Automatic textile folding machine

A folding machine and textile technology, applied in the direction of folding thin materials, thin material handling, transportation and packaging, etc., can solve the problems of poor alignment and low folding precision, and achieve good results and high folding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

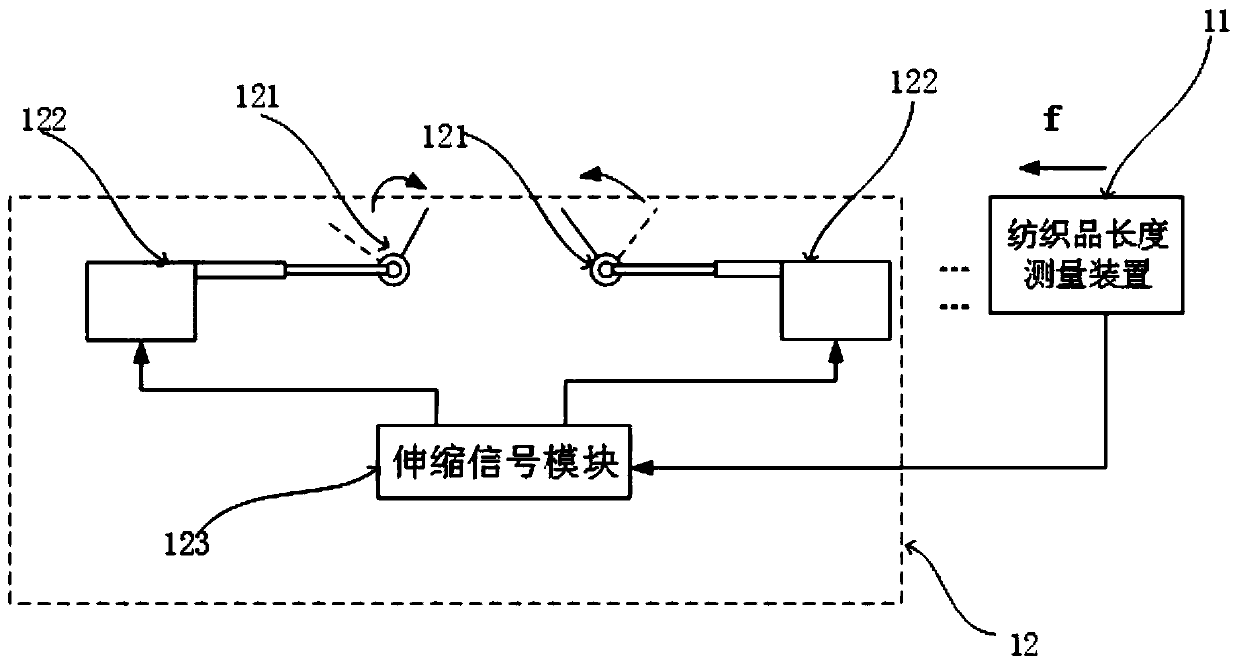

[0061] figure 1 This is a schematic structural diagram of an automatic textile folding machine provided in the embodiment of this specification.

[0062] in figure 1 The folding machine may have: a textile length measuring device 11 and a longitudinal folding device 12;

[0063] f represents the conveying direction of the textile, and the textile length measuring device 11 is located on the feeding side of the longitudinal folding device 12;

[0064] The longitudinal folding device 12 includes a longitudinal folding body, a folding mechanism 121, a telescopic linkage 122 and a telescopic signal module 123;

[0065] The number of the folding mechanism 121 is at least two. The folding mechanism 121 is connected to the longitudinal folding body through a telescopic linkage 122. The textile length measuring device 11 and the telescopic linkage 122 are both electrically connected to the telescopic signal module 123. The telescopic signal module 123 Adjust the distance between at least two ...

Embodiment 2

[0073] The embodiment of this specification adds a positioning sensor on the basis of the first embodiment to sense the transmission of textiles. This is because the position of the textiles is not fixed during transmission on the folding machine. By setting the positioning sensor, the folding speed can be increased at the same time. Increase the folding position to avoid starting to fold the textile before reaching the designated position, thereby improving the folding accuracy.

