Method and apparatus for measuring rotation speed based on fusion of several kinds of characteristic data

A characteristic data and rotational speed measurement technology, which is applied to measuring devices, devices using electric/magnetic methods, linear/angular velocity measurement, etc., can solve problems such as unstable methods of measuring rotational speed, troublesome installation of existing devices, and low accuracy , to achieve the effect of solving instability and low accuracy, improving the accuracy of speed measurement, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

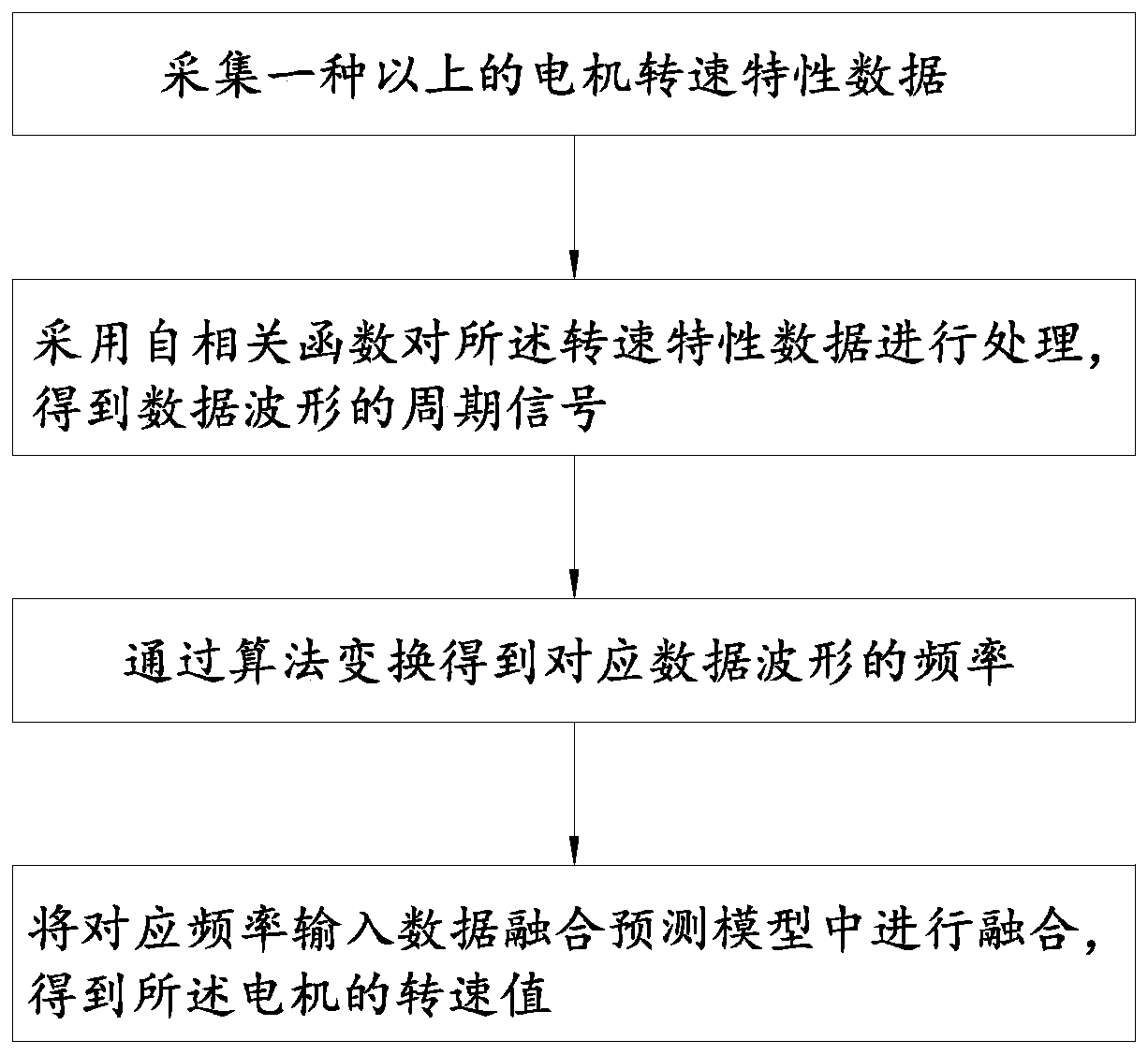

[0031] see figure 1 , a method for measuring a rotational speed by fusing multiple characteristic data, the method comprising:

[0032] Collect more than one type of motor speed characteristic data;

[0033] Processing the rotational speed characteristic data by using an autocorrelation function to obtain a periodic signal of the data waveform;

[0034] The frequency of the corresponding data waveform is obtained through algorithm transformation;

[0035] The corresponding frequency is input into the data fusion prediction model for fusion to obtain the rotational speed value of the motor.

