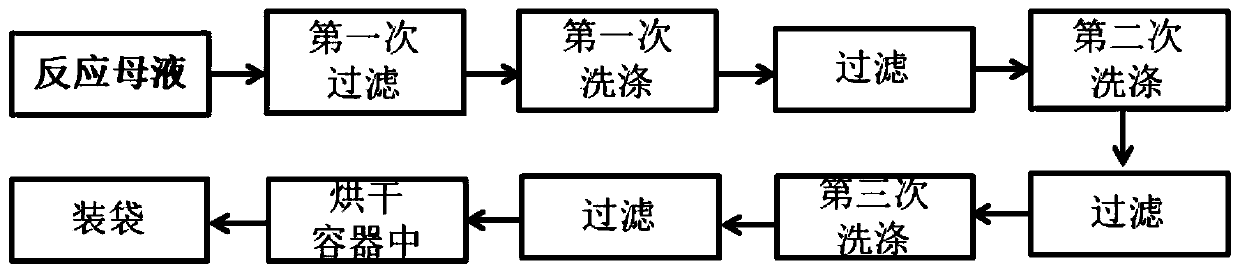

Container with filtering, washing and storage functions

A storage function and container technology, applied in the direction of fixed filter elements, containers, large containers, etc., can solve the problems of frequent product transfers, heavy labor, poor safety, etc., to reduce multiple transfers, reduce product losses, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

