Jet grouting pile construction process dynamic monitoring method

A technology of dynamic monitoring and jet grouting piles, which is applied in foundation structure engineering, foundation structure test, construction, etc., can solve problems such as irreparable waste of materials and difficulty in taking remedial measures, and achieve clear and intuitive monitoring results, suitable for popularization Apply, put in nondestructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using the monitoring method introduced by the present invention, a model test is carried out in a certain site, the depth of the jet-jet drilling is 15 meters, and the diameter of the jet-jet pile is 1.5 meters. The specific techniques are as follows:

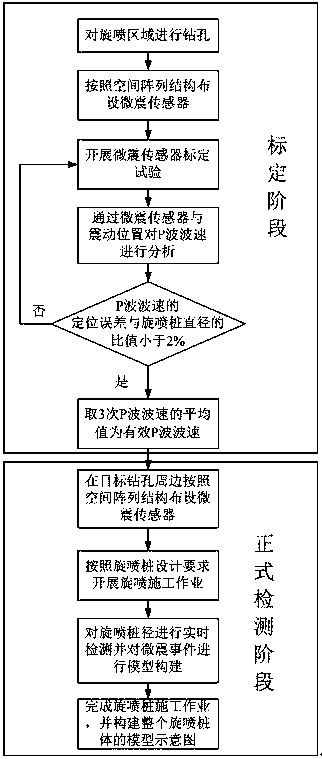

[0034] Such as figure 1 As shown, the dynamic monitoring method of the jet grouting pile construction process is characterized in that the method of dynamically monitoring the size of the pile diameter during the construction process of the jet grouting pile based on the microseismic sensor adopts the following steps:

[0035] Step 1: Drill holes in the rotary grouting area, the diameter of the drilling holes is 130mm, and the drilling distance is 0.8 times the design value of the rotary grouting pile diameter;

[0036] Step 2: After the drilling is completed, arrange 20 microseismic sensors around the target borehole according to the spatial array structure. The horizontal distance between the microseismic sensors and ...

Embodiment 2

[0054] Adopt the monitoring method that the present invention introduces, carry out model test in certain field, and the depth of jet grouting pile is 10 meters, and the diameter of jet grouting pile pile is 1.5 meters, and concrete technology is as follows:

[0055] Such as figure 1 As shown, the dynamic monitoring method of the jet grouting pile construction process is characterized in that the method of dynamically monitoring the size of the pile diameter during the construction process of the jet grouting pile based on the microseismic sensor adopts the following steps:

[0056] Step 1: Drill holes in the jet grouting area, the diameter of the holes is 120mm, and the drilling distance is 0.9 times the design value of the jet grouting pile diameter;

[0057] Step 2: After the drilling is completed, 18 microseismic sensors are arranged around the target borehole according to the spatial array structure, and the horizontal distance between the microseismic sensors and the cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com