Spiral supporting spring assembling mechanism

A technology of spiral support springs and assembly mechanisms, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low assembly efficiency and unstable production quality, reduce labor costs, realize automatic assembly, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are presented to illustrate certain embodiments of the invention and should not be construed as limiting the scope of the invention. The content disclosed in the present invention can be improved simultaneously from materials, methods and reaction conditions, and all these improvements should fall within the spirit and scope of the present invention.

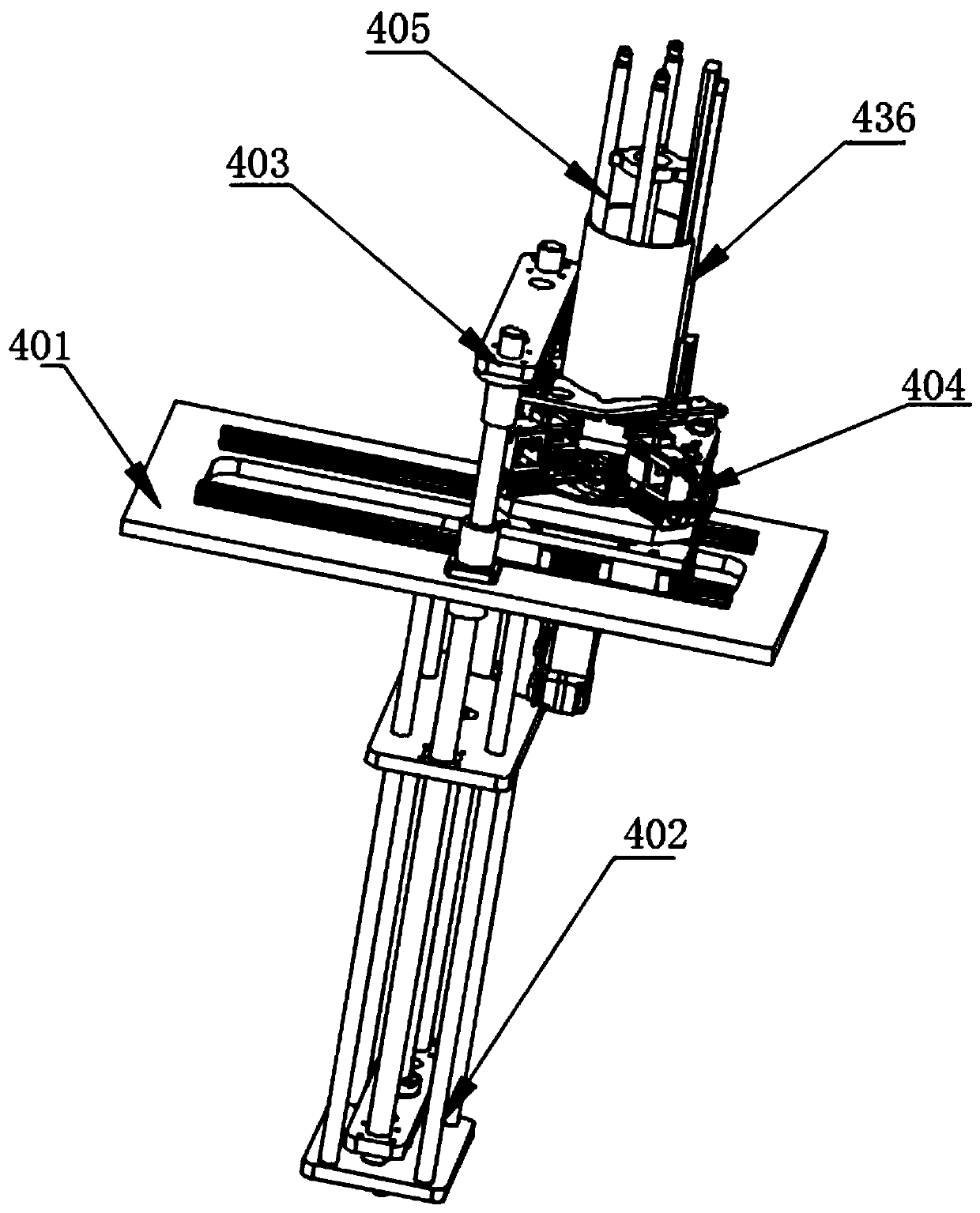

[0020] like Figure 1-6 As shown, a spiral spring assembly mechanism includes a mechanism installation base plate 401 fixed on the console. A push coil spring mechanism 403 connected to the support structure 402 of the push coil spring mechanism is provided, and one side of the push coil spring mechanism 403 is provided with a tension coil spring mechanism 404 slidingly connected to the mechanism installation base plate 401, and the The upper part of the stretching spiral spring mechanism 404 is provided with a spiral spring barrel 405 .

[0021] In this embodiment, the support structure 402 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com