Safety circuit and gas water heater

A safety circuit and resistance technology, applied in fluid heaters, lighting and heating equipment, valve details, etc., can solve the problem of triode output high level, controller pin state uncertain, gas solenoid valve switch state uncertain state And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

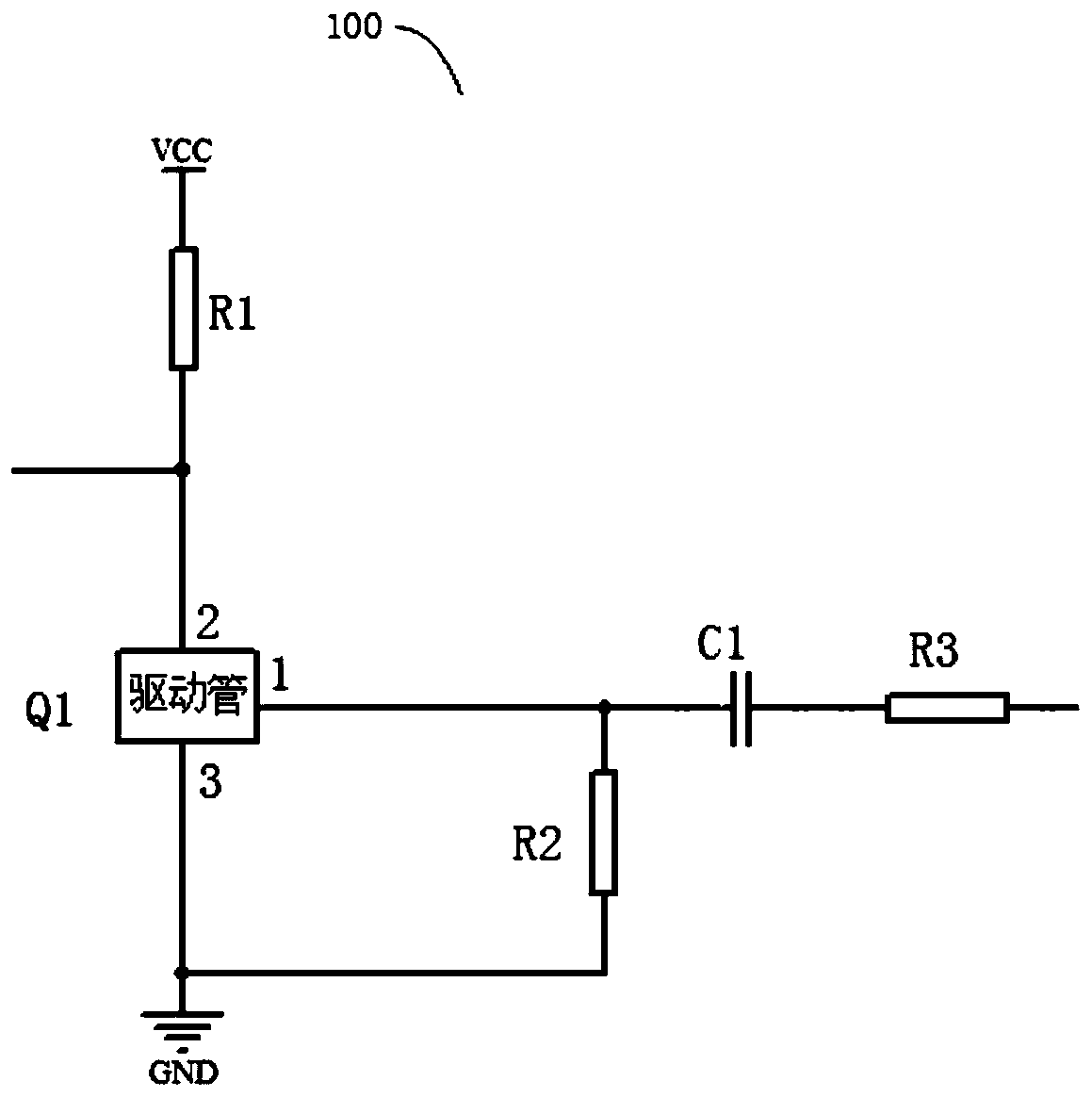

[0036] Please refer to figure 1 , this embodiment proposes a safety circuit 100, which can be applied to gas water heaters. By setting the safety circuit 100, it can effectively solve the problem of effectively ensuring the definite state of the gas solenoid valve drive and the solenoid valve when the software control logic of the water heater fails. The closed state of the water heater, etc., thereby improving the safety and reliability of the water heater. The safety circuit 100 will be described in detail below.

