Rotary compressor and manufacturing method for rotary compressor

A manufacturing method and technology for compressors, which can be applied to machines/engines, rotary piston machines, mechanical equipment, etc., can solve problems such as impeding reciprocating motion of blades and sliding loss, reducing pressure loss, suppressing sliding resistance, and improving flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] The rotary compressor related to this embodiment is, for example, a multi-stage cylinder type or a single cylinder type rotary compressor. In the refrigeration cycle, in order to compress the refrigerant and send the compressed refrigerant to the refrigeration circuit And used. In the following description, a multi-stage cylinder type rotary compressor will be described as an example.

[0024]

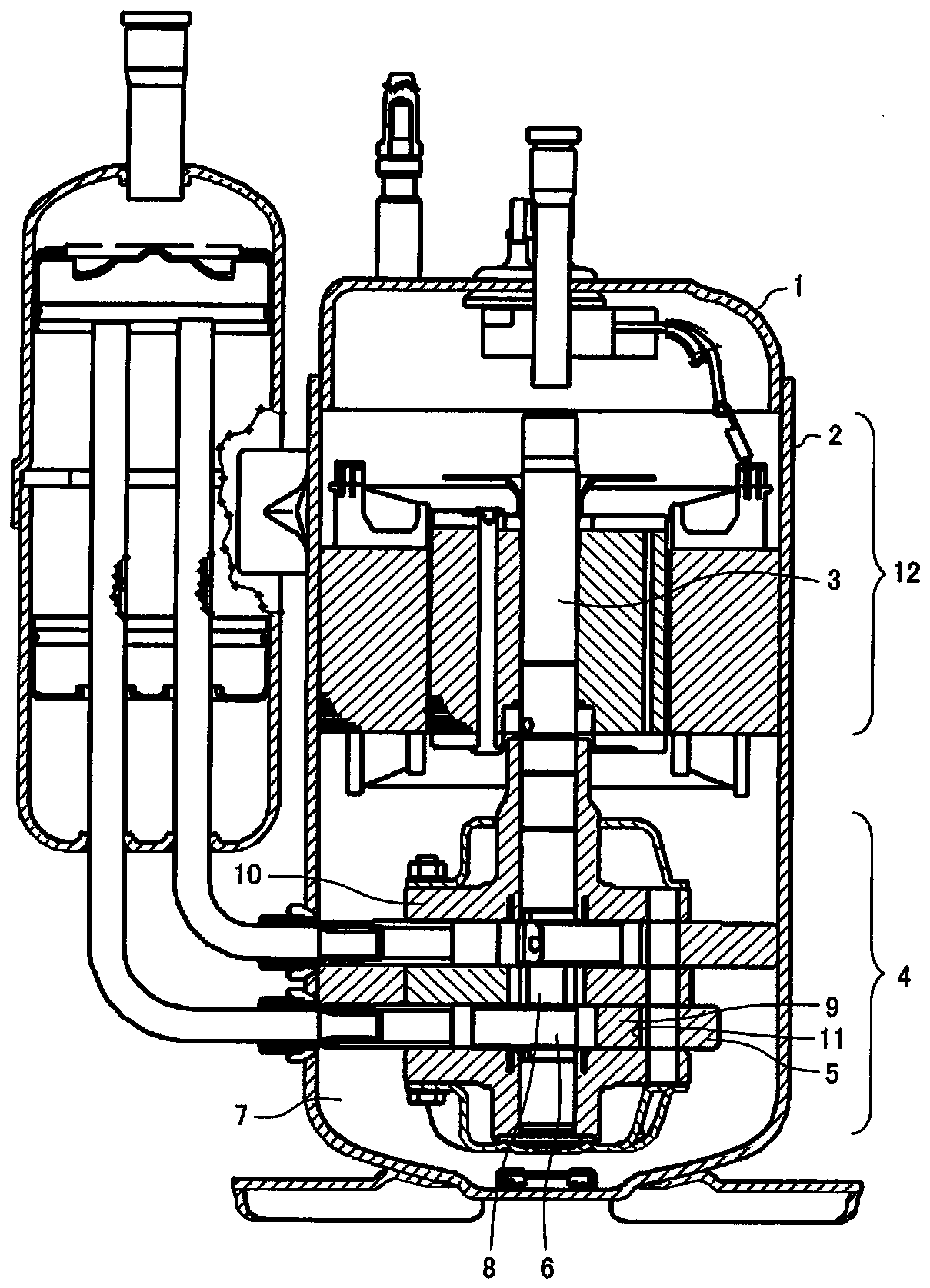

[0025] figure 1 It is a schematic diagram of the rotary compressor 1 concerning this embodiment. Such as figure 1 As shown, the rotary compressor 1 has a cylindrical airtight container 2 made of steel plate, an electric unit 12 arranged above the airtight container 2 , and a rotary compression mechanism 4 arranged below the electric unit 12 .

[0026] The electric unit 12 has a crankshaft 3 and is connected to a rotary compression mechanism unit 4 disposed below the electric unit 12 via the crankshaft 3 . The electric unit 12 is a driving source for rotating the rotary com...

