Mechanical sealing device of high-speed high-pressure hydraulic pump

A mechanical seal device and hydraulic pump technology, applied in the field of mechanical hydraulics, can solve the problems of poor vibration and impact resistance, low rotation speed and sealing specific pressure, and poor reliability, so as to increase vibration and impact resistance and reduce specific power and specific pressure, increasing life and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

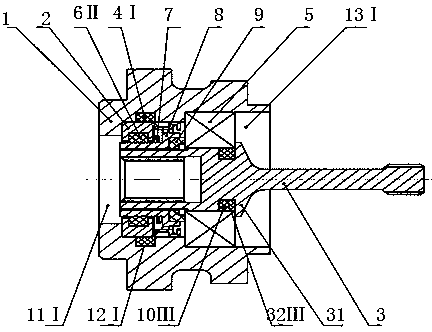

[0019] Such as figure 1 As shown, a mechanical seal device of a high-speed and high-pressure hydraulic pump includes a housing 1, a rear cover 2, and a transmission shaft 3. The housing 1 is provided with a through hole 11I, and the transmission shaft 3 is installed with a clearance fit with the through hole 11I. The housing 1 The inner side is provided with a ring groove 12I, the rubber sealing ring 4I is placed in the ring groove 12I, the back cover 2 is installed in the position near the front end of the casing 1, the outer side of the back cover 2 is closely attached to the rubber sealing ring 4I, and the casing 1 The rear end is provided with a counterbore 13I, the outer ring of the deep groove ball bearing 5 is installed with an interference fit with the counterbore 13I13, and the inner ring of the bearing 5 is installed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com