Electrostatic filter unit and ventilation device with electrostatic filter unit

A ventilation device and filter technology, applied in the direction of electrode conveying device, external electrostatic separator, electrostatic separation, etc., can solve problems such as complex structure, large number of filter parts, and high risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

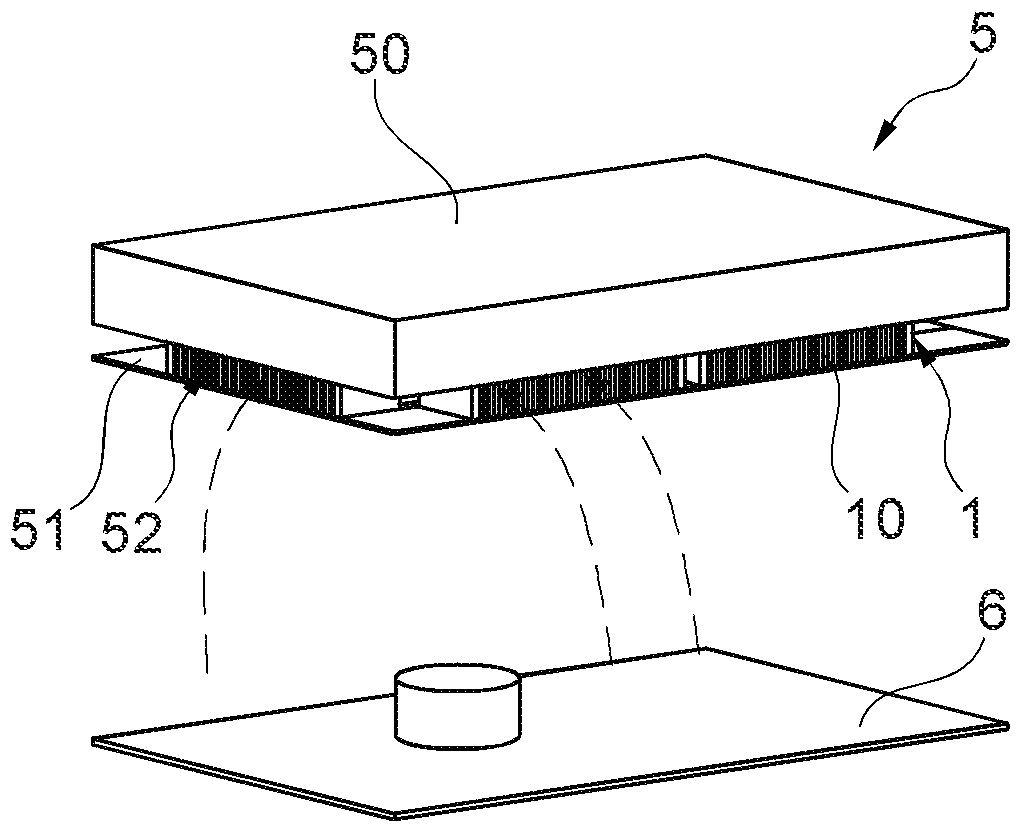

[0045] exist figure 1 An embodiment of a ventilating device 5 according to the invention is shown in , which shows a cooker hood in the form of a ceiling vent. In the embodiment shown, the ventilation device 5 has a ventilation housing 50 and a baffle 51 which is located below the ventilation housing 50 , that is to say in front of the bottom side of the ventilation housing 50 in the direction of flow. Between the bottom side of the ventilation housing 50 and the baffle 51 there is formed a suction opening 52 , which can also be referred to as a suction gap. A plurality of filter units 1 are accommodated in the suction opening 52 . In the illustration shown, two filter units 1 are arranged along the width of the ventilation device 5 and one filter unit 1 is arranged along the depth of the ventilation device 5 . The ventilation device 5 is arranged above the cooking zone 6 and can be accommodated, for example, in a ceiling (not shown), wherein at least the suction opening 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com