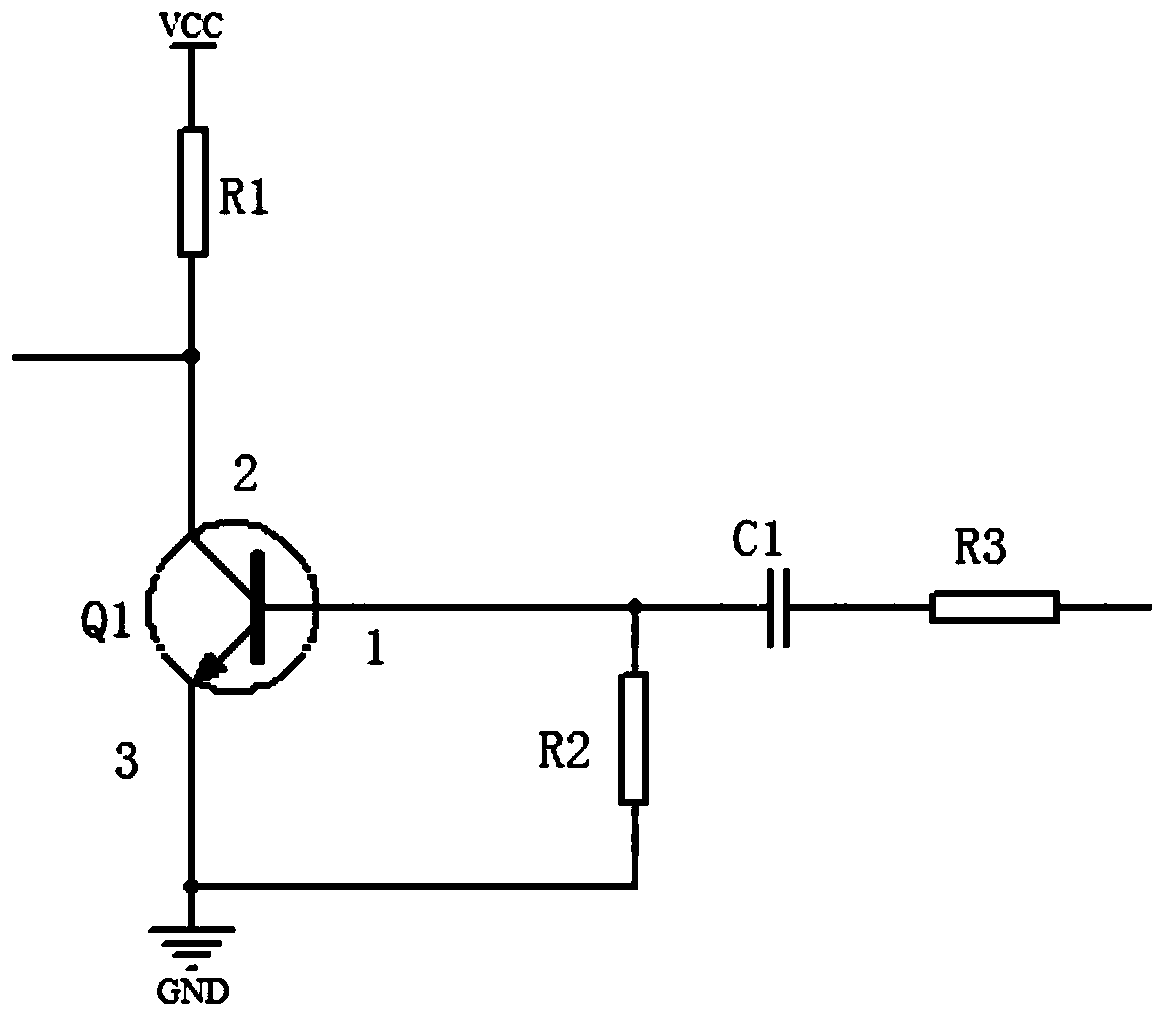

[0037] Such as figure 1 As shown, the safety circuit 100 includes a driving transistor Q1, a capacitor C1, a first resistor R1 and a second resistor R2, wherein the first end of the driving transistor Q1 is connected to one end of the capacitor C1, and the other end of the capacitor C1 is used as a signal input terminal for connecting to the controller. The second end of the driving transistor Q1 is connected to one end of the first resistor R1, and the other e...