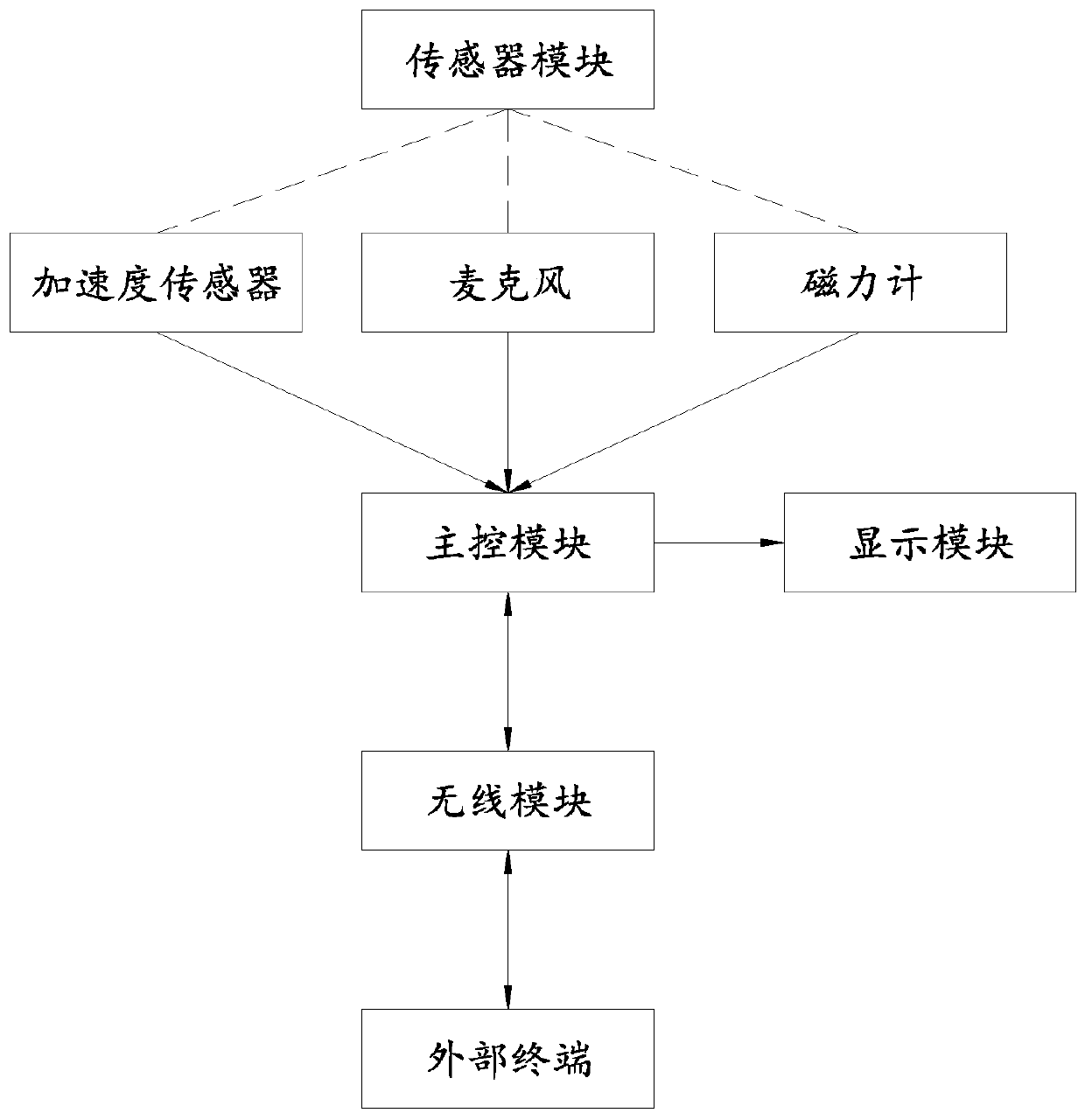

[0036] In this embodiment, the magnetic field data, sound data and vibration data are collected through the Nyquist sampling theorem.

[0037] Processing the rotational speed characteristic data further includes: removing white noise from the collected rotational speed characteristic data by means of low-pass filtering or wavelet processing.

[0038] The algorithm is a fast Fourier tra...

Embodiment 2

[0050] This embodiment specifies that the predicted value of the sound data is A, the predicted value of the vibration data is B, and the predicted value of the magnetic field data is C, wherein the magnetic field data, sound data and vibration data are not disturbed, and the magnetic field data, sound data and vibration data are set The corresponding weights are the same, and the final speed value is (A+B+C) / 3.

[0051] The rest of the steps and devices are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0053] This embodiment specifies that the predicted value of sound data is A, the predicted value of vibration data is B, and the predicted value of magnetic field data is C, wherein the predicted value of sound data is A=0 when the sound data is disturbed, and the predicted values of vibration data and magnetic field data are normal. The predicted value of the sound data is discarded, and the final speed value is (B+C) / 2;

[0054] The rest of the steps and devices are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com