Punch for hot air pressure forming of metal pipe

A technology of metal pipe fittings and punches, which is applied in the field of punches for hot air forming of metal pipe fittings, can solve problems such as high noise and safety, and achieve the effect of avoiding safety hazards, reducing safety hazards, and ensuring the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

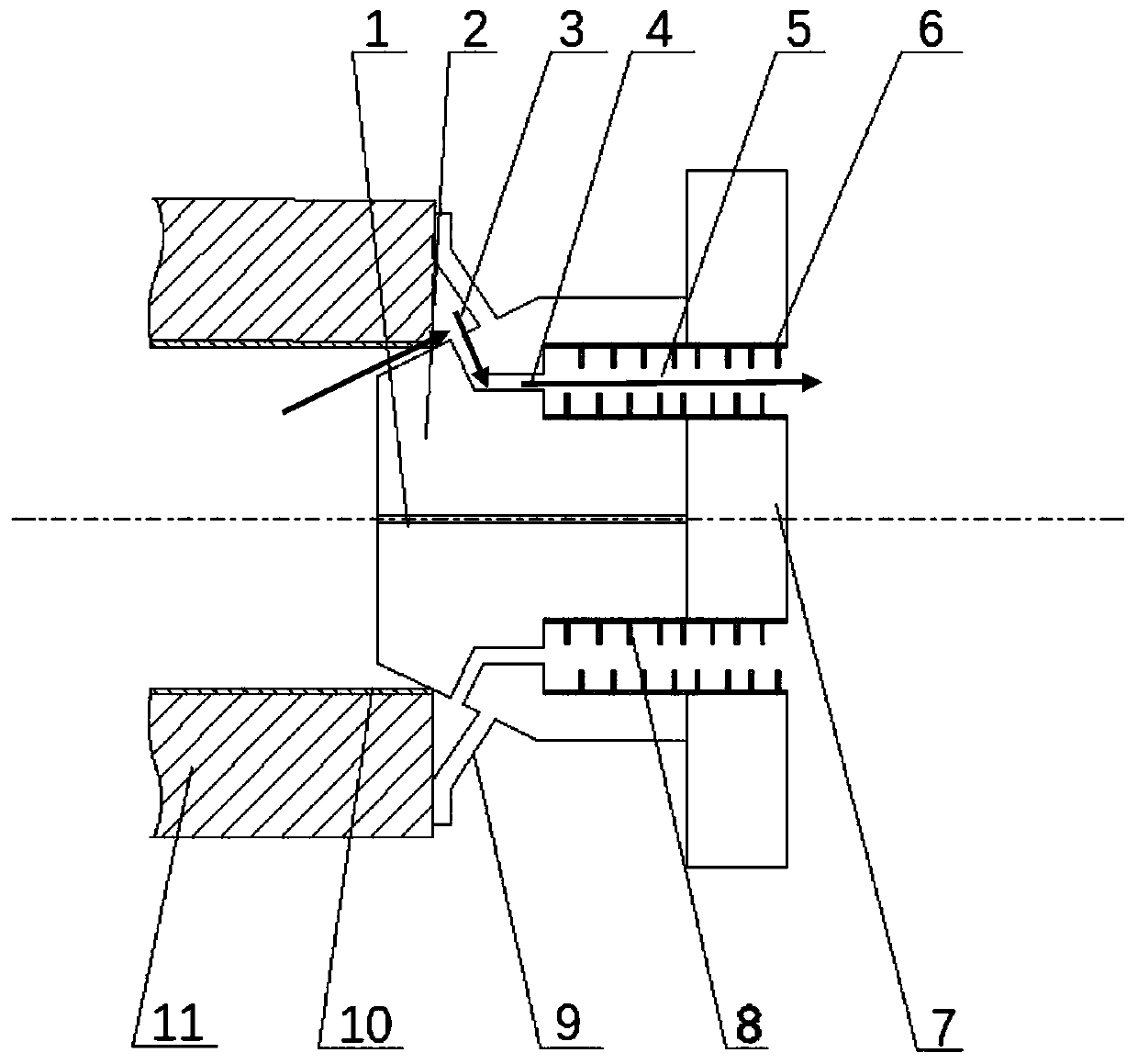

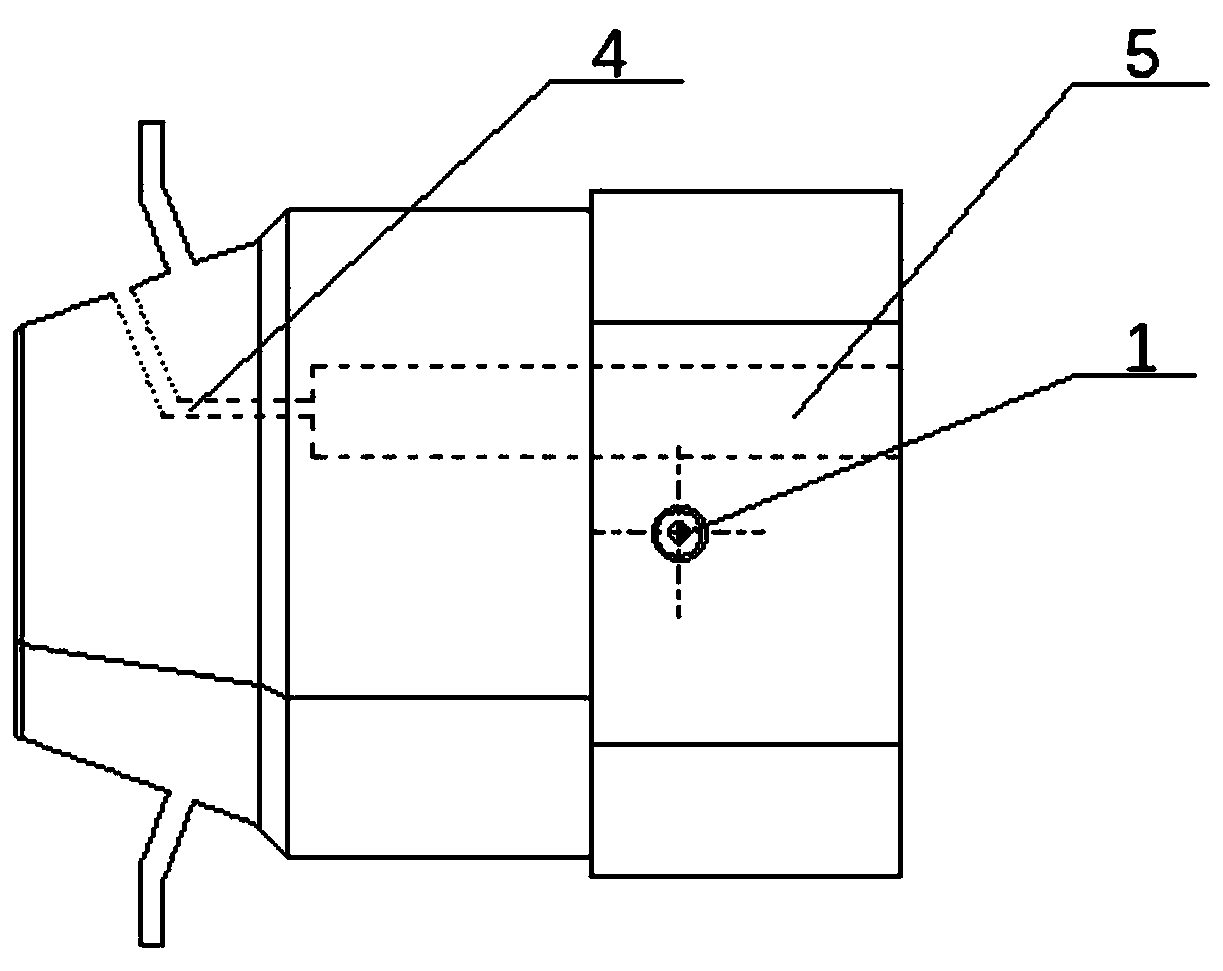

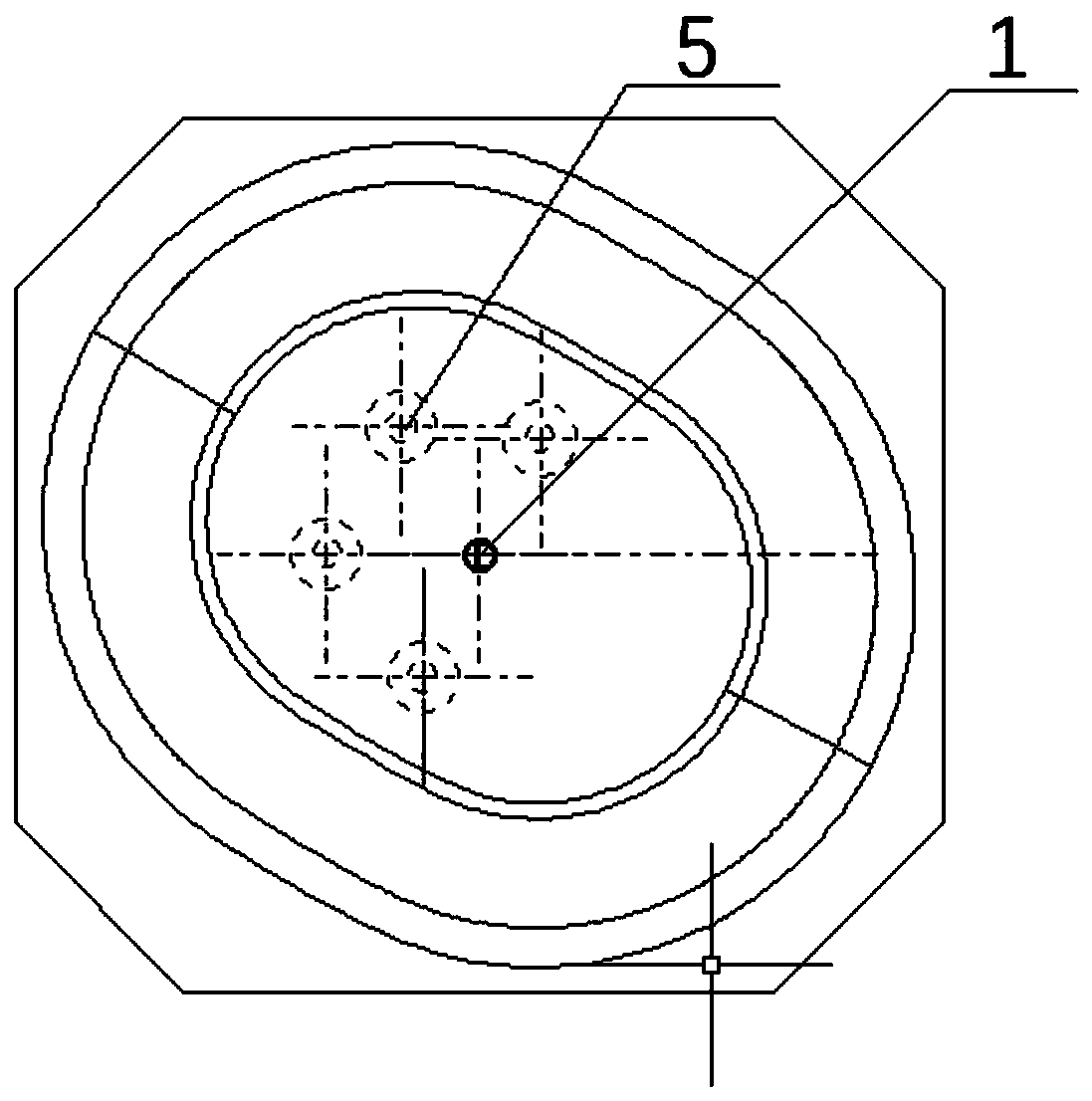

[0027] Example 1: Combining figure 1 , figure 2 and image 3 Description, a punch for hot air pressure forming of metal pipe fittings, including air inlet 1, punch cone 2, air chamber 3, exhaust pipe 4, anechoic chamber 5, two-component silencing cotton 6, flange 7. Silencer disc 8 and baffle plate 9.

[0028] The taper of the punch cone surface 2 is determined according to the diameter of the metal pipe 10. The length of the punch entering the metal pipe is 1 / 3 of the cone surface, and there is a baffle 9 perpendicular to the cone surface at 2 / 3 of the cone surface. In order to strengthen the air chamber To ensure the best sealing effect, the vertical section with a length of 3 cm protruding from the baffle is used to fit the mold.

