Polyurethane rubber plate conveying device capable of realizing automatic compensation after abrasion

A polyurethane rubber sheet, automatic compensation technology, used in transportation and packaging, winding strips, thin material processing, etc., can solve the problems of loss of use function, low size utilization, deviation from the original size, etc., to improve service life, Improve the product size utilization rate and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

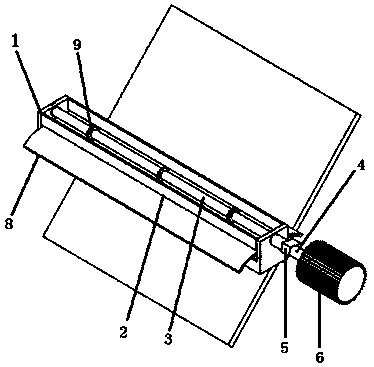

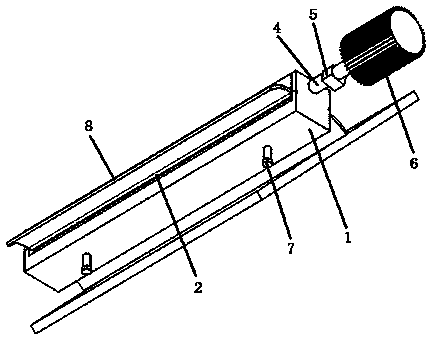

[0010] Embodiment 1: see figure 1 , figure 2 Now, a polyurethane rubber sheet conveying device that can realize automatic compensation after wear and tear provided by the present invention will be described. The inner cavity of the strip-shaped hollow frame body 1 is provided with a feeding drive shaft 3 along its length direction, and an automatic compensation mechanism is provided on the outer end wall of one side of the strip-shaped hollow frame body 1 in the length direction. The automatic compensation mechanism includes a shaft coupling 4, a torque sensor 5, and a motor 6, and the bottom ends of the strip-shaped hollow frame body 1 in the length direction are respectively provided with screw holes, and compression bolts are respectively screwed into the screw holes. 7.

Embodiment 2

[0011] Example 2: see figure 1 , figure 2 Now, a polyurethane rubber plate conveying device that can realize automatic compensation after wear and tear provided by the present invention is described. The inner cavity of the strip-shaped hollow frame body 1 is inserted with a polyurethane rubber plate 8 through the strip-shaped opening 2. The upper end panel of the strip-shaped hollow frame body 1 is designed to be detachable, and the end of the side end of the feeding drive shaft 3 corresponding to the position of the automatic compensation mechanism protrudes through the inner end wall of the strip-shaped hollow frame body 1. The torque sensor 5 is connected between the protruding end of the feeding drive shaft 3 and the output shaft of the motor 6 through a coupling 4 , and gears 9 are equidistantly arranged on the feeding drive shaft 3 .

[0012] The present invention can also combine at least one of the technical features described in Embodiment 2 with Embodiment 1 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com