Cylindrical power battery cover plate loading buffer device

A power battery and cover plate technology, which is applied in the field of cylindrical power battery cover material buffering device, can solve the problems of low efficiency of cylindrical power battery cover plate, high number of reciprocating movements, waste of mechanism action, etc., to improve transfer stability, Simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

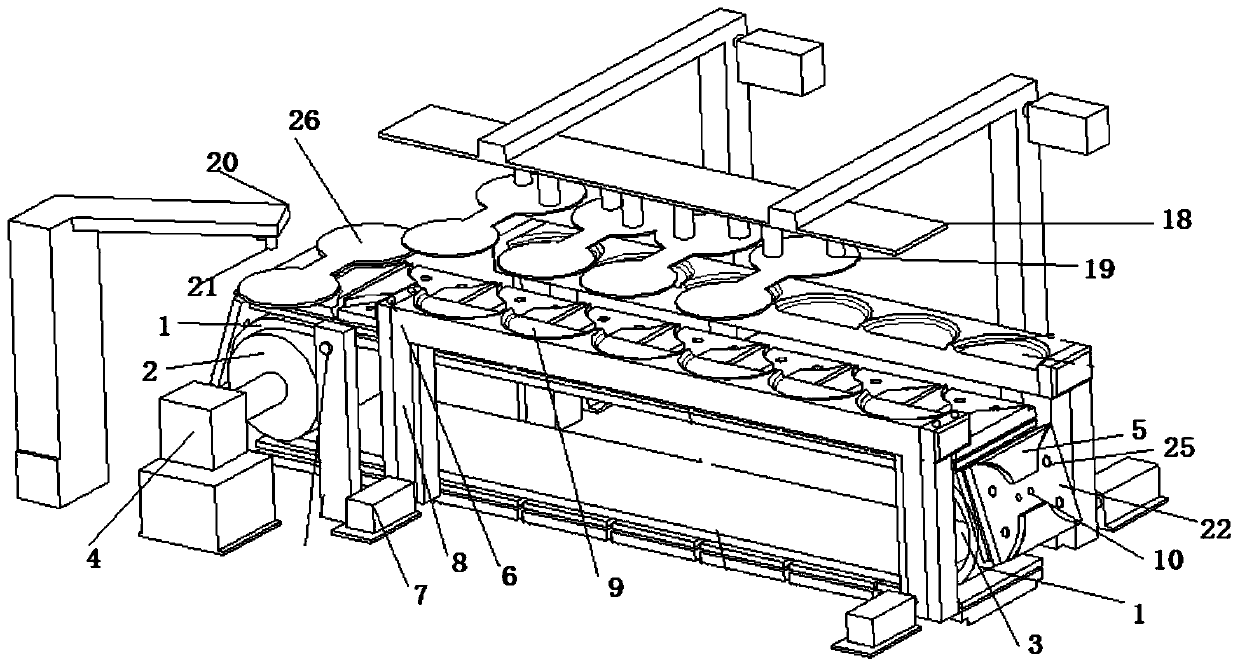

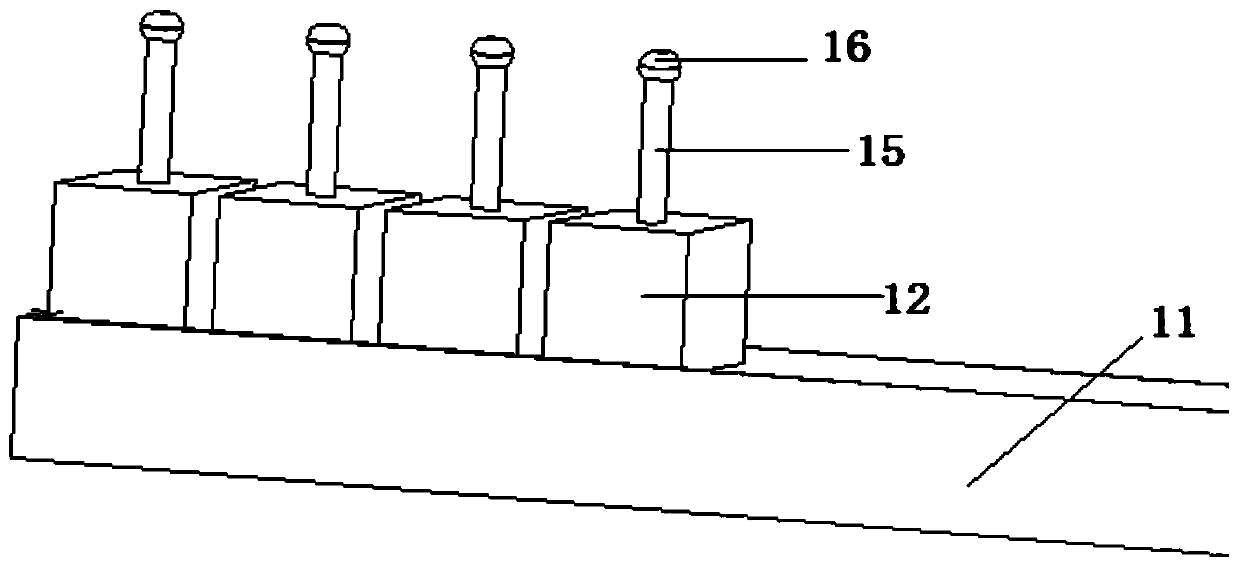

[0023] refer to Figure 1-Figure 4 , the present invention proposes a cylindrical power battery cover material buffer device, including a workbench, a transmission mechanism, a buffer mechanism, a material loading mechanism, a material unloading mechanism and an adsorption mechanism, wherein:

