Hydraulic control circuit for an articulation assembly

A control circuit and valve assembly technology, applied in servo meter circuits, fluid pressure actuators, mechanically driven excavators/dredgers, etc., can solve the problems of small articulation degree and difficulty in maintaining articulation degree accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

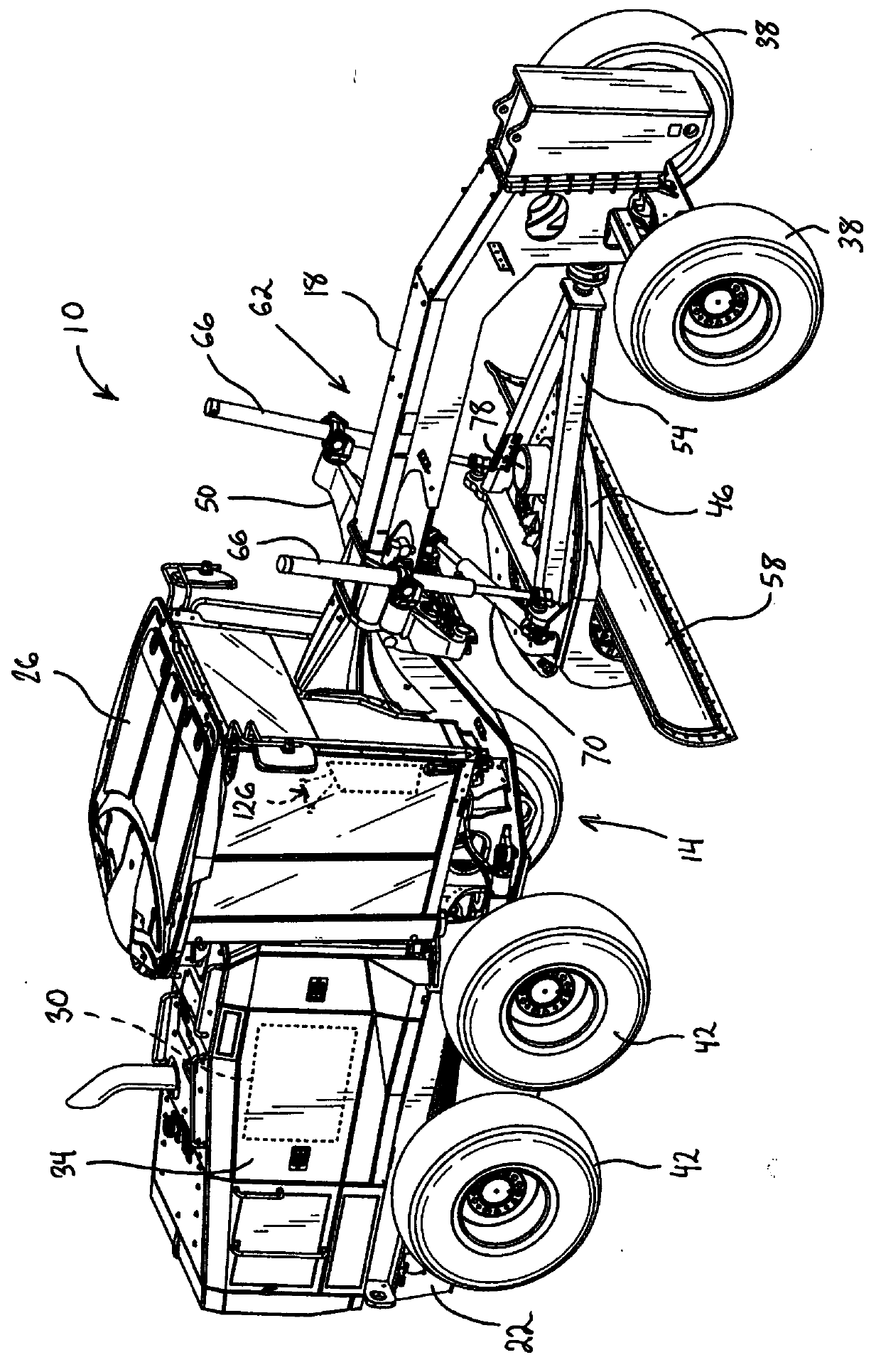

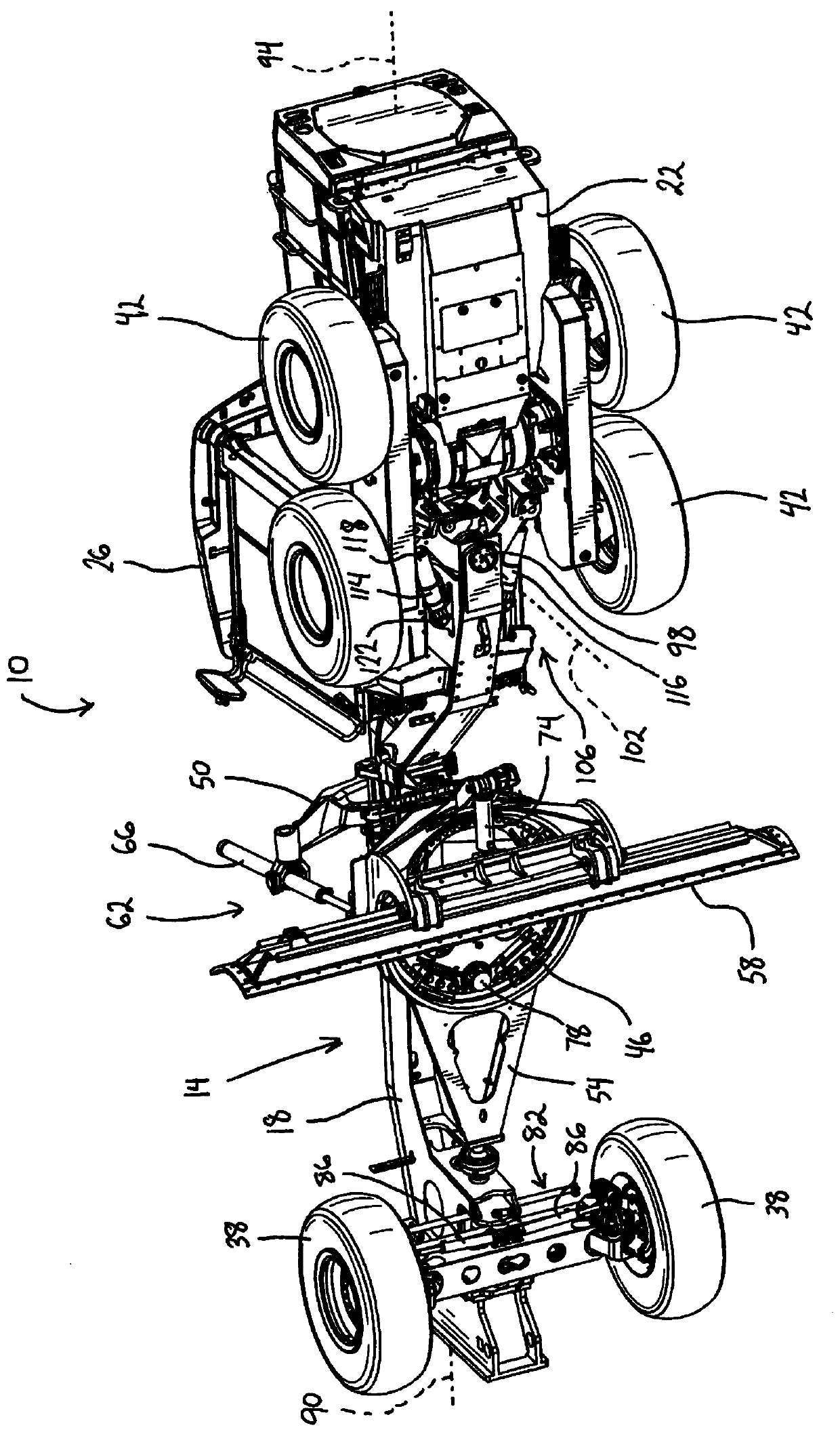

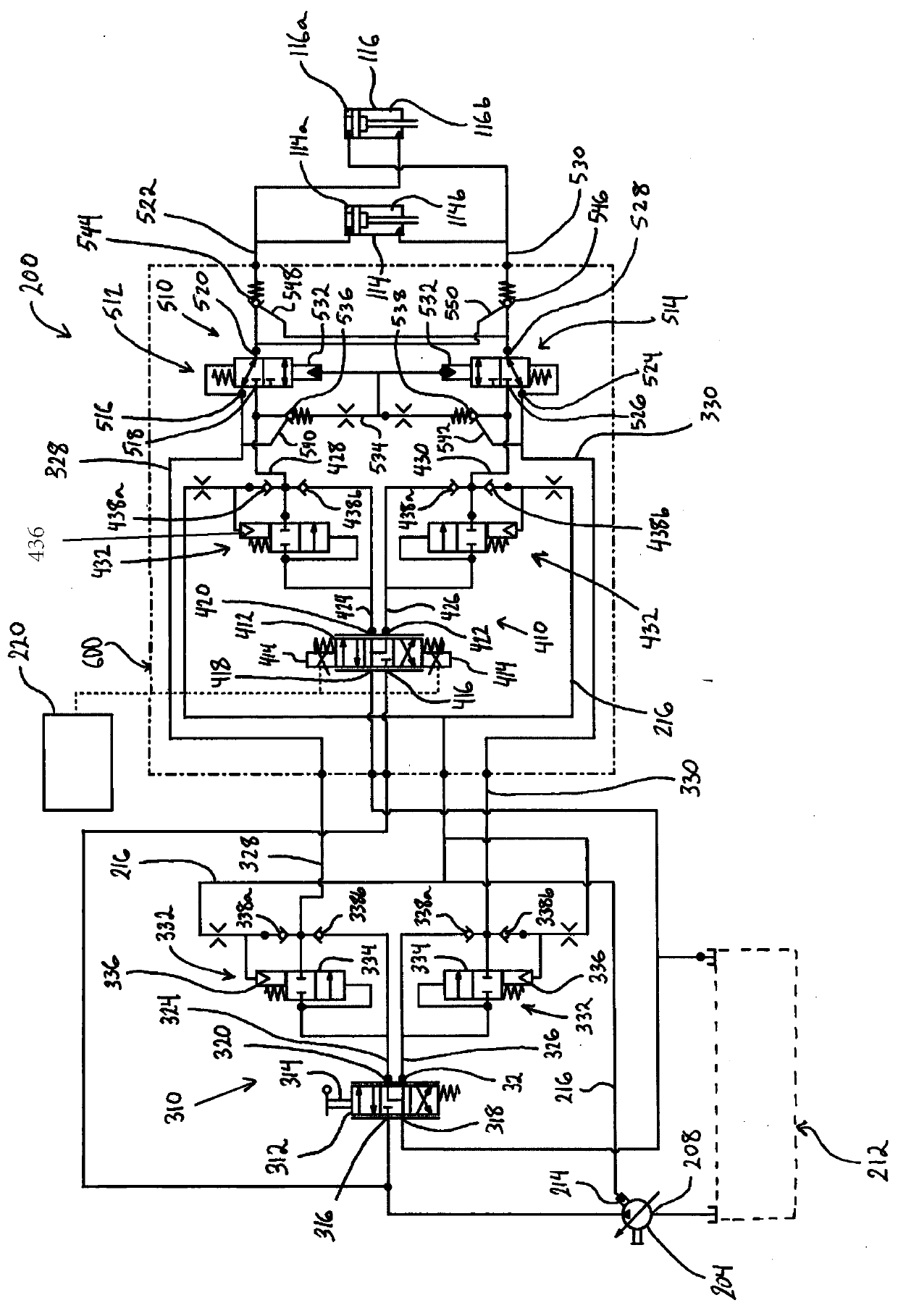

[0011] figure 1 A work vehicle is shown, which in the illustrated embodiment is a motor grader (or simply "motor grader") 10 . Motor grader 10 includes a chassis 14 having a front frame 18 and a rear frame 22 . The front frame 18 supports a cab 26 which may include an operator seat, controls for operating the motor grader 10, and the like. A prime mover 30 (eg, a diesel engine) is supported on the rear frame 22 and enclosed within a compartment 34 . Chassis 14 is supported by front wheels 38 at the front of motor grader 10 and dual-wheel or tandem rear wheels 42 at the rear of motor grader 10 .

[0012] Motor grader 10 includes a hoop 46 disposed forward of cab 26 and suspended below front frame 18 by lifter bracket 50 and drawbar 54 . A work implement, which in the illustrated embodiment is a blade 58 or a moldboard, extends transversely through circle 46 . Motor grader 10 includes blade positioning assembly 62 that allows the position and orientation of blade 58 to be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com