A water-air separation device for concentrated feed processing

A water-gas separation and concentrated feed technology, which is applied to heating devices, drying solid materials, lighting and heating equipment, etc., can solve the problems of poor drying efficiency, water can not be used for secondary heat conduction, etc., so as to avoid waste and realize water Gas separation, to achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

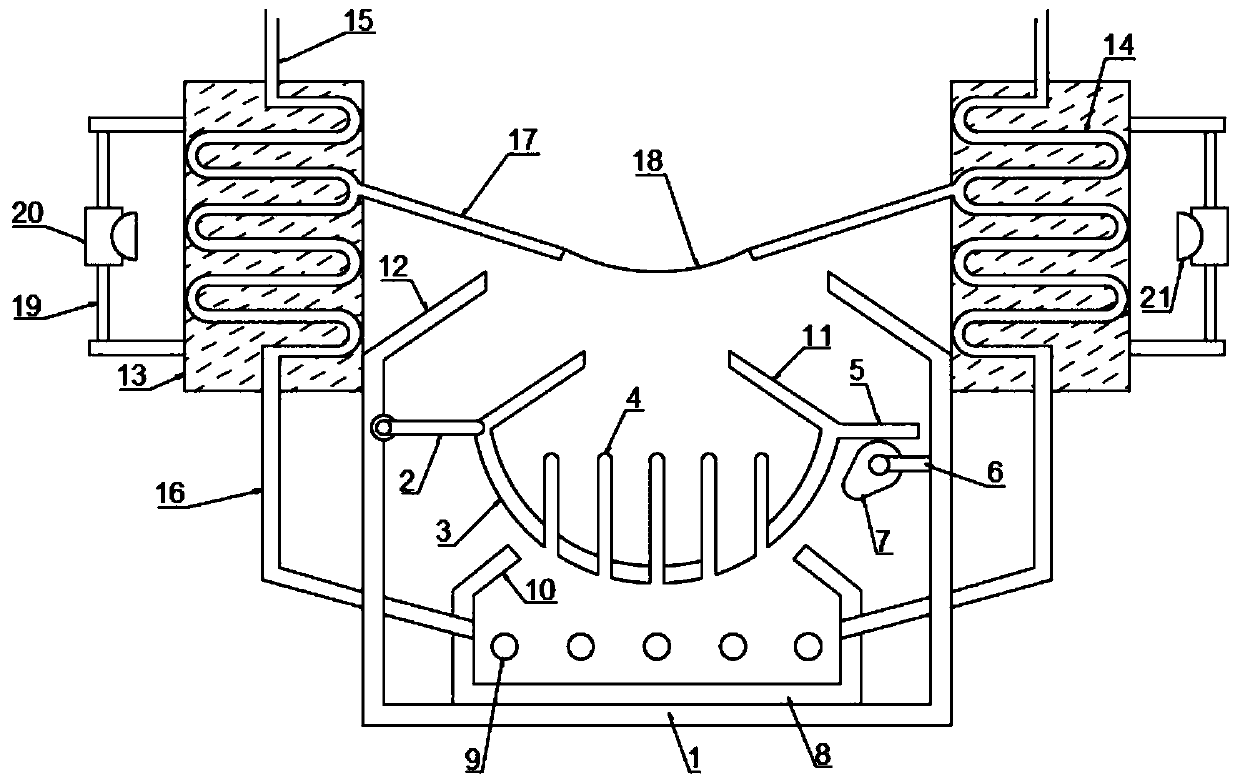

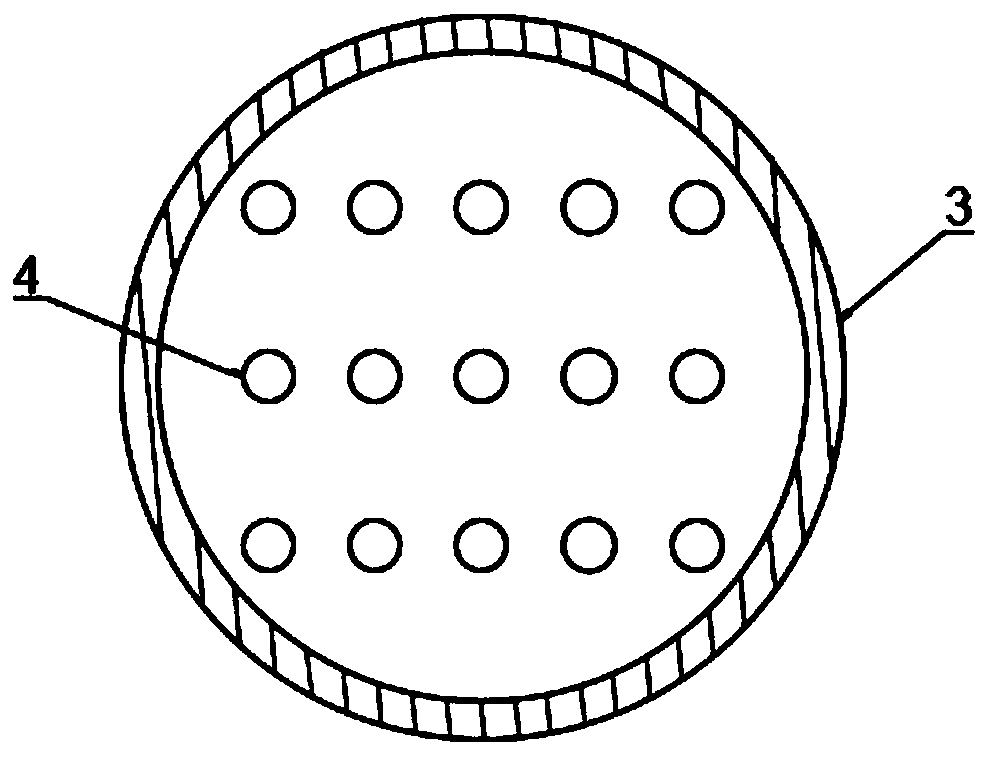

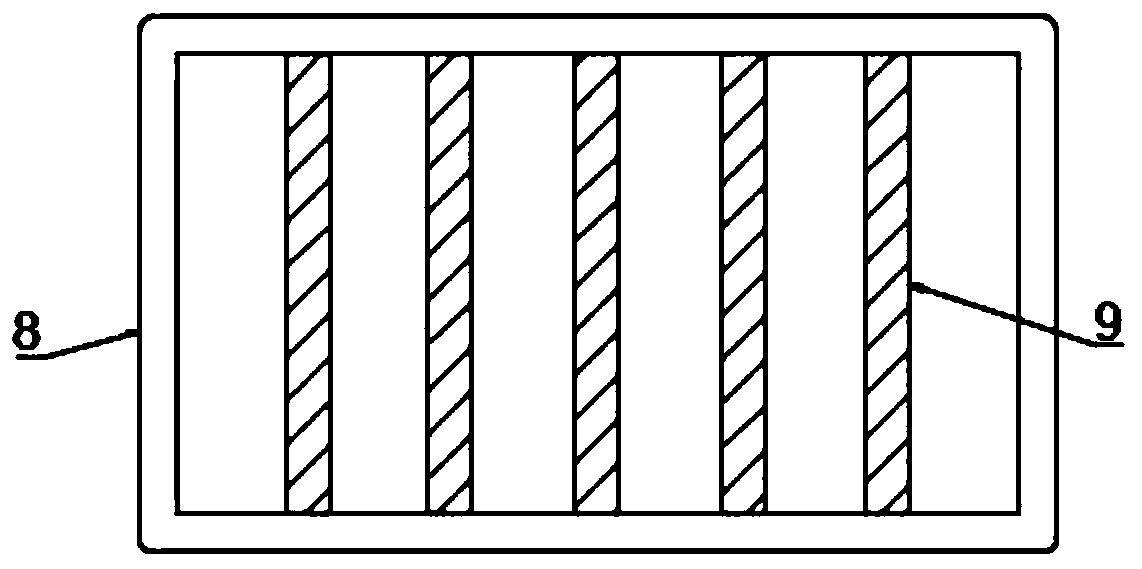

[0029] refer to Figure 1-3 , a water-air separation device for concentrated feed processing, comprising a box body 1, a rotating rod 2 is rotatably connected to one side of the inner wall of the box body 1, and the other end of the rotating rod 2 is fixed with a swing groove 3, and the inner bottom wall of the swing groove 3 An air intake pipe 4 arranged vertically downward is integrally formed, and a wobble plate 5 arranged symmetrically with the rotating rod 2 is fixed on the outer wall of the oscillating groove 3, and a wobble plate 5 is arranged between the lower side wall of the wobble plate 5 and the inner wall of the box body 1. mechanism, the swing mechanism includes a fixed rod 6 fixed on the inner wall of the box body 1, a motor one is fixed on the end of the fixed rod 6 far away from the inner wall of the box body 1, and a cam 7 is fixed on the driving end of the motor one, and the motor one drives the cam 7 to rotate. When the longer end of the cam 7 is turned to ...

Embodiment 2

[0036] refer to Figure 2-4, a water-air separation device for concentrated feed processing, comprising a box body 1, a rotating rod 2 is rotatably connected to one side of the inner wall of the box body 1, and the other end of the rotating rod 2 is fixed with a swing groove 3, and the inner bottom wall of the swing groove 3 An air intake pipe 4 arranged vertically downward is integrally formed, and a wobble plate 5 arranged symmetrically with the rotating rod 2 is fixed on the outer wall of the oscillating groove 3, and a wobble plate 5 is arranged between the lower side wall of the wobble plate 5 and the inner wall of the box body 1. mechanism, the swing mechanism includes a limit plate 22 fixed on the inner wall of the box body 1, a rack 23 is inserted on the limit plate 22, a motor 2 is fixed inside the box body 1, and the driving end of the motor 2 is fixed on the rack 23 The incomplete gear 24 on one side, when the motor 2 drives the incomplete gear 24 to mesh with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com