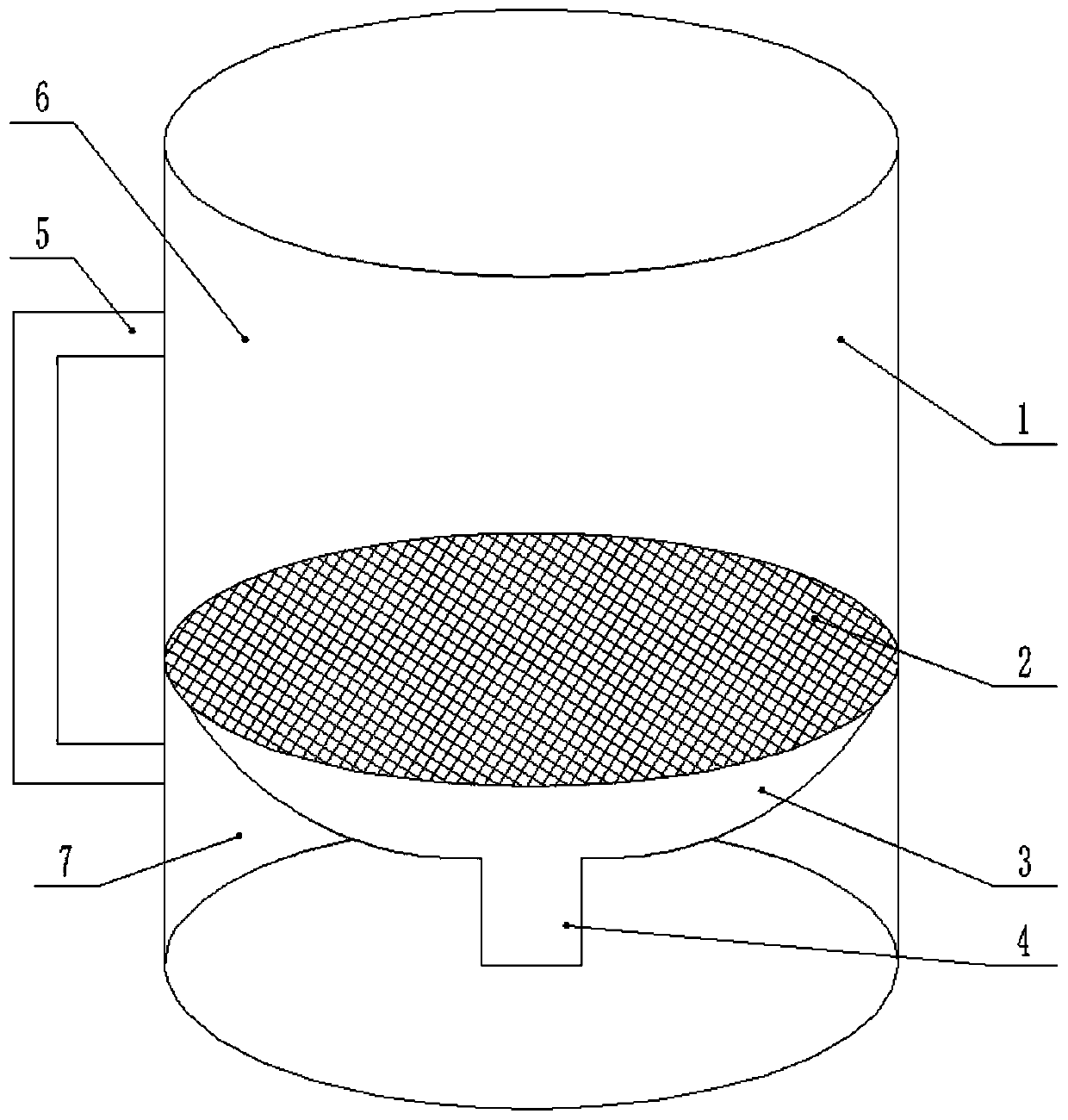

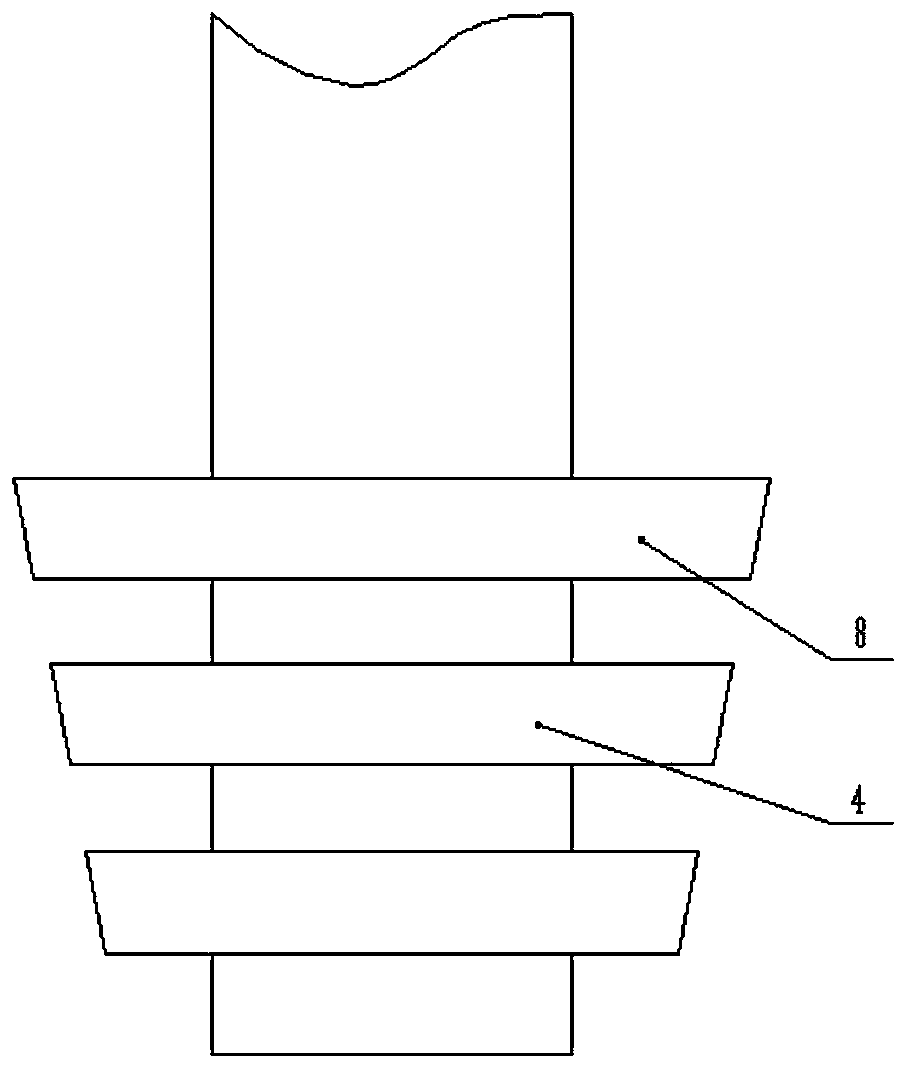

[0028] Such as figure 2 As shown, a container with integrated filtering, washing and storage functions includes a column body 1, a cavity that penetrates up and down inside the column body 1, and a glass sand board 2 is provided inside the cavity, and the glass sand board The outer edge of 2 is closely attached to the side wall of the cavity, and the glass sand plate 2 divides the cavity into an upper receiving cavity 6 and a lower installation cavity 7, and the installation cavity 7 at the bottom of the glass sand plate 2 is installed with The spherical receiving hopper 3, the bottom of the spherical receiving hopper 3 is connected with the discharge pipe 4 communicating with the spherical receiving hopper 3, and the bottom of the discharge pipe 4 is arranged inside the installation cavity 7. The bottom of the discharge pipe 4 is arranged in the inside of the installation chamber 7 and is arranged in this way in order to ensure that the bottom of the installation chamber 7 c...

Embodiment 2

[0043] The container is a circular columnar container, made of ordinary glass, a glass sand plate 2 with a pore diameter of 5um is installed in the lower 1 / 3, and the upper part maintains a volume of 30ml. The size is 14mm, and a suitable handle 5 is arranged on the outside of the container; the discharge pipe 4 is plugged with a rubber stopper when washing, and is opened when filtering. During storage, the discharge pipe 4 is plugged with a rubber plug, and the accommodating chamber 6 is plugged with a large rubber plug to prevent moisture.

Embodiment 3

[0045] The container is a circular columnar container made of boric acid glass. A glass sand plate 2 with a pore diameter of 1um is installed in the lower 1 / 3, and the upper part maintains a volume of 100ml. The size is 19mm, and a suitable handle 5 is arranged on the outside of the container; the discharge pipe 4 is plugged with a rubber stopper during washing, and is opened when filtering. During storage, the discharge pipe 4 is plugged with a rubber plug, and the accommodating chamber 6 is plugged with a large rubber plug to prevent moisture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com