Cooling system of main bearing mechanism of direct drive generator and direct drive generator

A technology of cooling system and main bearing, applied in the direction of engine, wind power generation, wind turbine, etc., can solve problems such as affecting the normal operation of the bearing and large temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

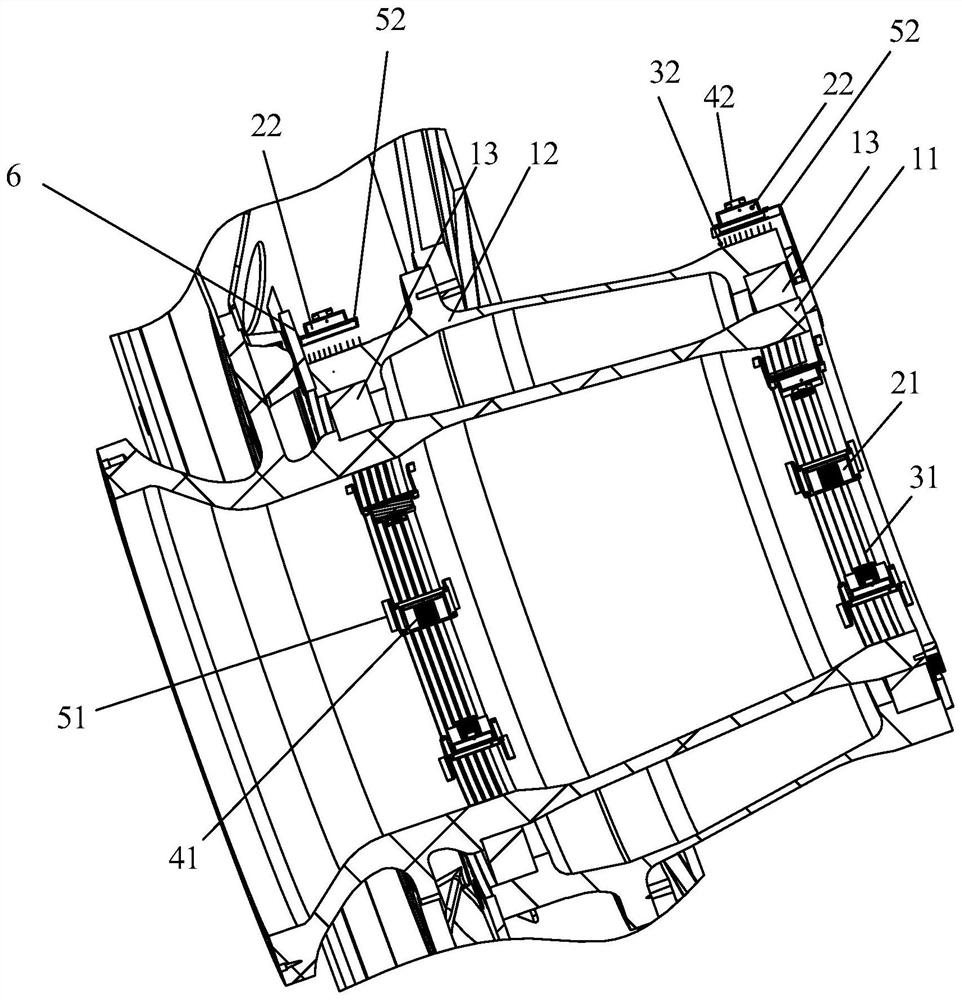

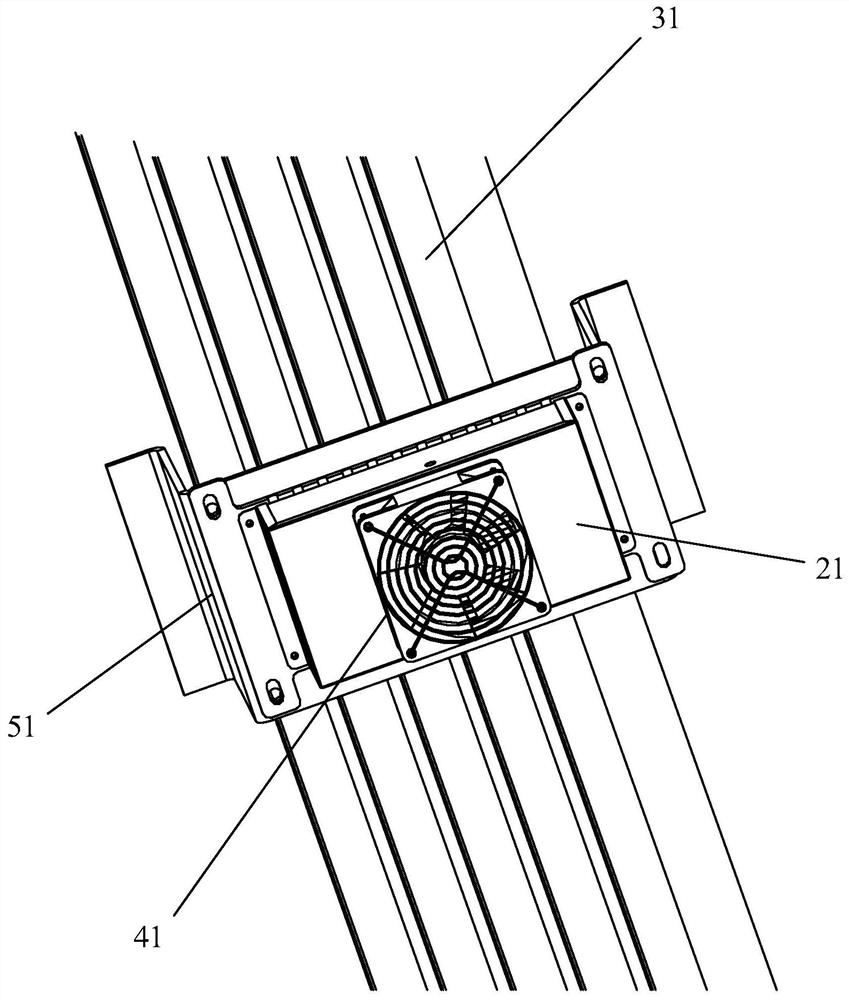

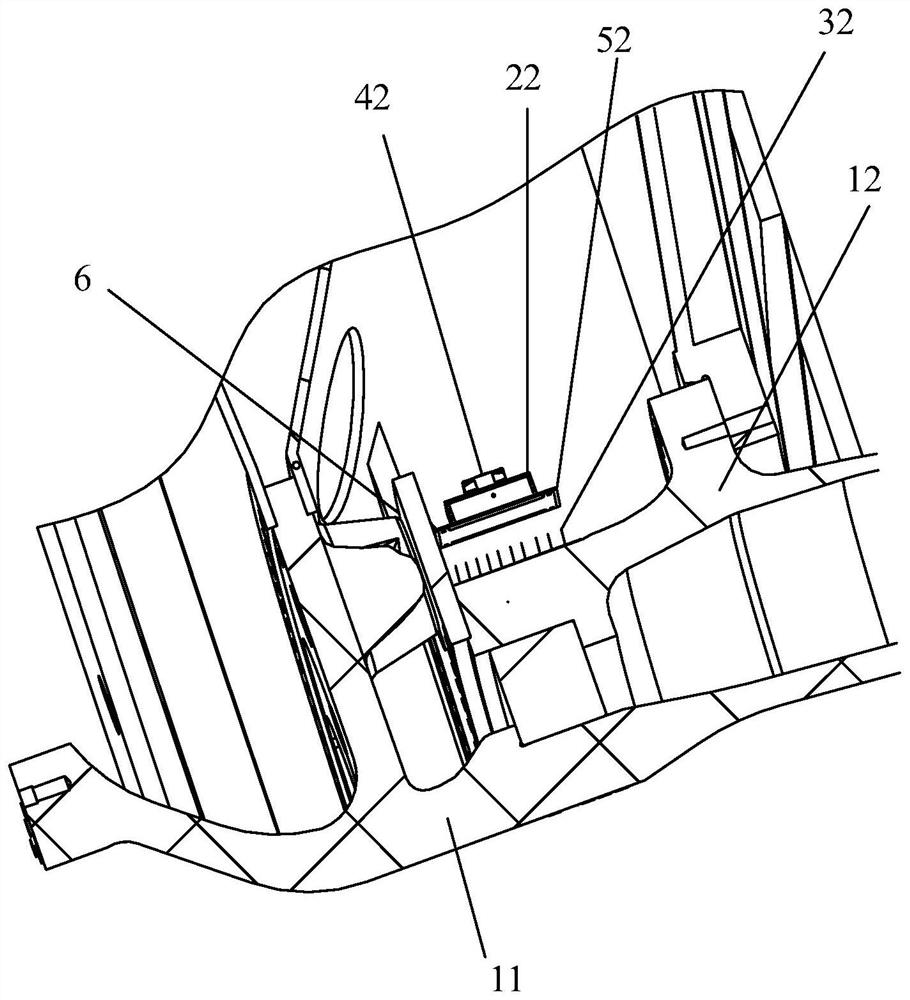

[0043] Such as Figure 1-Figure 7 As shown, this embodiment discloses a cooling system for the main bearing mechanism of the direct drive generator, wherein the cooling system for the main bearing mechanism of the direct drive generator includes the inner shaft 11 of the main bearing, the outer shaft 12 of the main bearing, the bearing 13, the inner Shaft surface radiator 21, outer shaft surface radiator 22, inner shaft surface heat sink 31, outer shaft surface heat sink 32, inner shaft surface fan 41, outer shaft surface fan 42, inner shaft surface support 51, outer shaft surface support 52 , Inner shaft surface support plate 6, generator rotor 7, water pump 81, bypass regulating valve 82, flow regulating valve 83, flow regulating valve 84, flow regulating valve 85, flow regulating valve 86, outboard radiator 87.

[0044] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com