A highly compact closed-cycle radial turbine power generation system rotor

A technology of compact closed power generation system, which is applied in hydroelectric power generation, engine components, non-variable pumps, etc., can solve the problems affecting the reliability of the closed cycle turbine power generation system, the rotor connection strength cannot be effectively guaranteed, the connection Part interference reduction and other issues, to achieve high compactness, enhance stability, improve the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

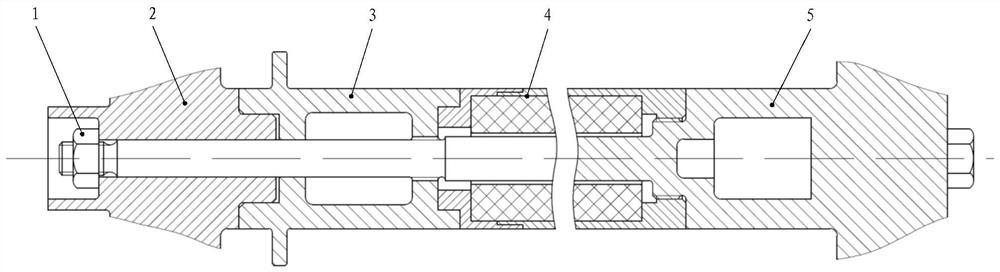

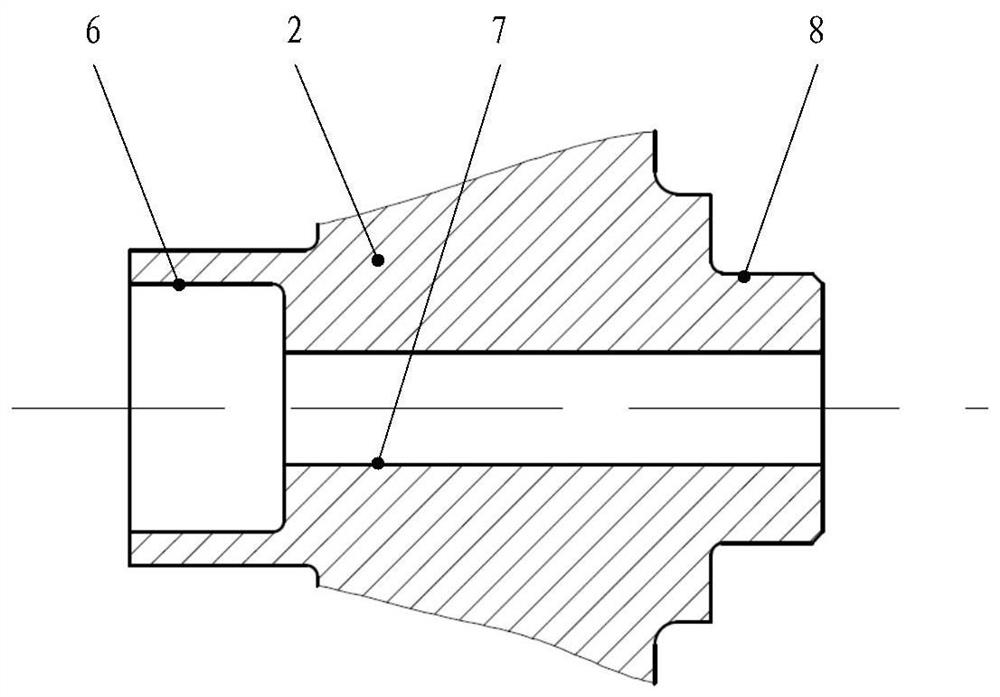

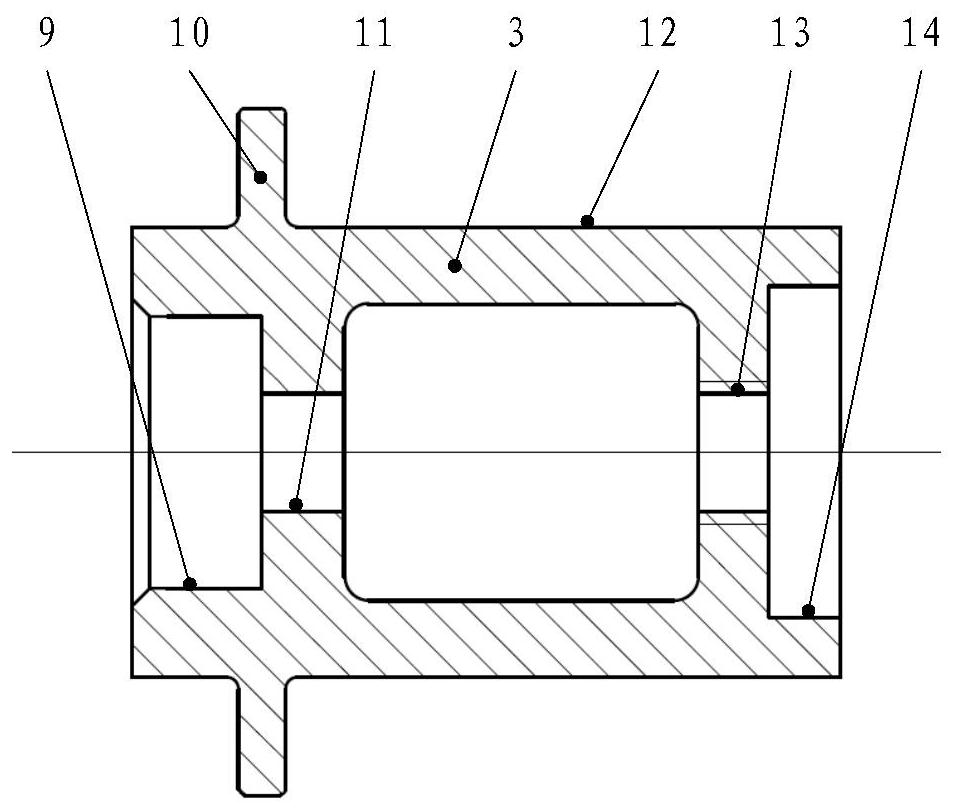

[0027]A rotor structure of a highly compact closed-cycle radial turbine power generation system includes a lock nut 1 , a compressor impeller 2 , a shaft sleeve 3 , a motor shaft 4 and a turbine shaft 5 . The locking nut 1 is assembled on the turbine shaft close to one end of the compressor, and the thread rotation direction of the locking nut 1 is opposite to the rotation direction of the rotor of the turbine power generation system during operation; the compressor impeller 2 is close to the locking nut. One end has an annular protective sleeve 6, the compressor impeller 2 has a central through hole 7, the compressor impeller 2 has an outer cylindrical s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap