Cooking utensil with pressure control structure

A technology for cooking utensils and containers, which is applied to cooking utensils, pressure cookers, household utensils, etc., and can solve problems such as unsatisfactory heating uniformity of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

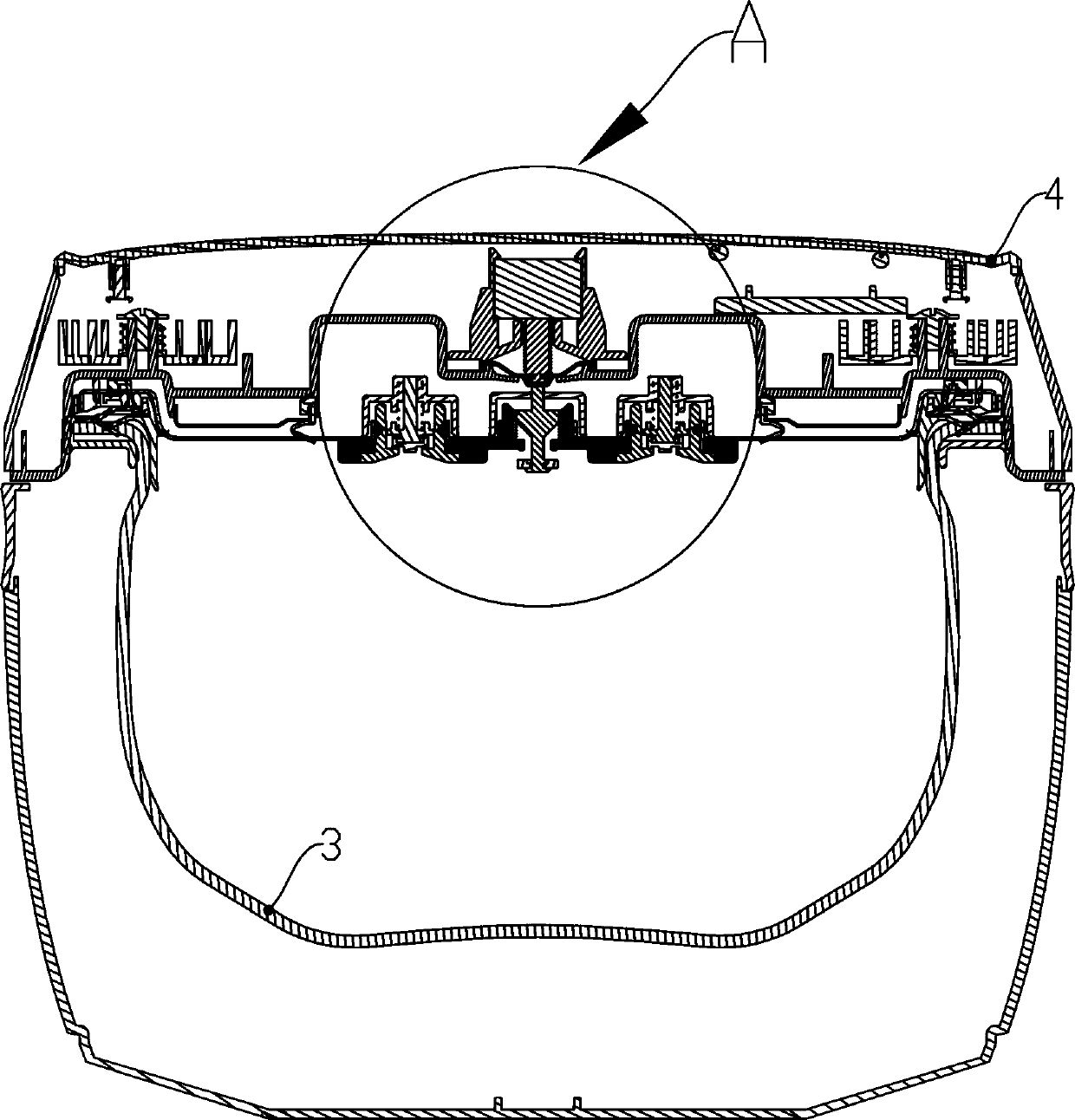

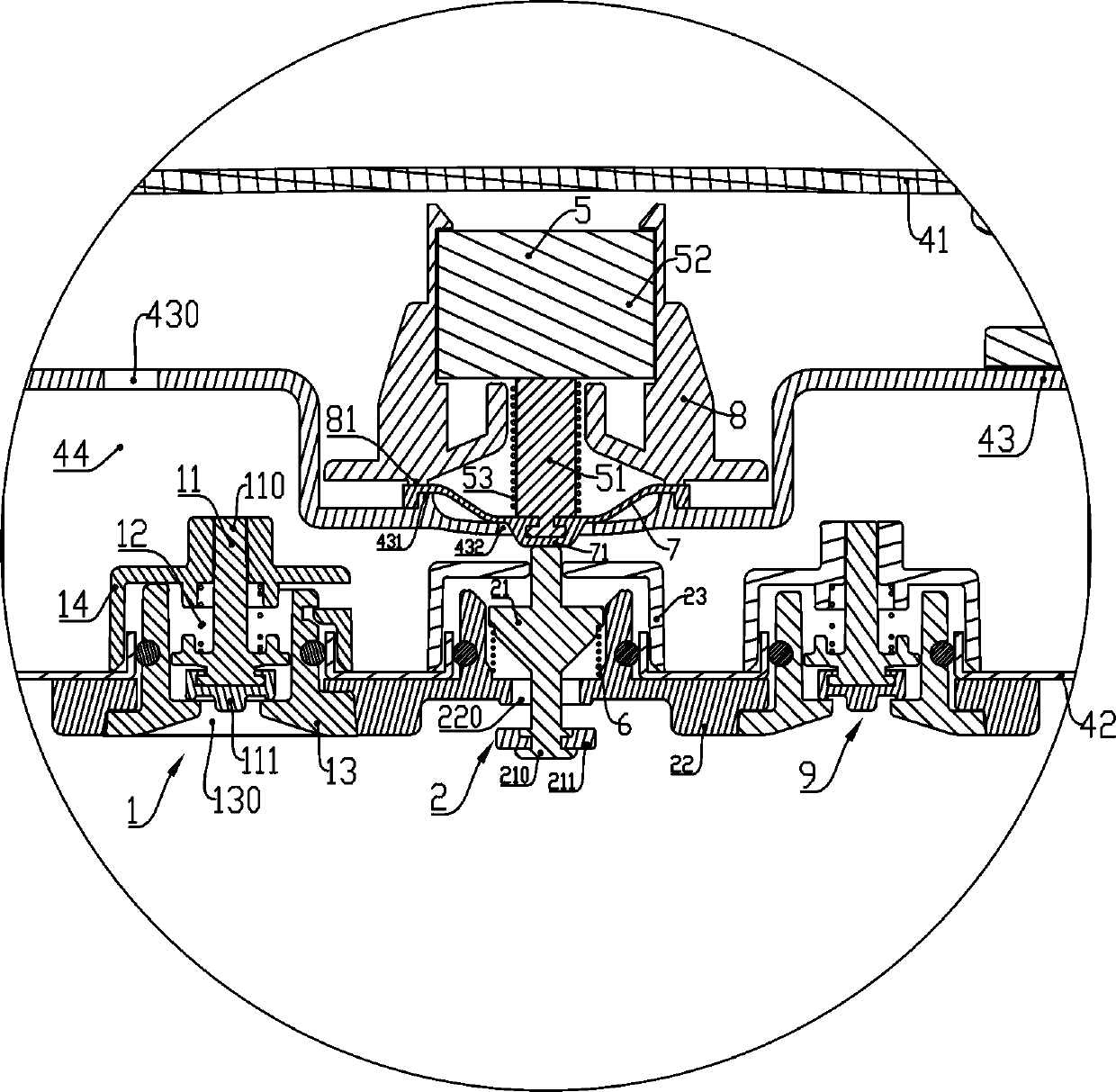

[0020] The structure of a cooking appliance with a pressure control structure applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 with figure 2 As shown, a cooking appliance with a pressure control structure includes a container 3 for holding food and a cover 4 covered on the container 3. A first pressure relief valve 1 and a second pressure relief valve 2 are provided on the cover body 4. The first pressure relief valve 1 is used to maintain the working internal pressure in the container 3 in a high-pressure environment. The first pressure relief valve 1 is arranged so that when the working internal pressure in the container 3 is higher than the pressure threshold P 0 Acts and releases the gas in the container 3 to the external space so that the high-pressure working environment is maintained in the container 3, and the pressure threshold is higher than the atmospheric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com