[0029] An exhaust pipe 4 is arranged between the baffle plate 9 and the position where the punch enters the pipe material. The exhaust pipe 4 is divided into two sections, the first section is perpendicular to the punch cone surface 2, and th...

Embodiment 2

[0030] Embodiment 2: Combination figure 1 and Figure 4 Description It is suitable for local bulging of pipes. The cone surface 2 of the punch is determined according to the diameter of the metal pipe. The length of the punch entering the metal pipe 10 is 1 / 3 of the cone surface. Under the forming condition of no mold forming an air chamber, the baffle 9 is divided into three sections, the first section is a baffle plate perpendicular to the cone surface at 2 / 3 of the cone surface, the second section is parallel to the pipe, and the length is 50mm, and the third section is perpendicular to and in contact with the pipe. The air chamber 3 is formed, and the discharged high-temperature and high-pressure gas is introduced into the exhaust pipe 4 . Such setting increases the application range of the punch for hot air forming of metal pipe fittings.

Embodiment 3

[0031] Example 3: The two-component sound-absorbing cotton 6 of this embodiment is polyester sound-absorbing cotton, and the sound-absorbing cotton 6 and the inner wall of the sound-absorbing chamber are connected by rivets. With such a setting, it has good material stability, will not expand and shrink due to temperature changes, is convenient for maintenance, and has a good noise reduction effect. Others are the same as those in Embodiment 1 or 2.

[0032] Working process: 1: Gas collection: When the conical surface 2 of the sealing punch enters the 1 / 3 position of the metal pipe, the extended section of the baffle plate 9 and the mold 11 form an air chamber. In the case of exhaust, the high-temperature and high-pressure gas is discharged from the matching gap between the metal pipe and the sealing cone surface, enters the air chamber 3, and then enters the exhaust pipe 4.

[0033] 2. Muffling and exporting gas: high-temperature and high-pressure gas enters the muffler cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com