Perspiration absorption and breathable textile fabric and production technology thereof

A textile fabric and breathable technology, applied in the field of textile fabrics, can solve the problems of single fabric performance, unsatisfactory effect of breathability and sweat absorption, etc., and achieve the effects of good sweat absorption and breathability, good sunscreen effect and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

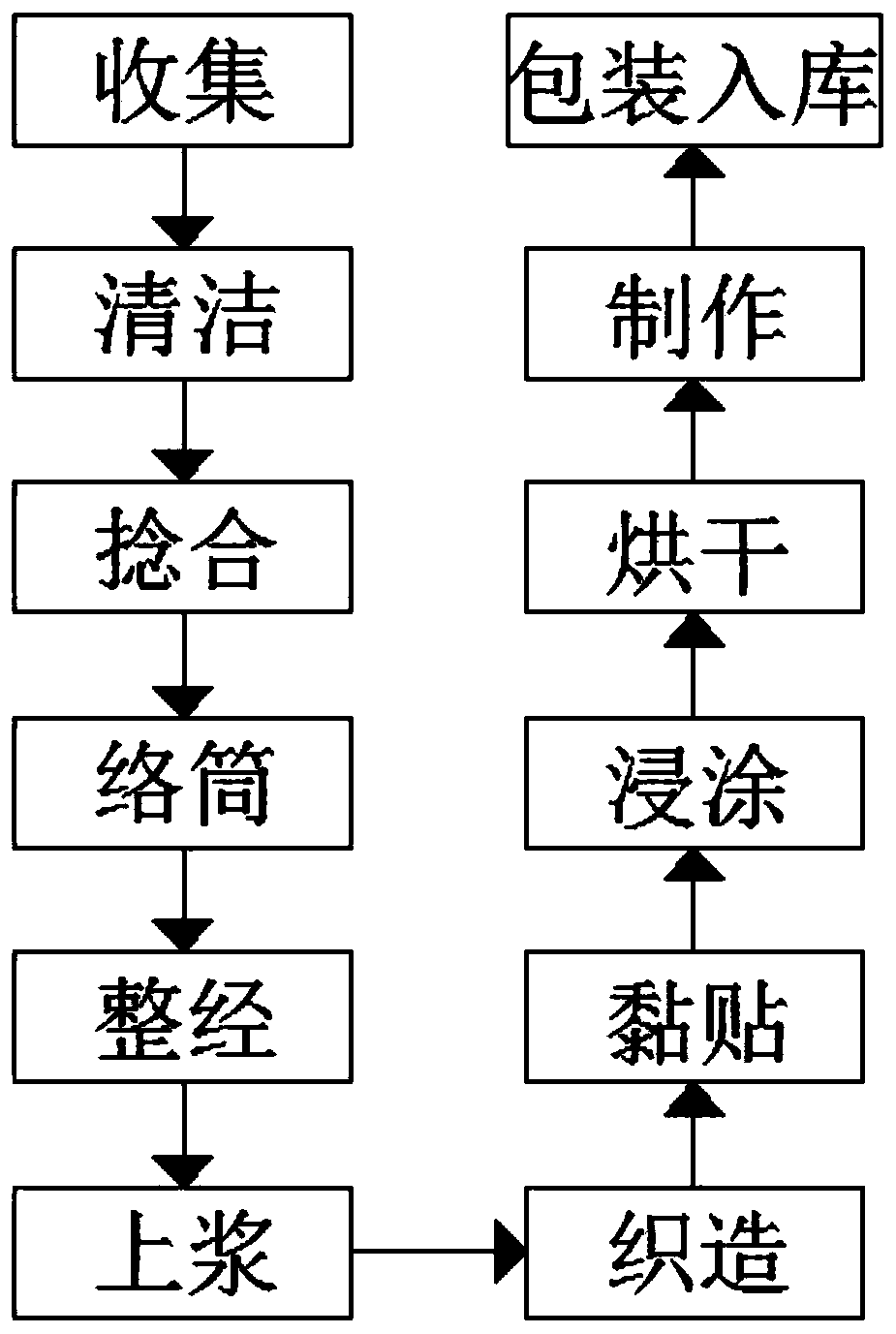

Method used

Image

Examples

Embodiment

[0031] A sweat-absorbing and breathable textile fabric, comprising a breathable layer, the breathable layer includes warp threads and weft threads, the breathable layer is made of warp threads and weft threads by plain weaving, and the warp thread is made of pure cotton or polyester fiber, The material of the weft thread is animal hair fiber, and the animal hair fiber is camel hair, and the air-permeable layer is provided with an antibacterial layer, a tensile layer and an anti-ultraviolet layer.

[0032] Preferably, the antibacterial layer is arranged on the upper surface of the air-permeable layer, and the antibacterial layer is nano-scale polyurethane or 8-hydroxyquinoline copper coating; the antibacterial layer is set to resist bacterial growth, which is conducive to sweat-absorbing and breathable textile fabrics Used for curtains, quilt covers and other textiles with long cleaning cycles.

[0033] Preferably, the tensile layer is arranged on the outside of the antibacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com