Flame cutting machine convenient for clamping of steel plates with different thicknesses

A flame cutting machine, steel plate technology, applied in the direction of gas flame welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of waste, steel plate offset, time-consuming and labor-intensive, etc., to achieve waste avoidance, reasonable structural design, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment:

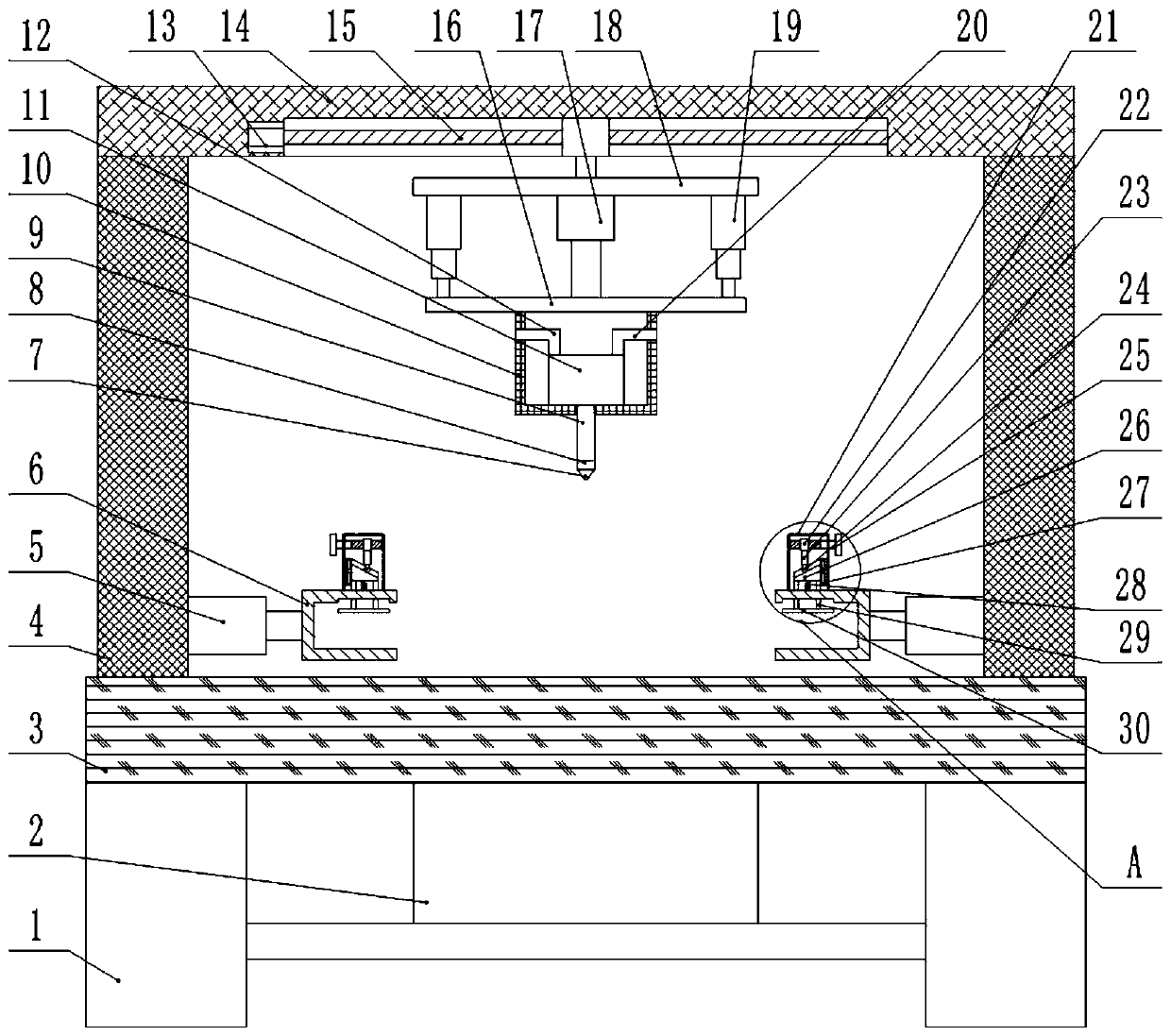

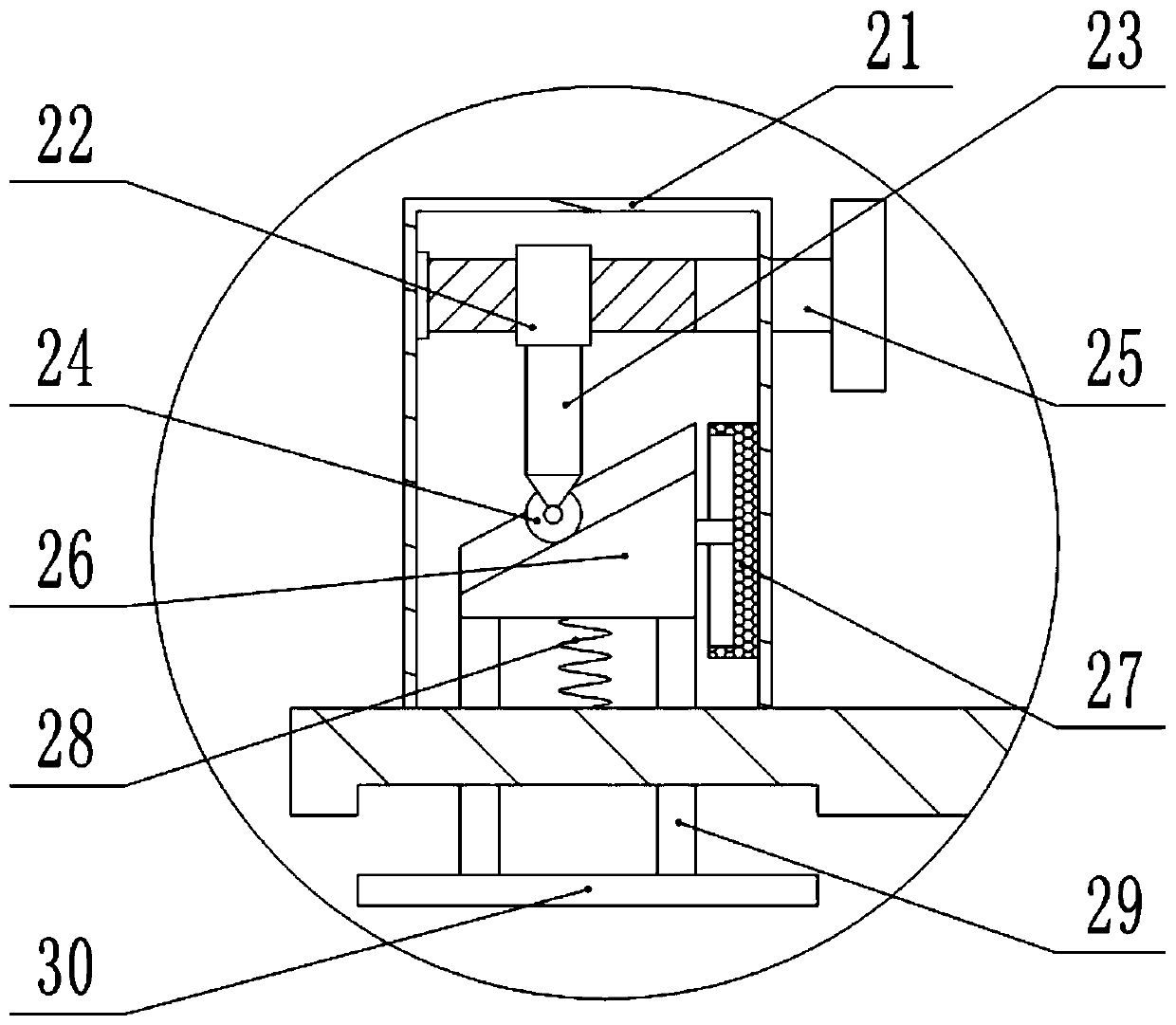

[0016] A flame cutting machine for clamping steel plates of different thicknesses, comprising a workbench 3, characterized in that the bottom of the workbench 3 is fixed with a number of vertical support feet 1, and the two ends of the workbench 3 correspond to A vertical column 4 is installed, and the top of the column 4 is horizontally fixed with the same top plate 14, and the bottom of the top plate 14 is provided with a horizontal groove structure with an opening downward, and a horizontal groove structure is provided in the horizontal groove structure. Lead screw 15, one end of said lead screw 15 is rotatably installed on the end wall of said horizontal groove structure, and the other end of said lead screw 15 is coaxially provided with forward and reverse motor 13, and said forward and reverse motor 13 Installed on the lower part of the top plate 14, the screw 15 is covered wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com