Oil seal and manufacturing method thereof

An oil seal, integrated technology, applied in the field of oil seal and its manufacturing, can solve the problems of increasing maintenance frequency and maintenance cost, increasing the manufacturing cost of mechanical equipment, poor oil storage capacity of lubricating grease, etc., so as to reduce the dependence on machining accuracy and improve the oil sealing effect. and service life, the effect of reliable oil storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

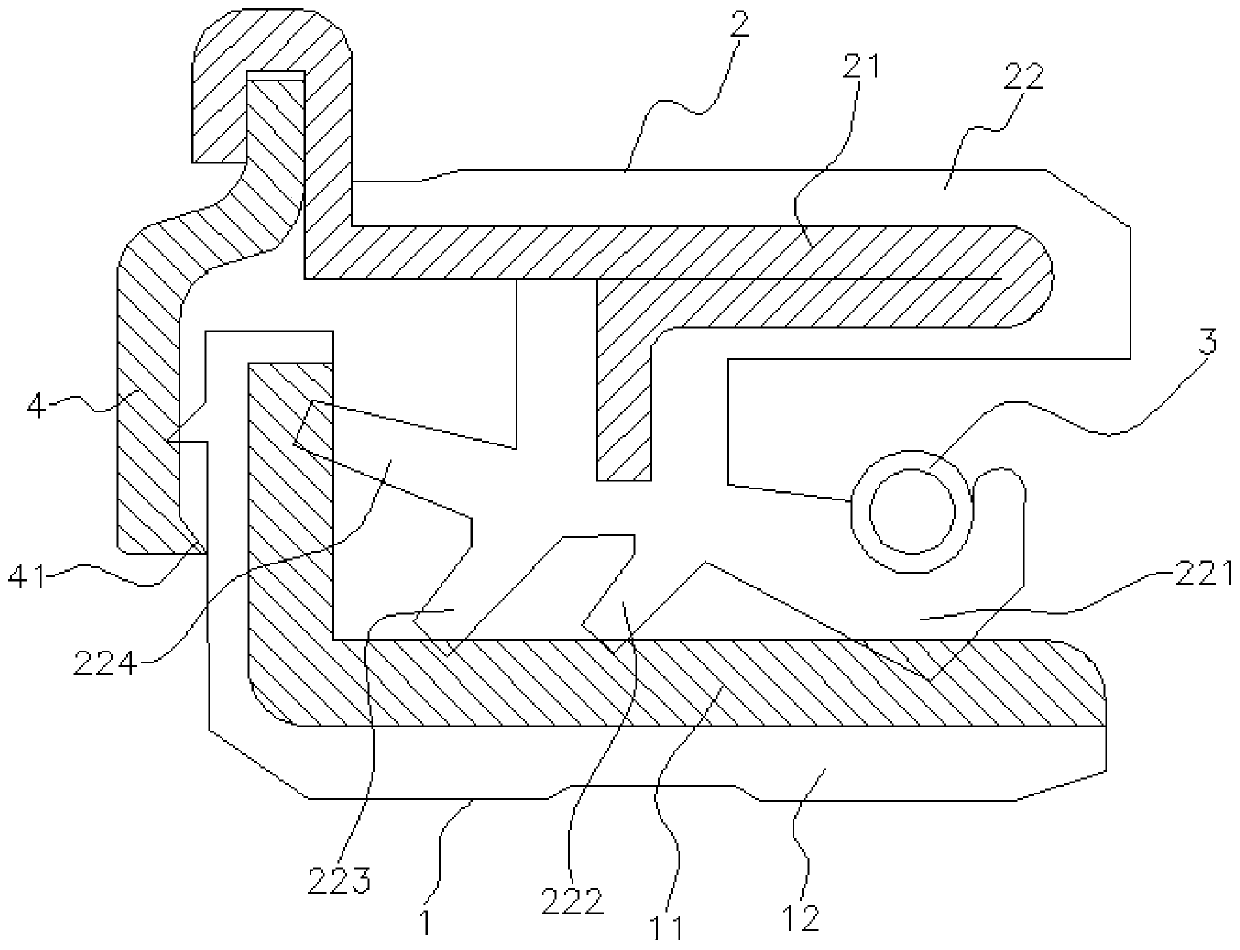

[0033] Such as figure 1 As shown, an embodiment of the present invention is: an oil seal, comprising:

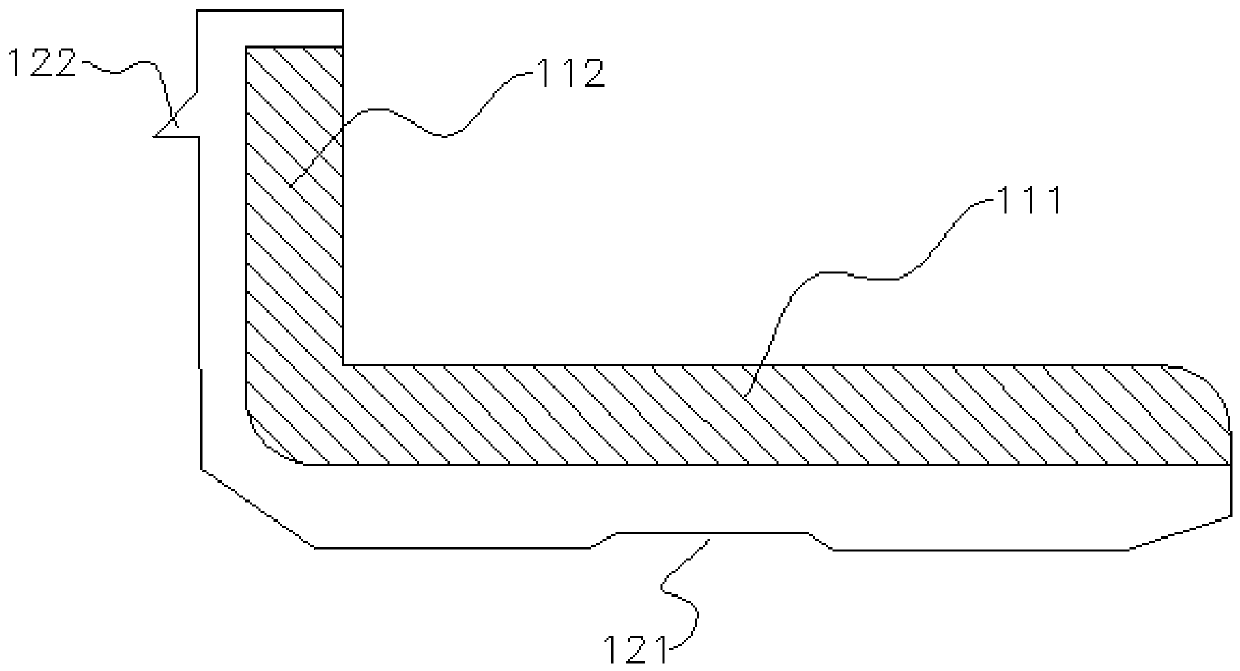

[0034] The inner ring assembly 1 includes an integrated inner ring skeleton 11 and an inner ring rubber body 12. The inner ring skeleton 11 includes an inner skeleton horizontal part 111 and an inner skeleton vertical part 112 surrounding the axis to form a ring. The inner skeleton The vertical part 112 extends vertically outward from one end of the horizontal part 111 of the inner frame; the inner ring rubber body 12 is wrapped on the inner surface of the horizontal part 111 of the inner frame and on the side of the vertical part 112 of the inner frame far away from the horizontal part of the inner frame; The outer circumferential surface of the horizontal part of the inner skeleton 111 and the side surface of the vertical part of the inner skeleton 112 and the horizontal part of the skeleton are smooth surfaces;

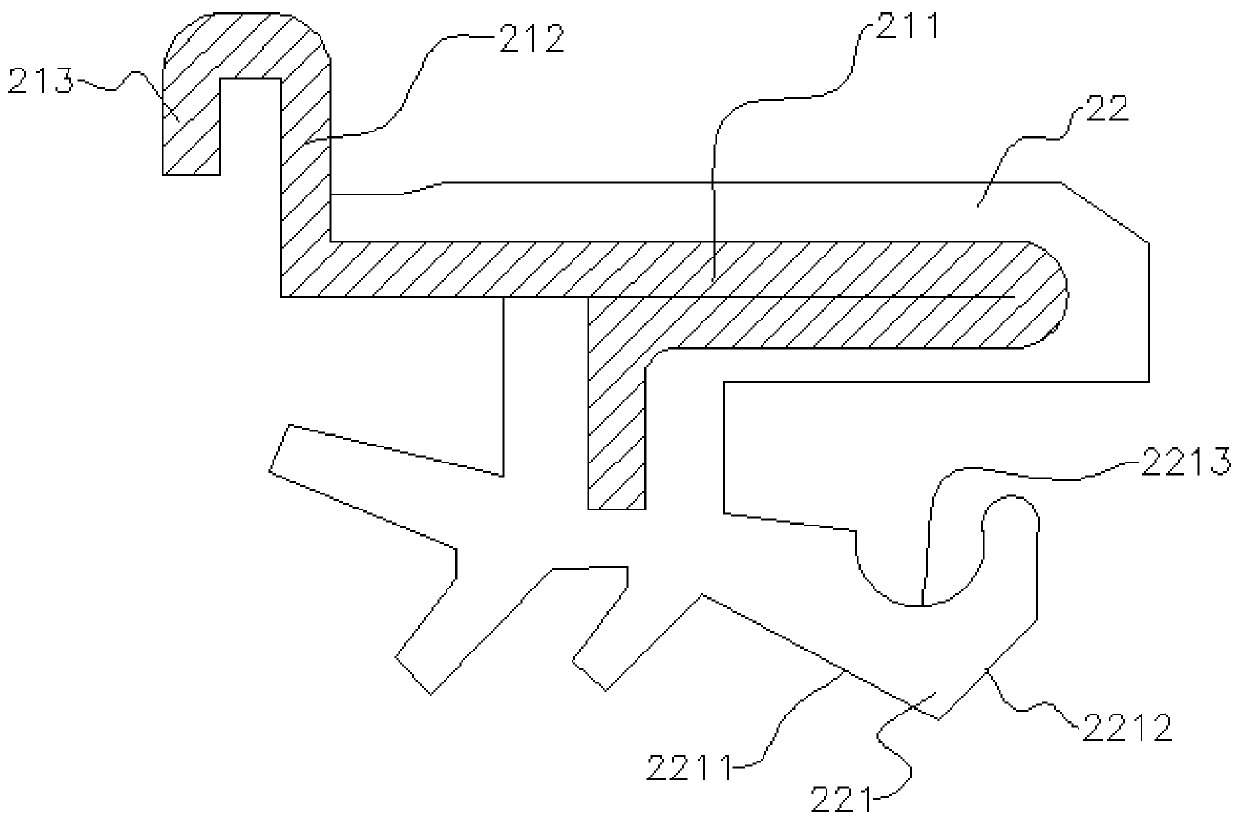

[0035] The outer ring assembly 2 is sheathed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com