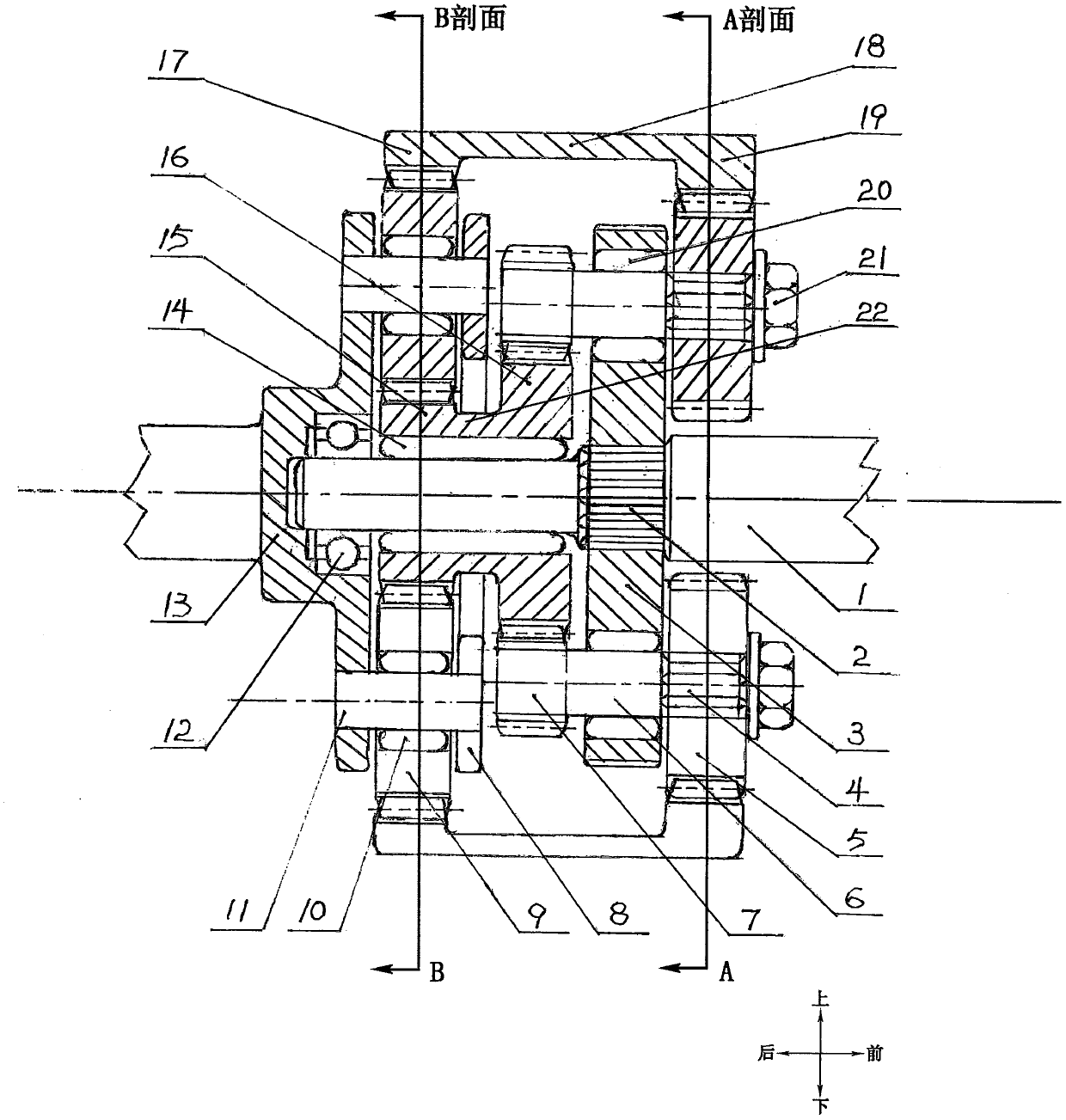

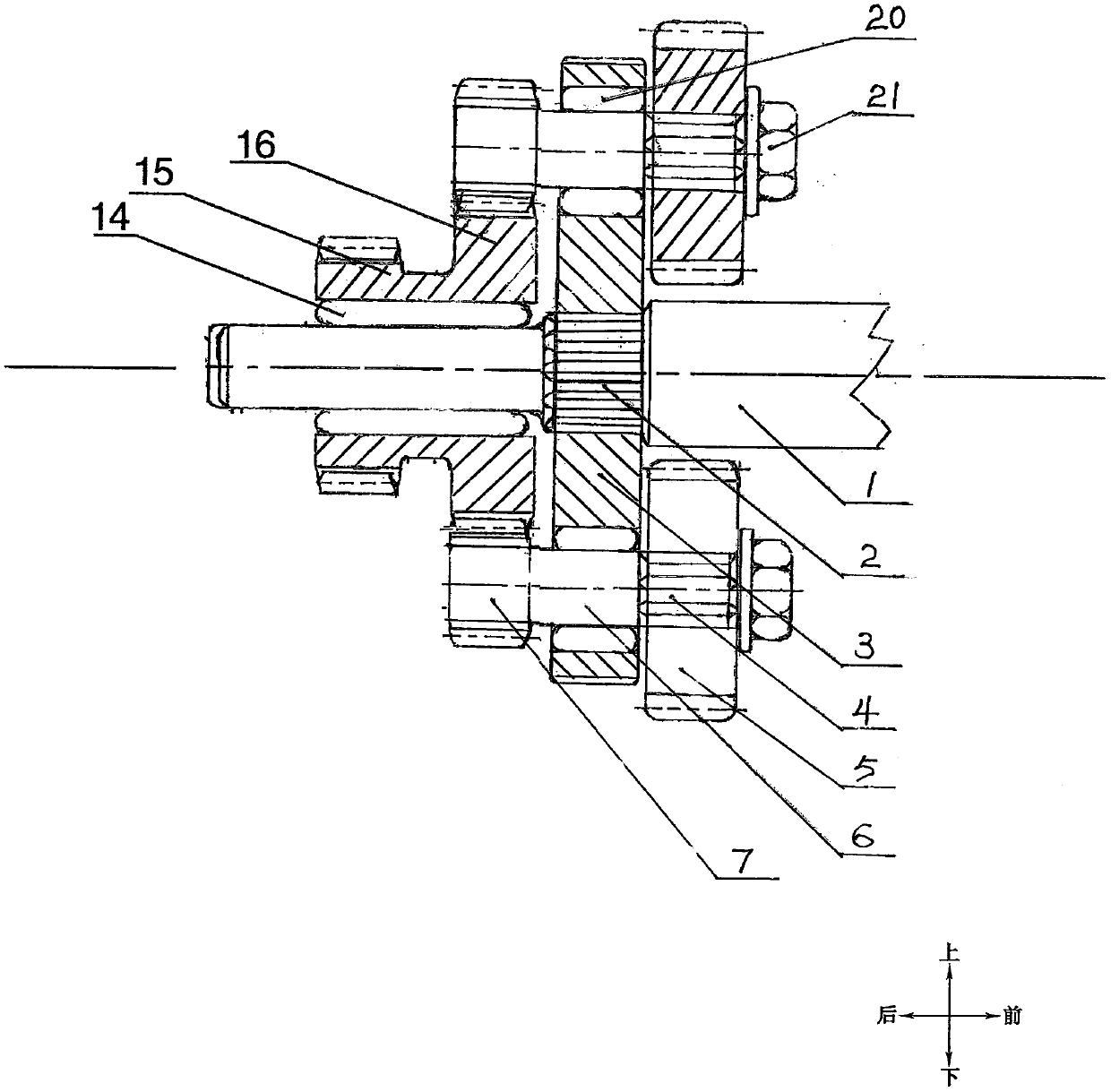

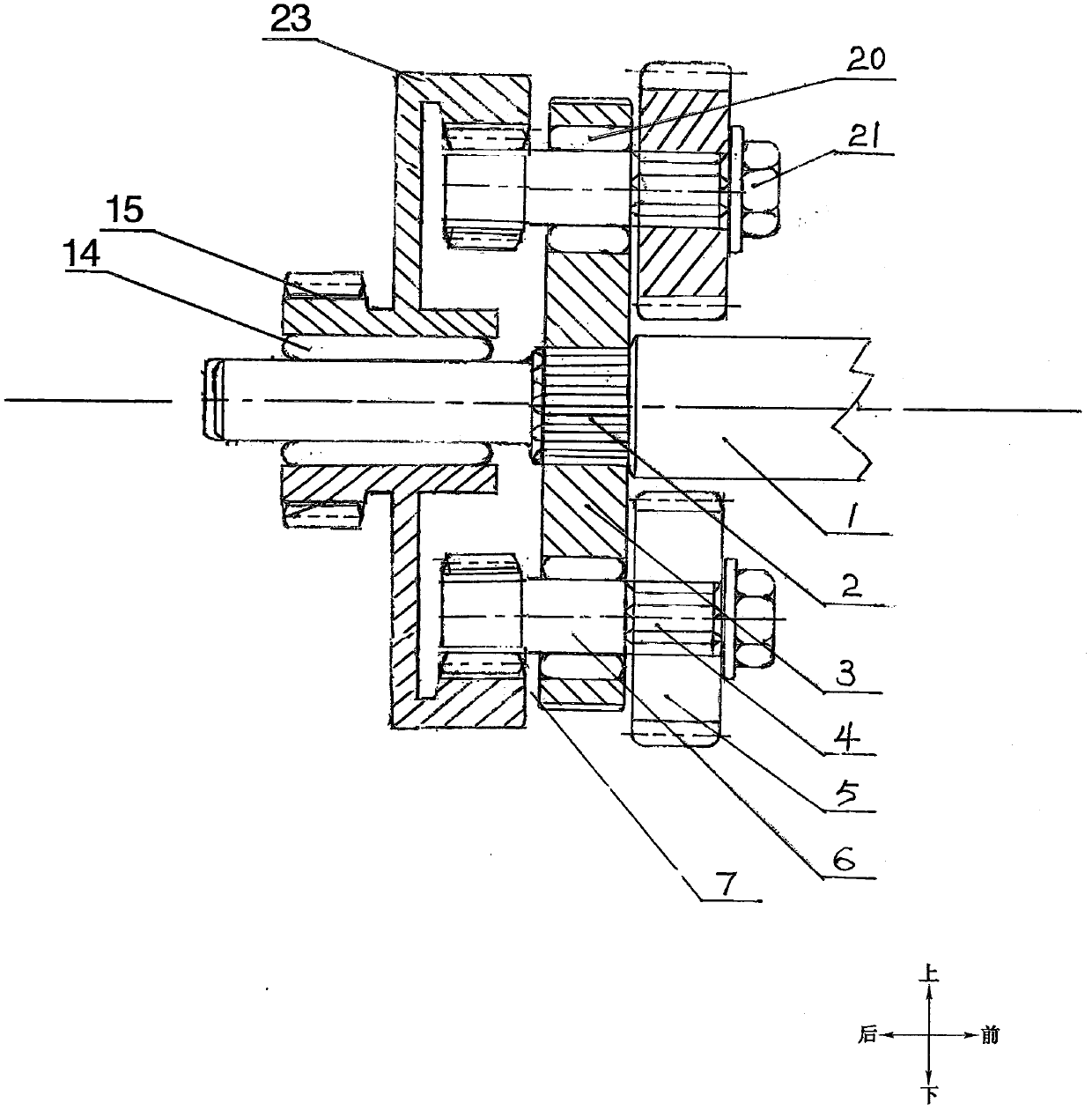

[0014] Such as figure 1 ... Image 6As shown, the present invention is a 3-degree-of-freedom all-gear continuously variable transmission device. This embodiment is designed for urban buses and large trucks in detail. The continuously variable transmission device is on a central axis, from front to rear Set the power input shaft (1) in sequence, set the rotating wheel (3) on the power input shaft (1) through the assembly spline (2), set the gear shaft (6) on the rotating wheel (3), and set the gear shaft ( 6) is set on the rotary wheel (3) through the needle bearing (20), the speed-up gear (5) is installed on the spline shaft (4) at the front end of the gear shaft (6) by the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com