Ion wind heat dissipation device and heat dissipation method thereof

A heat sink, ion wind technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., to achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

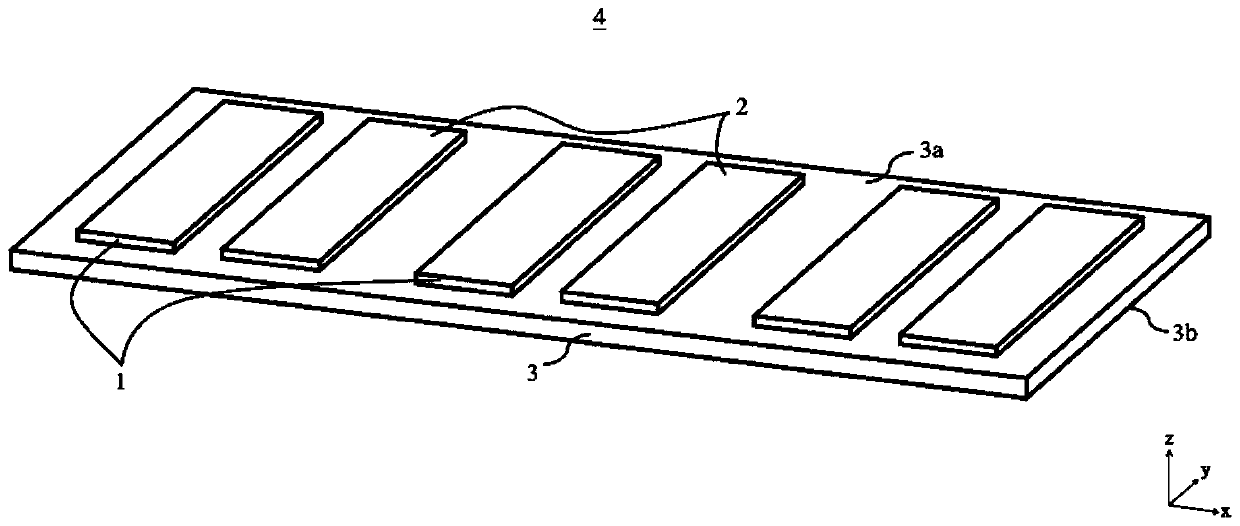

[0060] figure 1 It is a perspective view schematically showing the microstructure type ion wind heat sink 4 according to the first embodiment of the present disclosure.

[0061] The microstructured ionic wind cooling device 4 includes a microstructured ionic wind generating module and a base 3; wherein, the microstructured ionic wind generating module is composed of a number of unipolar microstructured ionic wind generating units.

[0062] The microstructured ion wind generating unit includes a microstructured high voltage electrode 1 and a microstructured ground electrode 2 .

[0063] When the microstructured ion wind cooling device 4 is working, the microstructured high-voltage electrode 1 is powered by a high-voltage power supply, and the microstructured grounding electrode 2 is grounded. A strong electric field will be generated in the area between the microstructured high-voltage electrode 1 and the microstructured grounding electrode 2 . Under the action of a strong ele...

no. 2 Embodiment approach

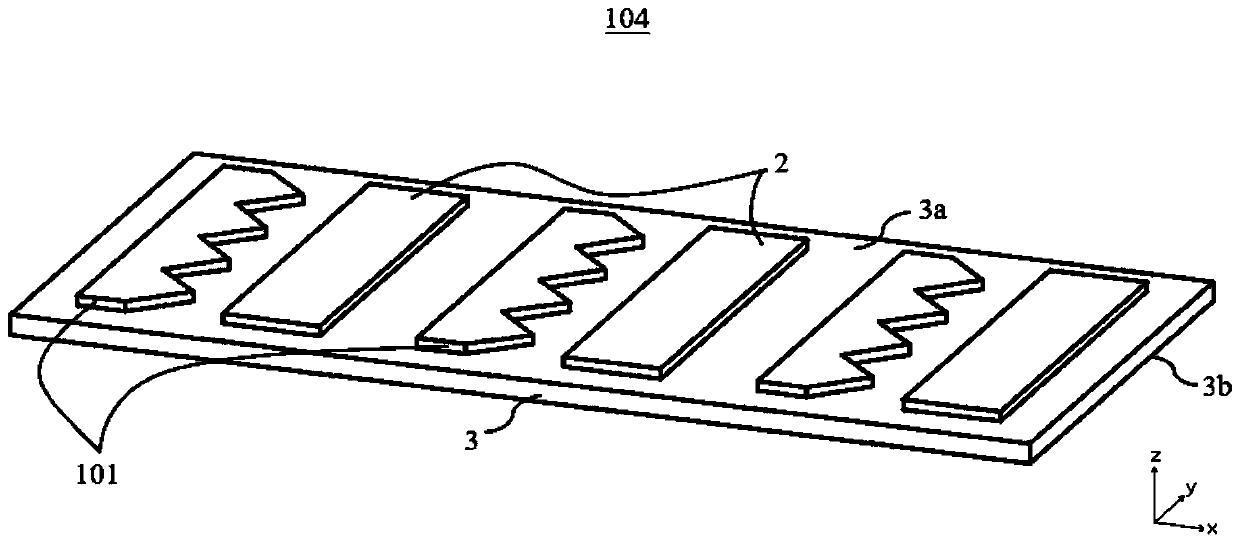

[0075] figure 2 It is a perspective view schematically showing the microstructure type ionic wind heat sink 104 according to the second embodiment of the present disclosure.

