A Fabric Defect Detection Method Based on Light Field Camera Depth Information Extraction

A light field camera, depth information technology, applied in image analysis, image enhancement, instrumentation, etc., can solve problems such as not well solved, vignetting effect, complex target effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

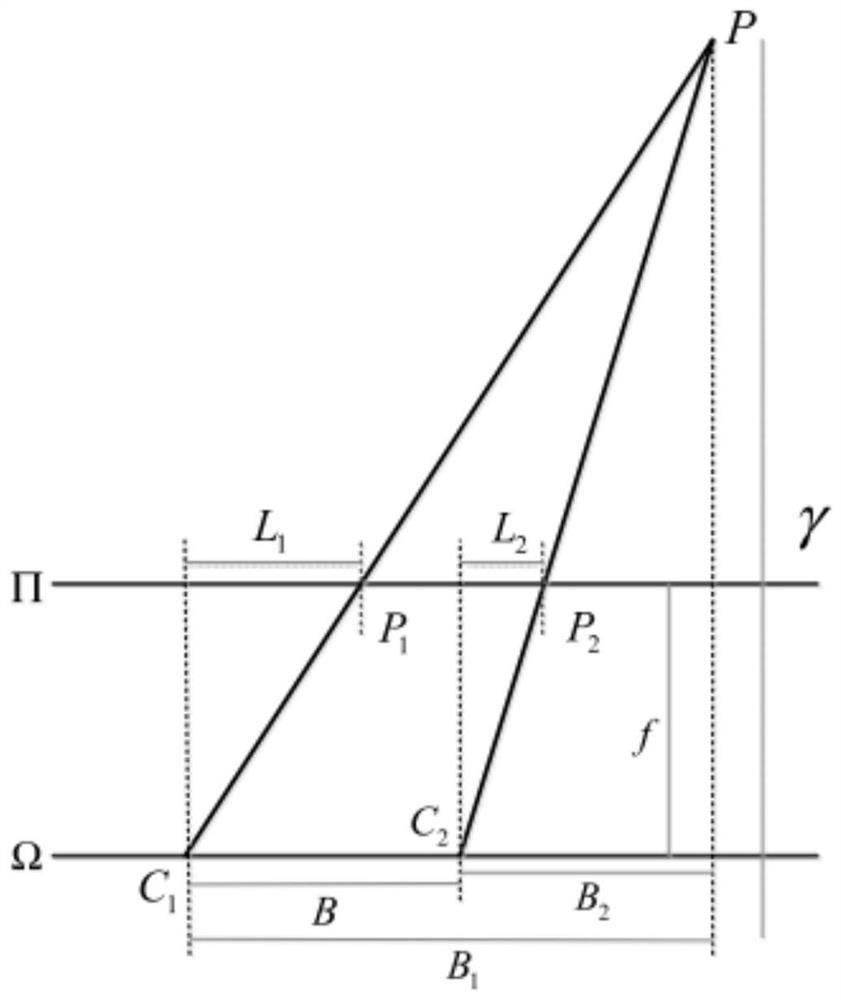

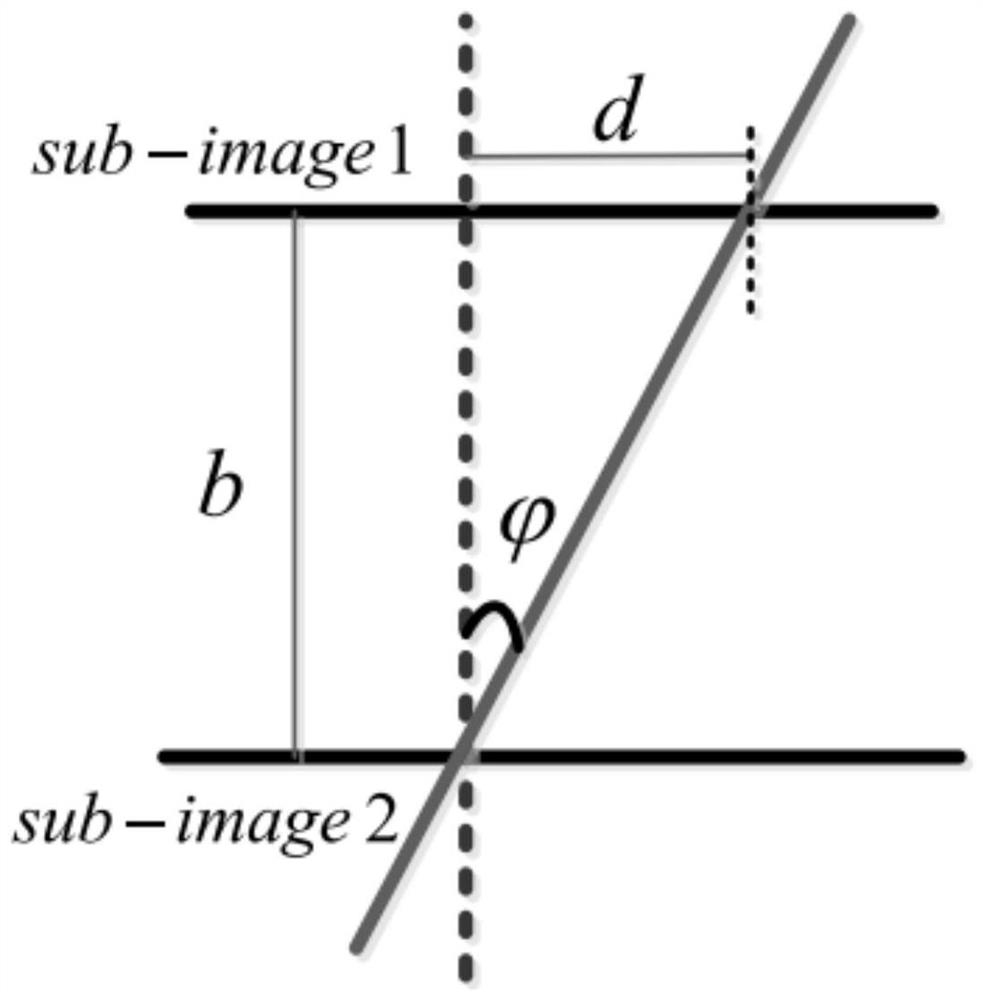

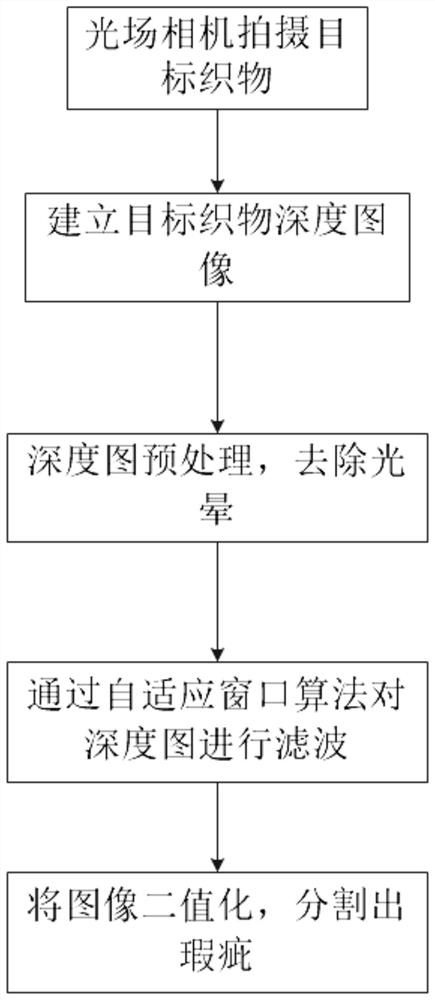

[0042] The present invention comprises the following steps:

[0043] Step 1: Collect a set of multi-view images with a light field camera.

[0044]Step 1.1: Shoot the target fabric with a light field camera in a uniform light field, extract the RAW file and white image file in the light field camera, decode the extracted RAW file first, and then color correct it, which needs to use Matlab light field toolkit, this toolkit is developed by D.G.Dansereau et al. Currently, there are two versions of toolbox0.3 and toolbox0.4. What is used in this embodiment is toolbox0.4, and the white image file will be used when decoding the image , each light field camera will have its own white image file, the toolkit reads the WhiteImagesDataBase mapping table, and the toolkit selects the most suitable white image and microlens grid model to obtain the light field image in Bayer format. Then perform frequency domain filtering on the image to perform demosaic operation on the image to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com