A press bottle with a bag

A bottle body and inner bag technology, applied in the field of pressed bottles with bags, can solve the problems of affecting product shelf life, complex structure, and many residues, and achieve the effect of streamlining the structure, reducing residues, and less residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

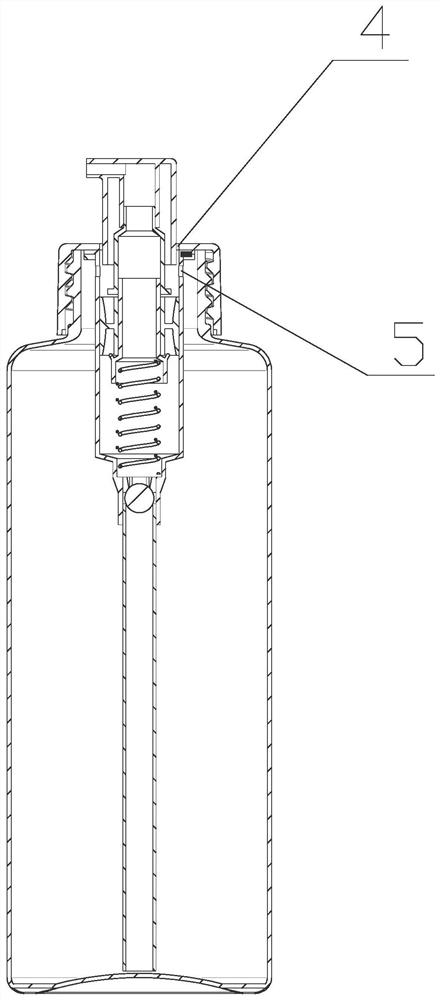

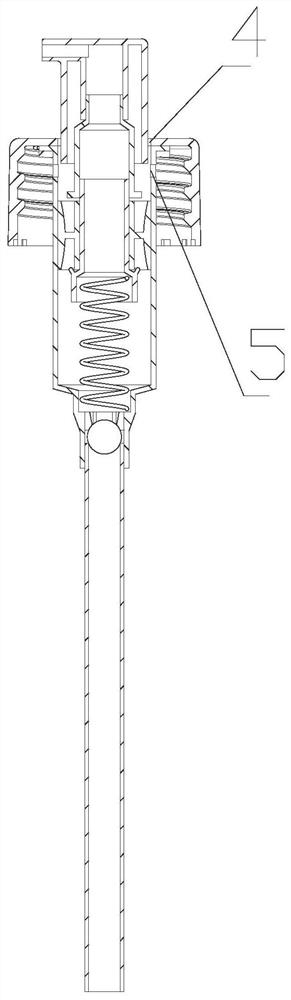

[0045] A squeeze bottle with a pouch, such as Figure 3-8 As shown, it includes an inner bag 3, a bottle body 22 and a pump head 1 connected to the bottle body 22;

[0046] The inner bag 3 is located in the bottle body 22, the opening of the inner bag 3 is connected with the opening of the bottle body 22, and the bottom of the bottle body 22 has a through hole III 23 communicating with the outside;

[0047] The minimum elastic modulus of the material of the bottle body 22 is not less than 850MPa, and it is mainly composed of the inner layer of the bottle and the outer layer of the bottle. The inner layer of the bottle is made of PP material, and the outer layer of the bottle is made of PP soft touch material. The inner material of the bottle is not bonded to EVOH, the thickness of the inner layer of the bottle is 0.2mm, and the thickness of the outer layer of the bottle is 0.6mm;

[0048] The inner bag 3 includes an EVOH layer and an LDPE layer located on the outermost side o...

Embodiment 2

[0062] A press bottle with bag, which is basically the same as Example 1, the difference lies in the thickness of each layer of the bottle body and the inner bag, the thickness of the inner layer of the bottle is 0.3mm, the thickness of the outer layer of the bottle is 0.3mm, and the thickness of the EVOH layer The thickness of the LDPE layer is 0.1mm, and the thickness of the layer formed by the adhesive is 0.01mm.

Embodiment 3

[0064] A press bottle with bag, which is basically the same as Example 1, except that the thickness of each layer of the bottle body and the inner bag is different, the thickness of the inner layer of the bottle is 0.1mm, the thickness of the outer layer of the bottle is 1mm, and the thickness of the EVOH layer is 0.07mm, the thickness of the LDPE layer is 0.2mm, and the thickness of the layer formed by the adhesive is 0.02mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com