[0076] The only difference between the microstructured ionic wind heat sink 104 and the microstructured ionic wind heat sink 4 of the first embodiment lies in the shape of the microstructured high voltage electrodes. Specifically, as follows.

[0077] The microstructured high voltage electrode 101 is configured in a shape in which the distance from the microstructured ground electrode 2 varies. For example, the planar shape of the microstructure high-voltage electrode 101 near the downstream side of the ion wind is zigzag, so the electrode spacing of the microstructure ion wind generating unit changes along the width direction (y direction).

[0078] In addition, the size and number of the sawtooth structures of the microstructure high voltage electrode 101 can be properly adjusted according to heat d...

no. 3 Embodiment approach

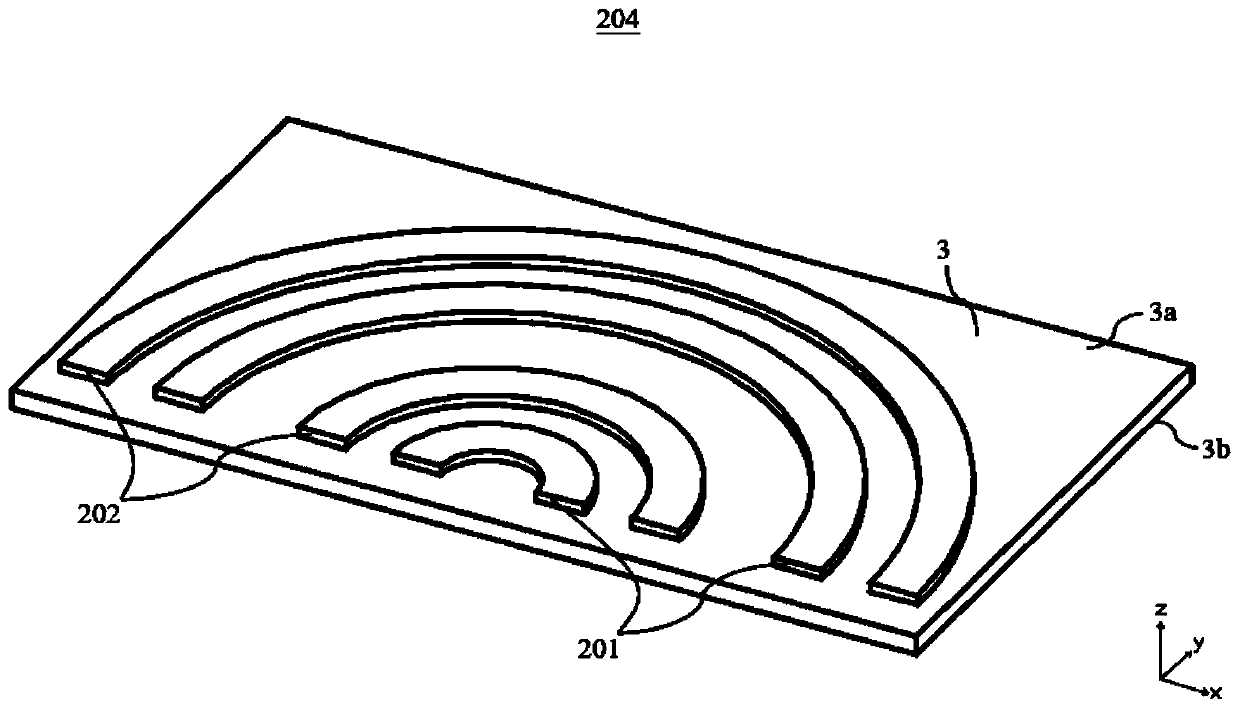

[0082] image 3 It is a perspective view schematically showing the microstructure type ionic wind heat sink 204 according to the third embodiment of the present disclosure.

[0083] The only difference between the microstructured ionic wind heat sink 204 and the microstructured ionic wind heat sink 4 of the first embodiment lies in the shape of the microstructured high voltage electrode and the microstructured ground electrode. Specifically, as follows.

[0084] The plane shapes of the microstructure high voltage electrode 201 and the microstructure ground electrode 202 are arched. In addition, the width of these electrodes in the radial direction can either remain the same or vary along the circumferential direction.

[0085] In addition, the width of the microstructure high voltage electrode 201 and the microstructure ground electrode 202 in the radial direction and the circumferential angle of the electrodes can be properly adjusted according to the size of the space and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com