Embodiment approach 2

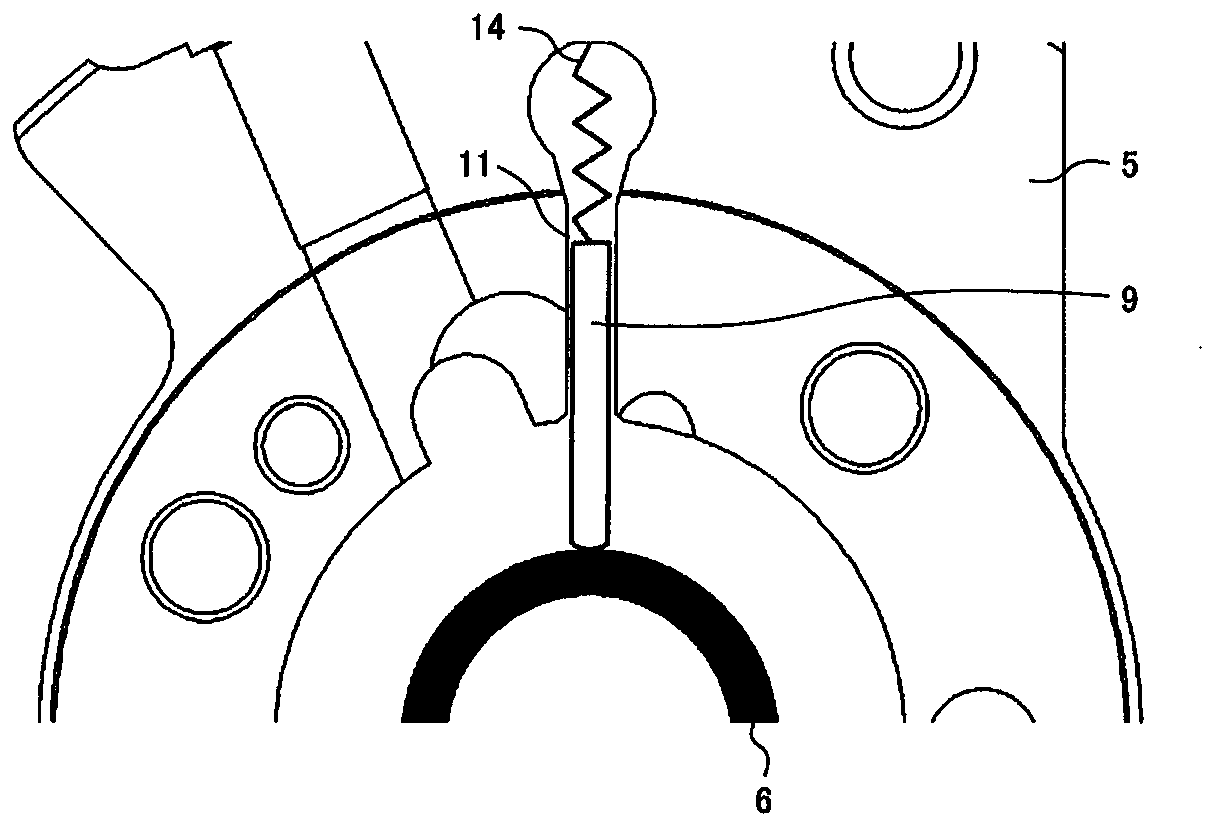

[0055] The rotary compressor 1 according to Embodiment 2 will be described. The rotary compressor 1 of the present embodiment differs from the first embodiment in that a concave shape R is formed on the inner surface of the vane attachment groove 11 . In addition, in this embodiment, the difference from Embodiment 1 will be described, and the same reference numerals will be attached to the same parts as Embodiment 1, and description will be omitted.

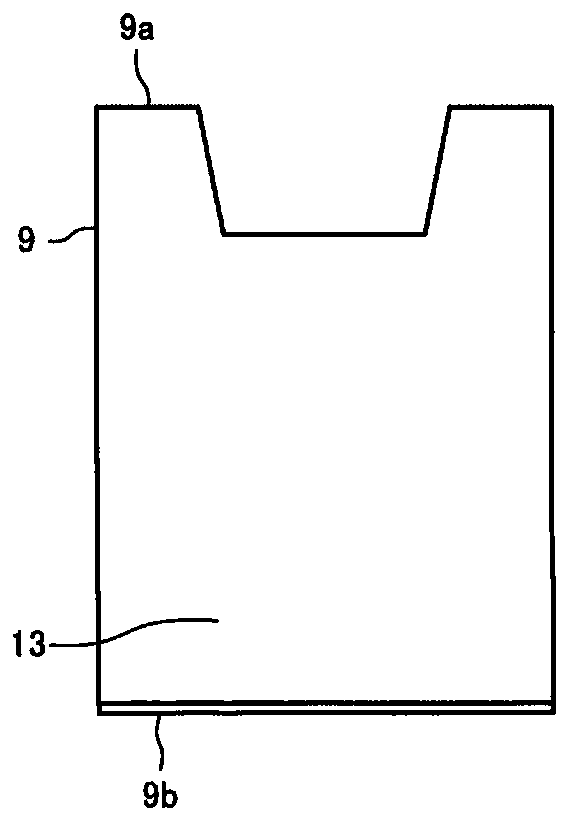

[0056] Figure 7 is a cross-sectional curve of the side surface of the vane mounting groove 11 of the rotary compressor 1 according to the present embodiment. in addition, Figure 8 is the cross-sectional curve of the side surface of the conventional blade mounting groove. Figure 7 with Figure 8 and Figure 4 with Figure 5 Similarly, the horizontal axis shows the dimension in the longitudinal direction of the blade mounting groove 11 , and the vertical axis represents the surface texture of the cross section perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com