Preparation method of solid-liquid two-phase metal-polymer heat-conducting phase-change composite material

A technology of phase change composite materials and polymer materials, which is applied in the field of preparation of solid-liquid two-phase metal-polymer thermally conductive phase change composite materials, can solve the problem of poor mechanical properties of composite materials, loss of phase change ability, and influence on heat transfer efficiency. and other problems, to achieve the effects of high thermal conductivity, broadening the scope of application, and easy regulation of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

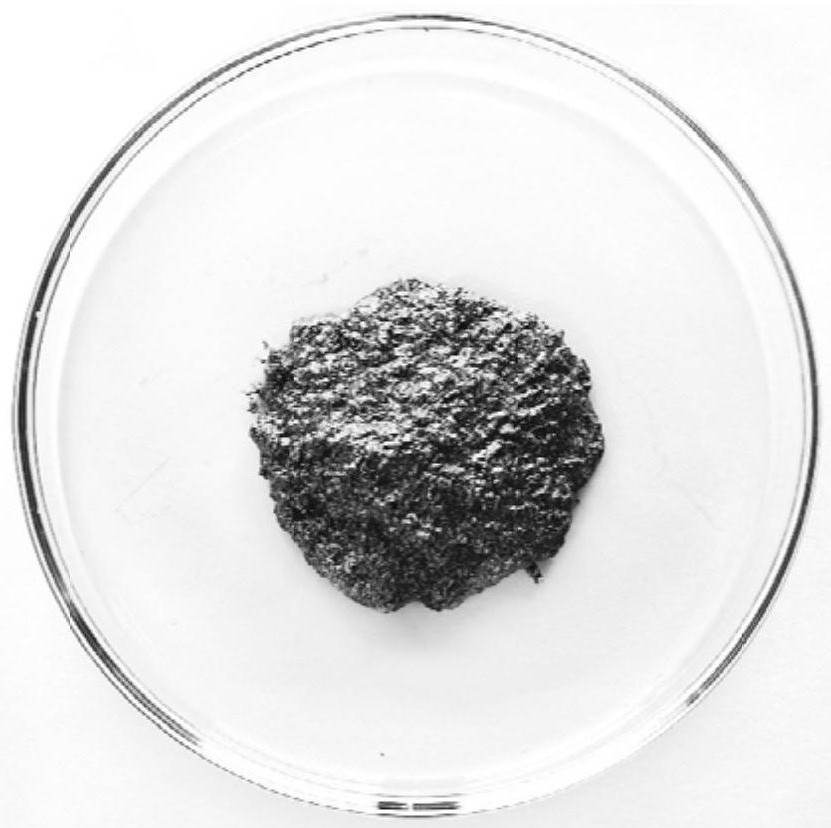

[0033] A method for preparing a solid-liquid two-phase metal-polymer thermally conductive phase-change composite material, comprising the following steps:

[0034] (1) The following components are included in parts by weight: 10 to 90 parts of metals, 1 to 90 parts of polymer materials, and 0 to 50 parts of functional additives; the metals, polymer materials and functional additives are weighed and mixed according to the proportioning ratio, Get the mixed material;

[0035] (2) Heating the mixed material in the range of greater than 10°C and less than 300°C, so that the metal in the solid-liquid coexistence phase and the polymer material in the molten state are physically mixed to obtain a thermally conductive phase-change polymer composite material.

[0036] The physical mixing method is at least one of grinding dispersion, ultrasonic dispersion and mechanical stirring dispersion.

[0037] The ratio of the mass fraction of the solid phase to the liquid phase (solid phase rat...

Embodiment 1

[0062] The invention discloses a method for preparing a metal-polymer thermally conductive phase-change composite material, which comprises the following steps:

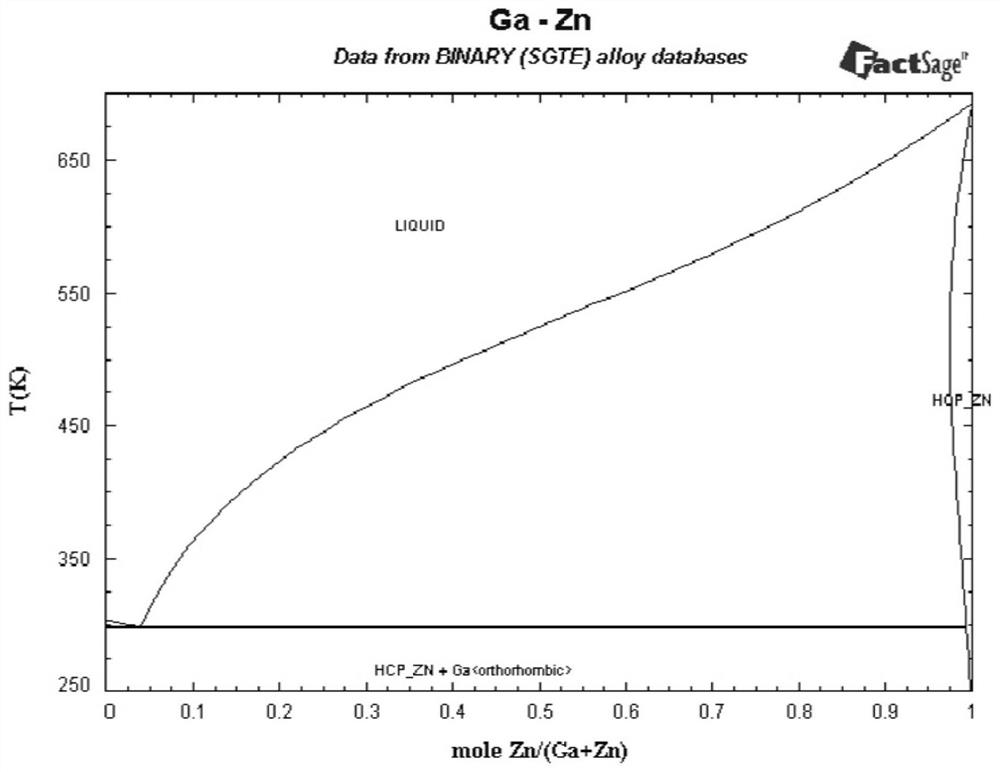

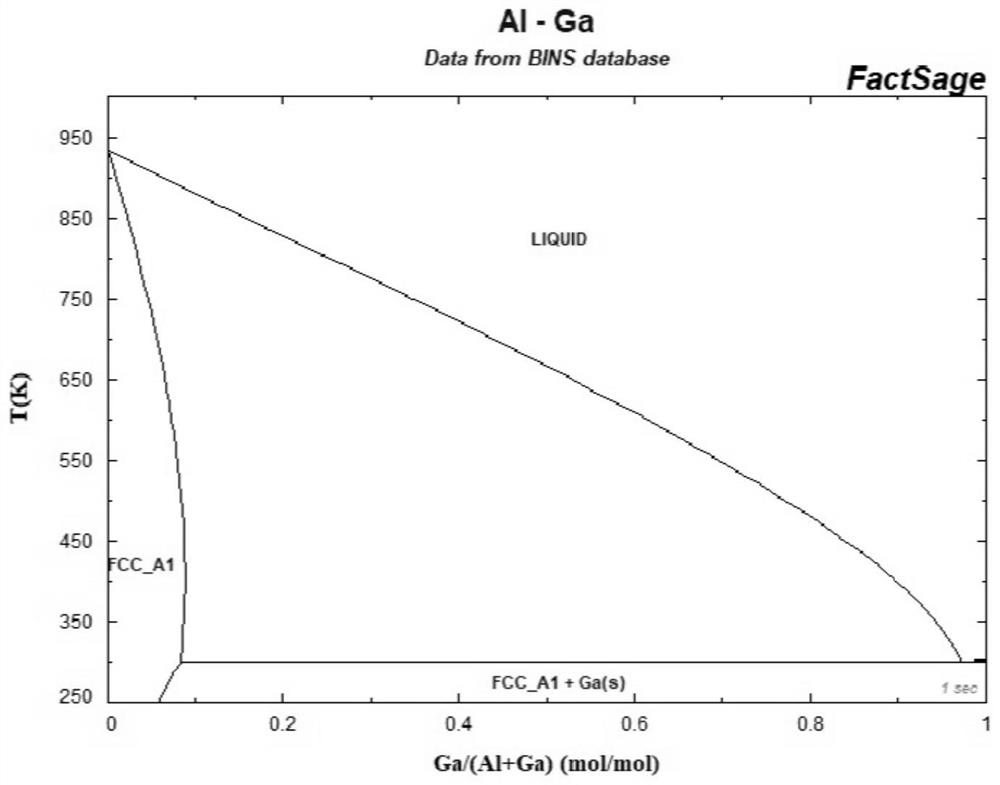

[0063] (1) According to the ratio in Table 1, weigh gallium element, zinc element, methyl silicone oil, anti-sedimentation agent BYK-410, and lauric acid;

[0064] (2) Mix gallium element and zinc element with methyl silicone oil, anti-settling agent BYK-410, and lauric acid;

[0065] (3) Stir the above mixture at 150° C. at a speed of 1500 r / min for 15 minutes by mechanical stirring method and mix well.

Embodiment 2

[0067] The basic steps are the same as in Example 1, and the specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid fraction | aaaaa | aaaaa |

| solid fraction | aaaaa | aaaaa |

| solid fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com