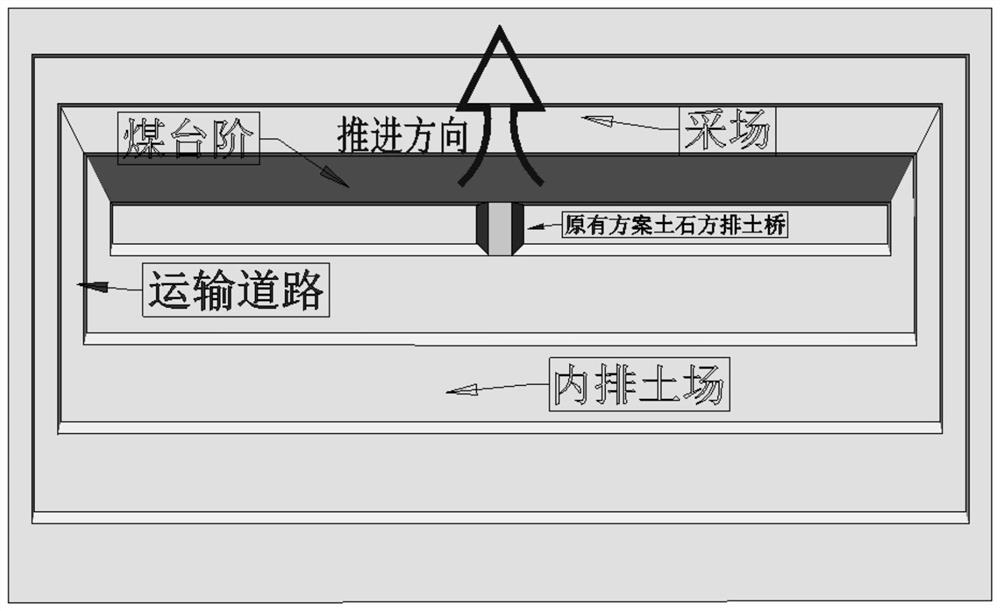

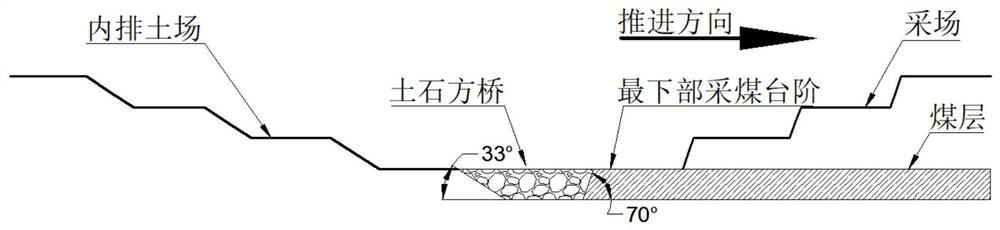

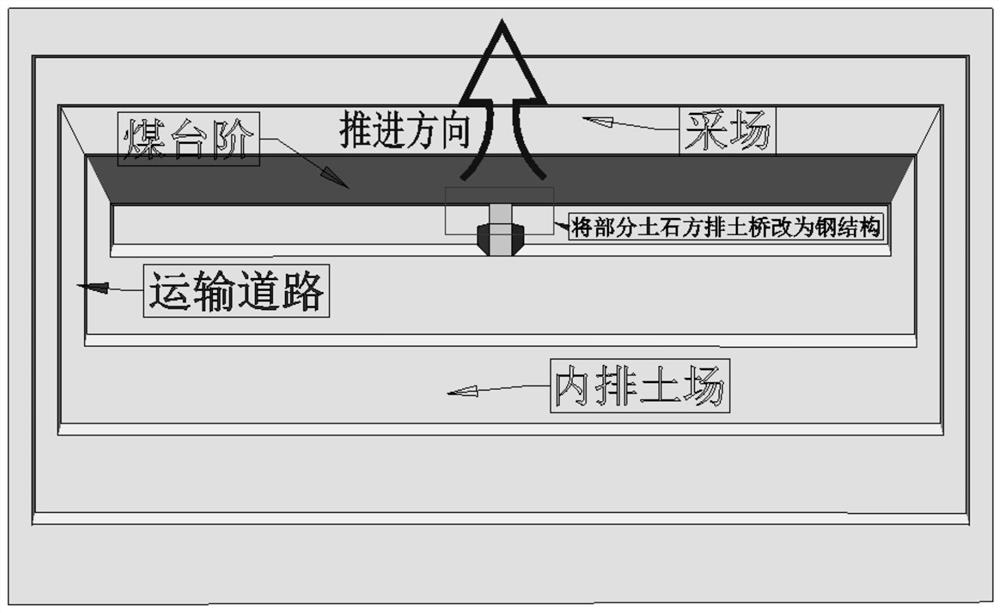

A self-moving driving bridge for connecting the open-pit mine stope and the inner dump

A dumping and self-moving technology, applied in pedestrian bridges, bridges, bridge forms, etc., can solve the problems of increased stripping cost, increased stripping amount, large transportation distance, etc., to save transportation costs, reduce lost time, The effect of saving enterprise investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] like Figure 5 to Figure 10 As shown in the figure, a self-propelled vehicle bridge for connecting the stope and the inner dump of the open-pit mine includes a main bridge deck top plate 1, two main bridge deck side plates 2, a lifting platform 3, and a stope side folding bridge deck 7. The first folded bridge deck 9 on the dump site side and the second folded deck 11 on the dump site side, the left end of the lower surface of the main bridge deck top plate 1 is connected to one end of one of the main bridge deck side plates 2, and the main bridge deck top plate 1. The right end of the lower surface is connected with one end of the other main body bridge deck side plate 2, the front end of the two main body bridge deck side plates 2 is connected with the first side guard plate 4, and the rear end of the two main body bridge deck side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com