Method of preparing high purity thulium, high purity ytterbium and high purity lutecium

A technology of thulium, ytterbium, lutetium and ytterbium chloride, applied in the direction of improving process efficiency, etc., can solve the problem that the product purity does not reach 5N level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The C272 organic phase is a sulfonated kerosene solution of the extractant C272, wherein the volume percentage of C272 is 30%, the volume percentage of isooctyl alcohol is 10%, and the volume percentage of the sulfonated kerosene solution is 60%. When used, a general saponification method must be adopted to obtain the corresponding rare earth saponified organic phase after corresponding saponification.

[0025] The composition of the rare earth chloride aqueous solution of thulium, ytterbium and lutetium enrichment is: Er 0.000080g / L, Tm 18.0g / L, Yb120.0g / L, Lu 26.0g / L.

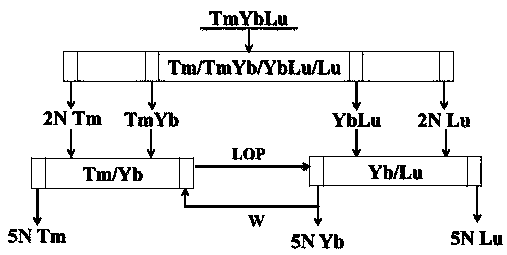

[0026] 1) Tm / TmYb / YbLu / Lu four-outlet fractional distillation extraction separation system

[0027] The 2N thulium saponification C272 organic phase is used as the extraction organic phase, the rare earth chloride aqueous solution of the thulium, ytterbium and lutetium enrichment is used as the feed solution, and 3.0mol / L HCl is used as the washing acid. The 2N thulium saponification C272 organic phas...

Embodiment 2

[0036] The C272 organic phase is a sulfonated kerosene solution of the extractant C272, wherein the volume percentage of C272 is 30%, the volume percentage of isooctyl alcohol is 10%, and the volume percentage of the sulfonated kerosene solution is 60%. When used, a general saponification method must be adopted to obtain the corresponding rare earth saponified organic phase after corresponding saponification.

[0037] The composition of the rare earth chloride aqueous solution of thulium, ytterbium and lutetium enrichment is: Er 0.000050g / L, Tm 20.0g / L, Yb125.0g / L, Lu 23.0g / L.

[0038] 1) Tm / TmYb / YbLu / Lu four-outlet fractional distillation extraction separation system

[0039] The 2N thulium saponification C272 organic phase is used as the extraction organic phase, the rare earth chloride aqueous solution of the thulium, ytterbium and lutetium enrichment is used as the feed solution, and 3.0mol / L HCl is used as the washing acid. The 2N thulium saponification C272 organic phas...

Embodiment 3

[0048] The C272 organic phase is a sulfonated kerosene solution of the extractant C272, wherein the volume percentage of C272 is 30%, the volume percentage of isooctyl alcohol is 10%, and the volume percentage of the sulfonated kerosene solution is 60%. When used, a general saponification method must be adopted to obtain the corresponding rare earth saponified organic phase after corresponding saponification.

[0049] The composition of the rare earth chloride aqueous solution of thulium, ytterbium and lutetium enrichment is: Er 0.000010g / L, Tm 22.0g / L, Yb130.0g / L, Lu 20.0g / L.

[0050] 1) Tm / TmYb / YbLu / Lu four-outlet fractional distillation extraction separation system

[0051] The 2N thulium saponification C272 organic phase is used as the extraction organic phase, the rare earth chloride aqueous solution of the thulium, ytterbium and lutetium enrichment is used as the feed solution, and 3.0mol / L HCl is used as the washing acid. The 2N thulium saponification C272 organic phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com