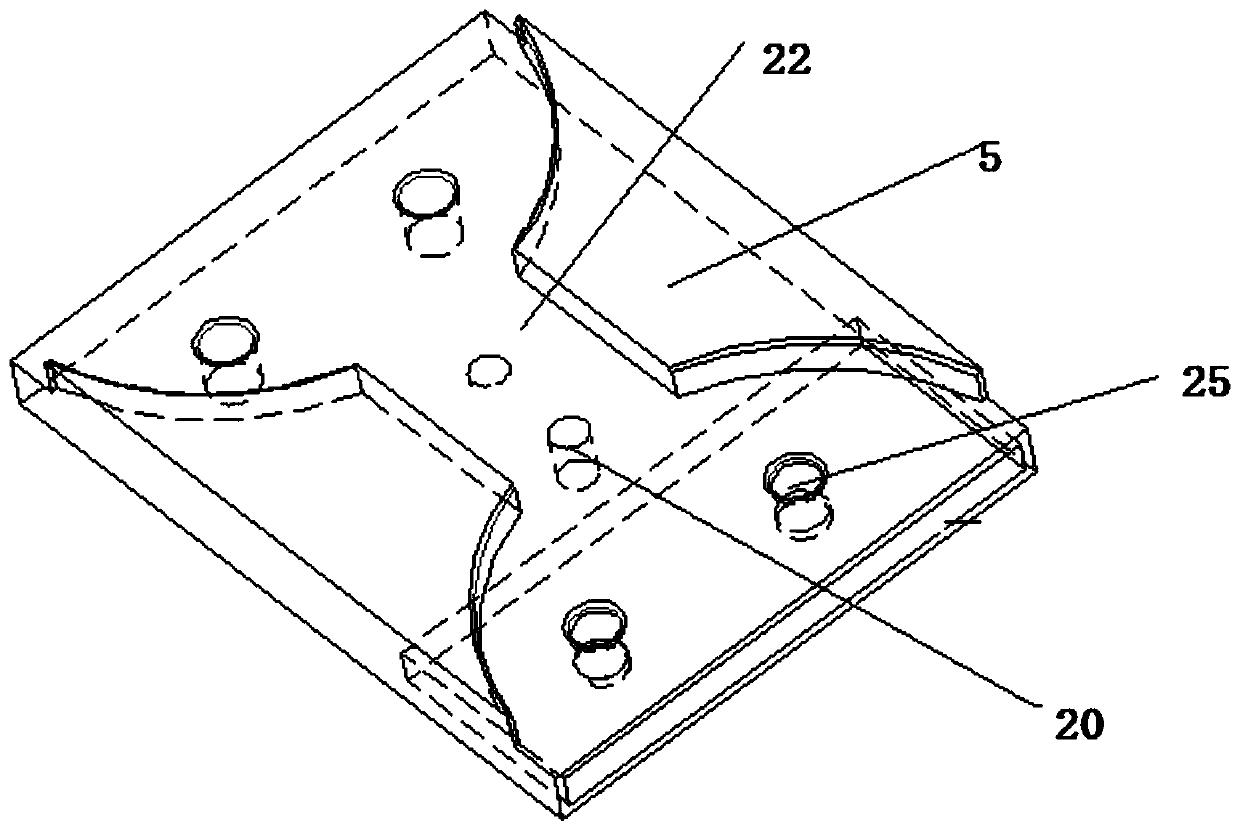

[0024] The conveying mechanism is used for conveying the cover plate, and the conveying mechanism includes a conveying belt 1 , a driving roller 2 , a driven roller 3 and a driving motor 4 . The driving roller 2 and the driven roller 3 are arranged in parallel and opposed to each other, and both ends thereof are installed on the workbench through the mounting frame. The conveyor belt 1 is installed on the outside of the driving roller 2 and the driven roller 3. A plurality of splints 5 for clamping the cover are arranged side by side on the conveyor belt 1. A plurality of assembly holes 25 are arranged on the splint 5, and the splint 5 is installed through the assembly holes 25. On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com