Embodiment 2

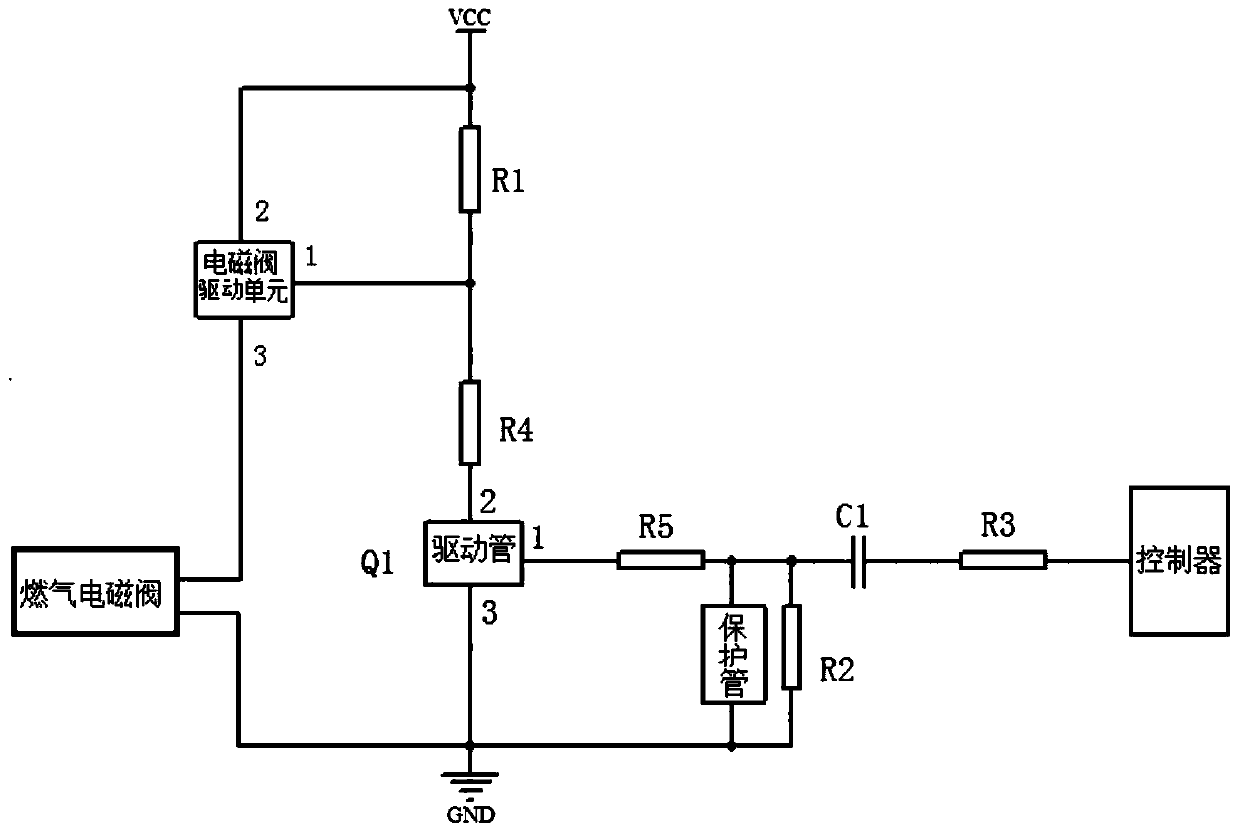

[0058] Please refer to figure 1 , the present embodiment proposes a gas water heater, including a safety circuit, and the safety circuit is used to control the opening or closing state of the gas solenoid valve in the gas water heater. Wherein, the safety circuit may adopt the safety circuit 100 in the first embodiment above.

[0059] Exemplarily, the safety circuit 100 includes a driving transistor Q1, a capacitor C1, a first resistor R1 and a second resistor R2, the first end of the driving transistor Q1 is connected to one end of the capacitor C1, and the other end of the capacitor C1 It is used as a signal input terminal for connecting to the controller; the second end of the driving tube Q1 is connected to one end of the first resistor R1, the other end of the first resistor R1 is used for connecting to a power supply, and the second end is used as a signal The output end is used to connect the solenoid valve driving unit; the third end of the driving tube Q1 is grounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com