Needle bar swinging mechanism of sewing machine

A swing mechanism and sewing machine technology, applied in the direction of sewing machine needle holders, sewing machine components, sewing equipment, etc., can solve the problems of cost increase, cost increase, and complex motor composition, and achieve reduced capacity, miniaturization, high speed and high speed. The effect of precision zigzag sewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

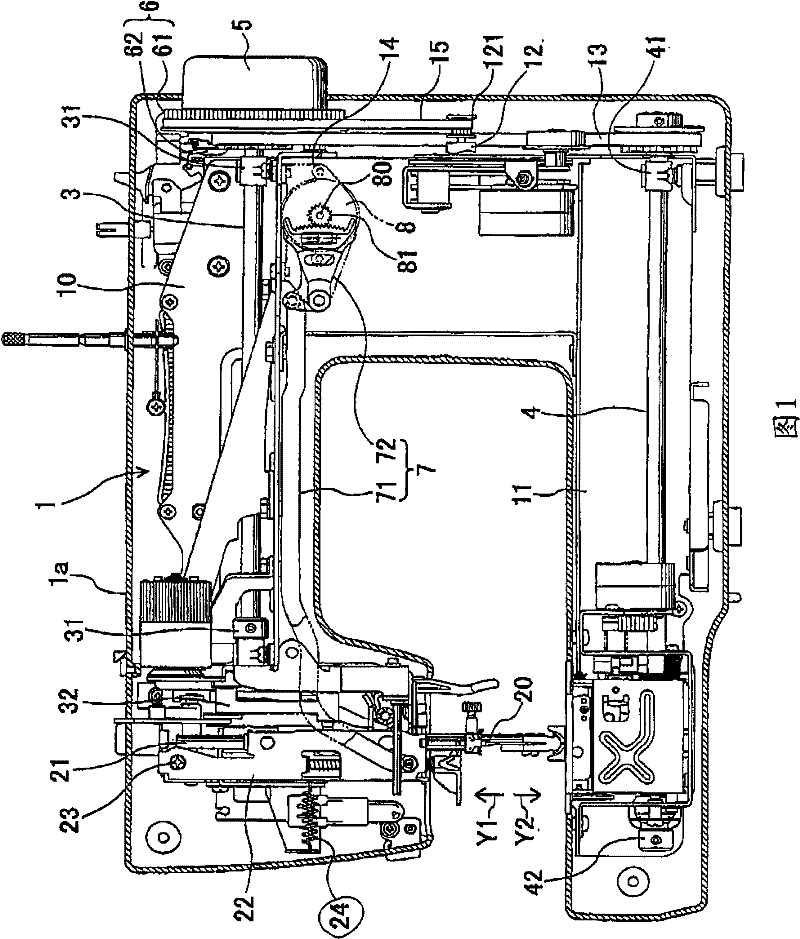

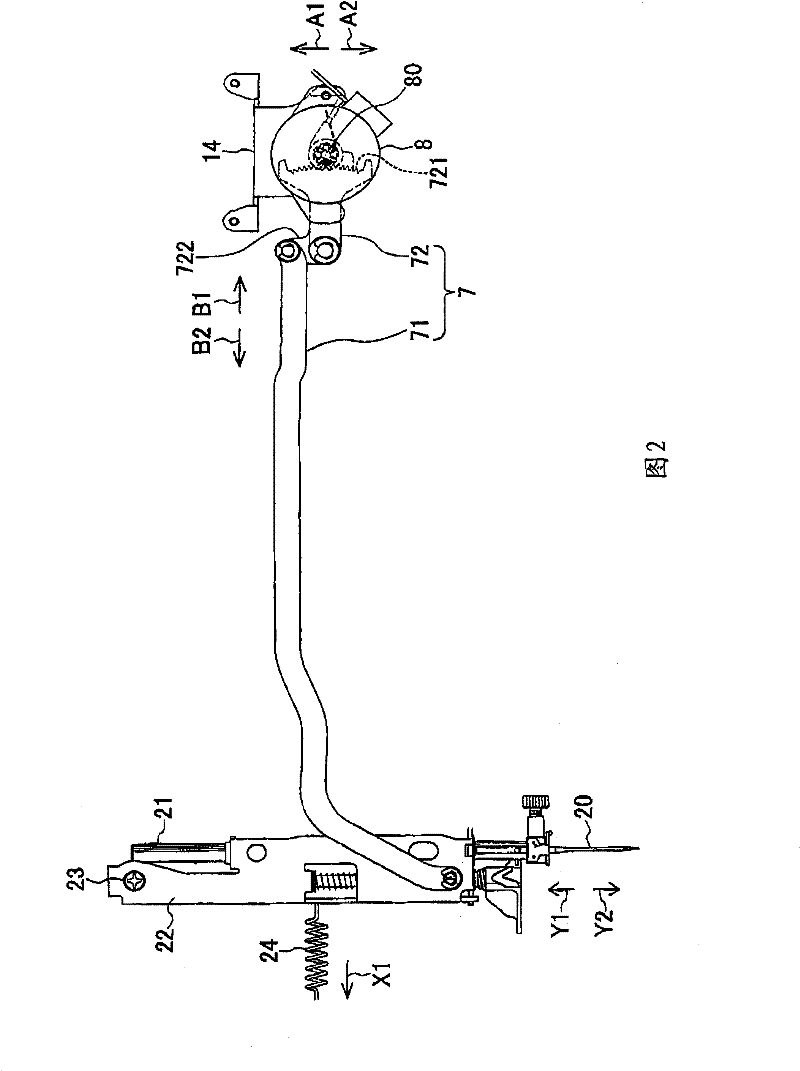

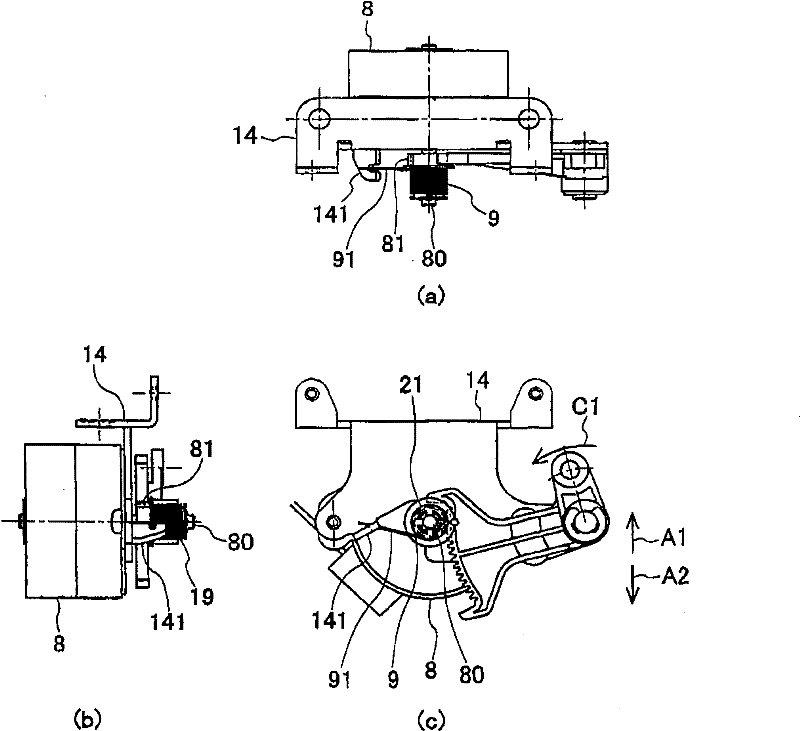

[0028] Such as figure 1 As shown, a body 1 as a main component of the sewing machine is covered by a casing 1 and includes a cantilever frame 10 and a base frame 11 . The cantilever frame 10 and the base frame 11 are not castings, but mainly formed of a sheet metal formed body formed by stamping a metal plate having a predetermined thickness. On the cantilever machine frame 10, a needle bar 21 capable of holding a needle 20 is provided so as to be movable up and down, and an upper shaft 3 along the horizontal direction is provided rotatably. The upper shaft 3 is supported and freely rotatable by a pair of bearings 31 fixed to the boom frame 10 . One end of upper shaft 3 fixes hand wheel 5 and pulley 6 ( figure 1 center right). The pulley 6 is formed with a driven wheel 61 of a large diameter portion and a first timing wheel 62 . Below the pulley 6, the drive belt 15 is suspended between the motor pulley 121 fixed on the drive motor 12 fixed to the cantilever machine frame ...

Embodiment approach 2

[0039] The sewing machine in the second embodiment has almost the same configuration as the sewing machine in the first embodiment, except for the needle bar holding arm 22 and the needle bar spring 24, and has the same effects as those in the first embodiment. Therefore, a detailed description of the same configuration as that of Embodiment 1 is omitted.

[0040] Such as Figure 4 As shown, in the sewing machine according to the second embodiment, the needle bar holding arm 22 is urged in one direction in the left-right direction by the needle bar urging member (urging member) 25 . The needle bar holding arm 22 has an engaging portion 221 formed on a side surface (left side in the figure). Furthermore, the needle bar urging member 25 has a pressing member 251 and a torsion spring 252 . The pressing member 251 has a contact portion 253 that contacts the engaging portion 221 of the needle bar holding arm 22 and pushes the needle bar holding arm 22 in one direction, and a lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com