fuel injector

A fuel injector and fuel injection technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of reducing the strength of the nozzle body and reducing the life of the nozzle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

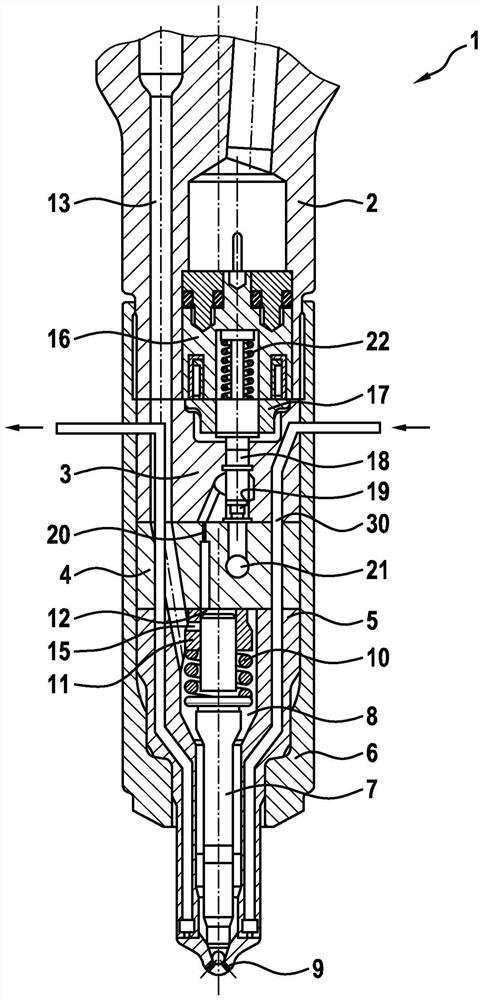

[0029] exist figure 1 A fuel injector 1 , as known from the prior art, for injecting fuel into a combustion chamber of an internal combustion engine is shown in longitudinal section.

[0030] The known fuel injector 1 comprises an injector body 2 , a valve body 3 , an intermediate plate 4 and a nozzle body 5 . All these components are held together by the nozzle clamping nut 6 . In this case, the nozzle body 5 contains a nozzle needle 7 which is arranged longitudinally displaceable in a pressure chamber 8 formed in the nozzle body 5 . During the opening movement of the nozzle needle 7 , fuel is injected into the combustion chamber of the internal combustion engine via a plurality of injection openings 9 formed in the nozzle body 5 .

[0031] A flange can be seen on the nozzle needle 7, on which the compression spring 10 is supported. The other end of the compression spring 10 is supported on a control sleeve 11 , which in turn bears against the underside of the intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com