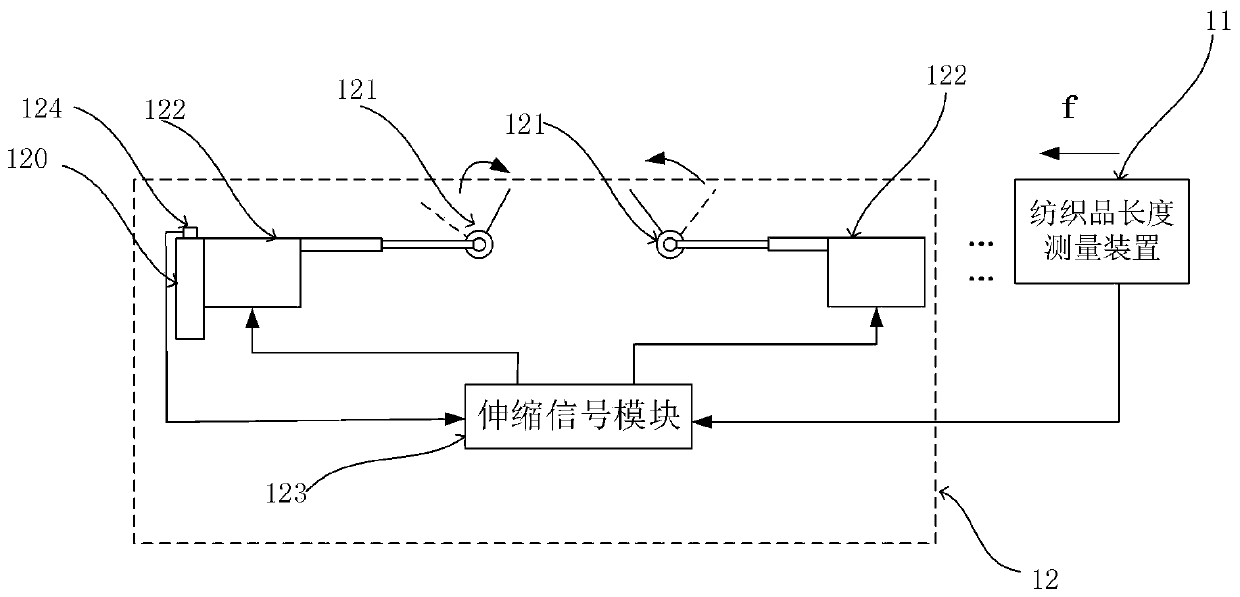

[0074] figure 2 This is a schematic structural diagram of an automatic textile folding machine provided in the embodiment of this specification.

[0075] in figure 2 In the second embodiment, the longitudinal folding body of the folding machine is marked as 120. The longitudinal folding body is the main body of the longitudinal folding device and is used to connect with various mechanisms to support or fix; the longitudinal folding body 120 in the second embodiment is fixed with a positioning sensor 124...

Embodiment 3

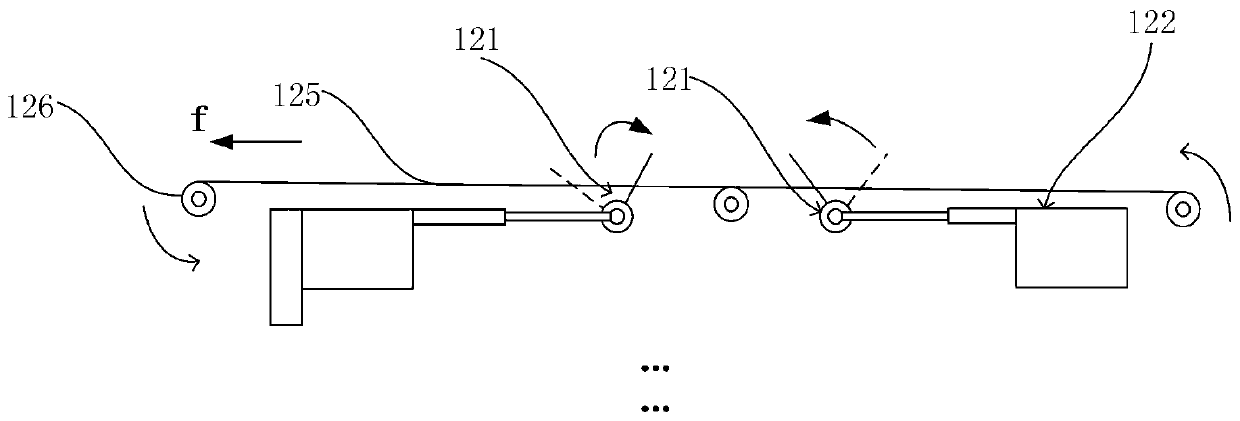

[0077] The third embodiment is to describe the folding mechanism in the first embodiment or the first embodiment, and the folding mechanism may have: a turning shaft, a turning claw, and a turning linkage;

[0078] The turning claw is fixedly connected with the turning shaft;

[0079] The reversing linkage is linked to the reversing shaft;

[0080] The positioning sensor is electrically connected with the flip linkage, and outputs a flip signal to the flip linkage.

[0081] In this way, the electrical signal in the positioning sensor causes the turning shaft to turn in conjunction, so that the turning pawl drives the textile to complete a turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com