Waterproof alkali-liquid-free quick-setting agent having water reducing function, and preparation method thereof

A waterproof, accelerator technology, applied in the field of building materials, can solve the problems of increase, decrease of concrete strength, strong alkali corrosion, etc., and achieve the effect of high application value, high early strength, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

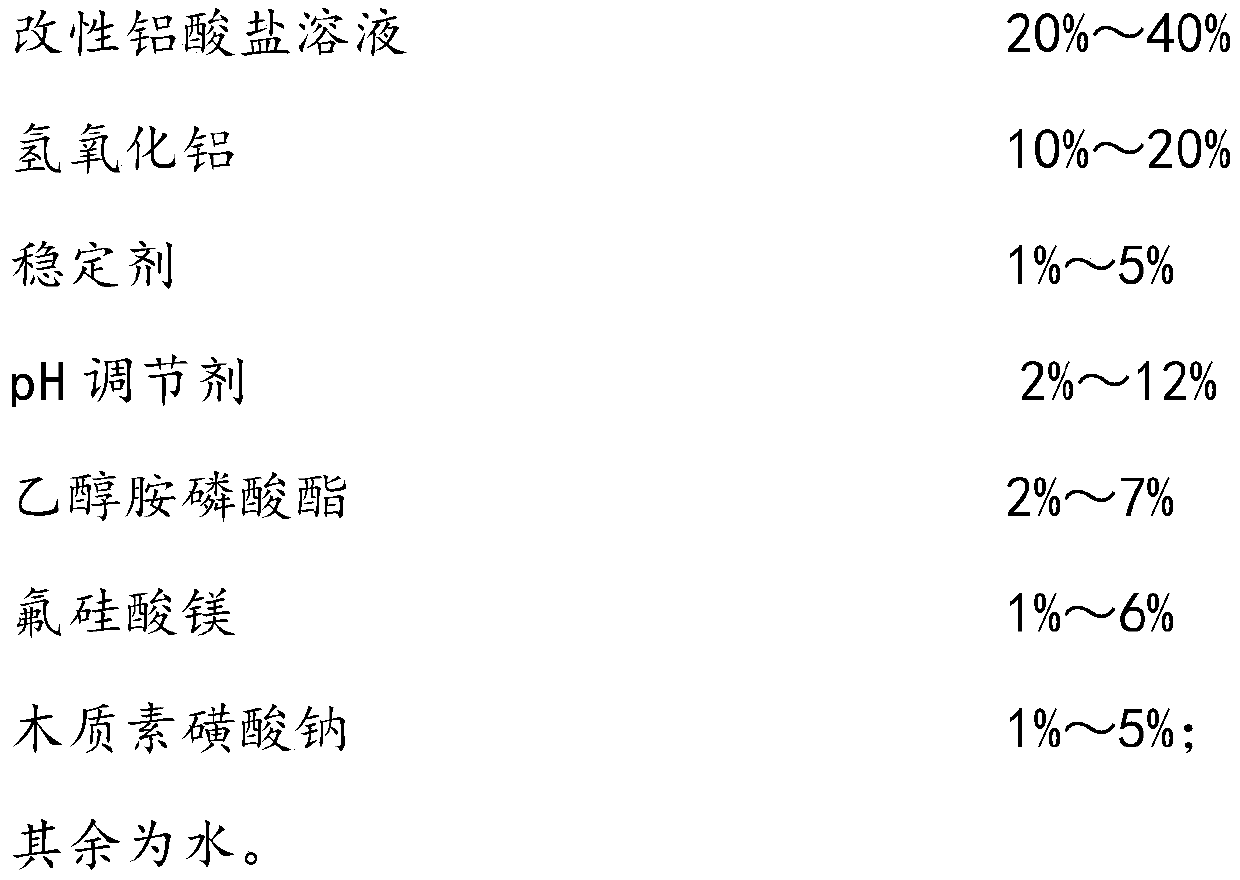

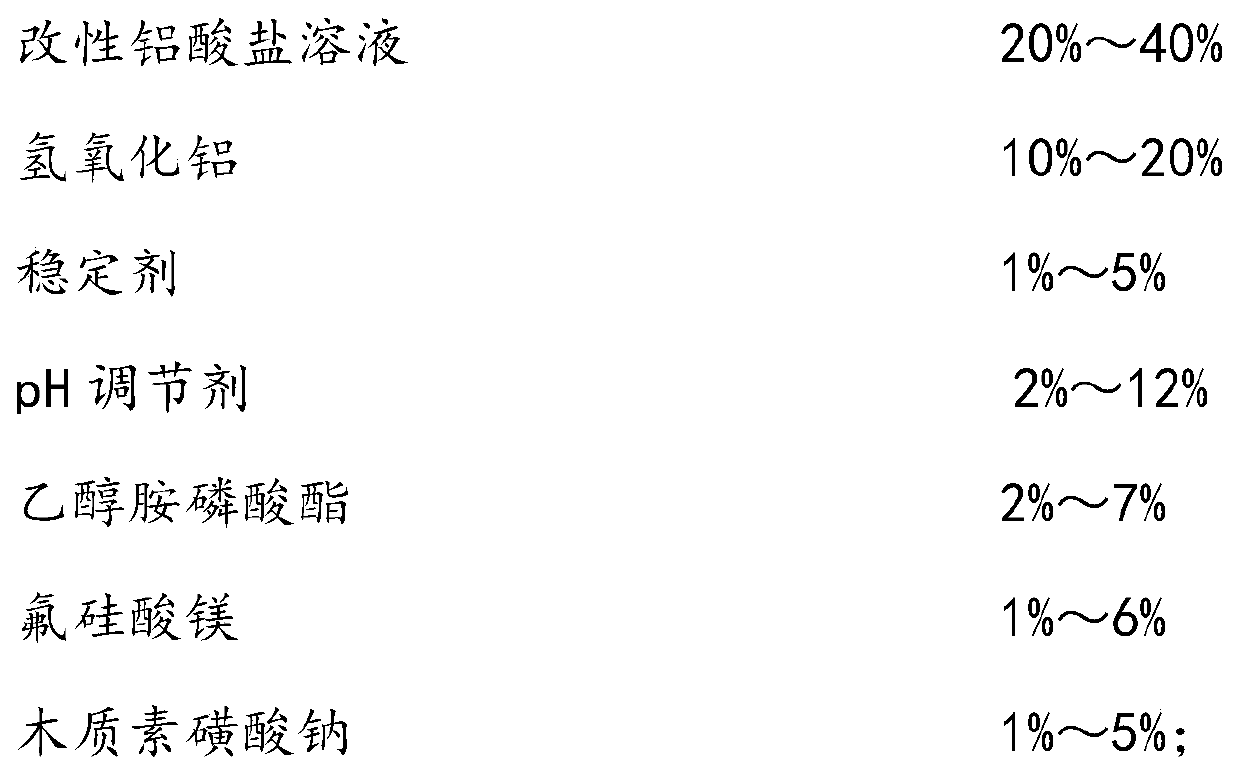

Method used

Image

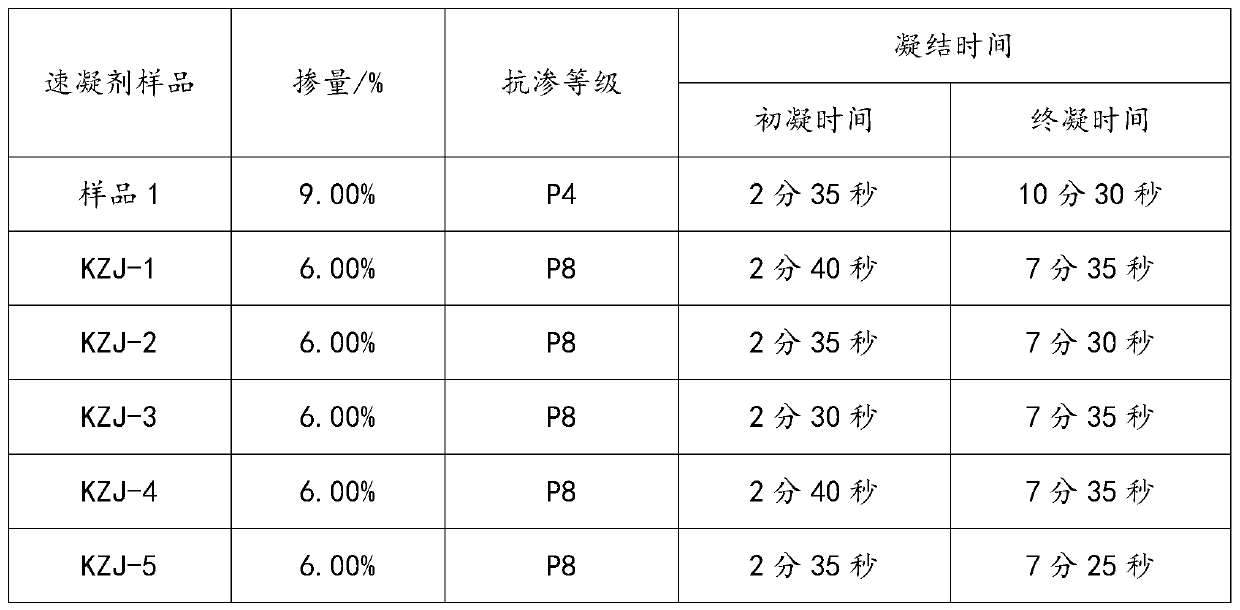

Examples

Embodiment 1

[0028] (1) Preparation of modified aluminate: add 20.00g of stearic acid into the reaction kettle, heat up to 75°C, heat to molten state, turn on the stirring device, then add 2.00g of lithium hydroxide at one time, stir evenly, React for 3.0 hours, when the temperature is lowered to 35°C, add 35.00g of aluminum citrate and 37.00g of water to the reaction kettle, carry out ultrasonic reaction for 3 hours, lower to normal temperature, then add 6.00g of calcium hydroxide, react for 0.5h, and obtain modified aluminum salt;

[0029] (2) Preparation of stabilizer: Add 100.00g (trimethylsilyl) acetic acid to the reaction kettle, turn on the stirring device, and then add 85.00g 2-(methylamino)ethanol, 10.00g 2-(ethylamino) Ethanol and 2.50g p-toluenesulfonic acid, after stirring evenly, start to heat up, and react at 75°C for 3.0h to prepare a stabilizer;

[0030] (3) Add 4.00 g of the stabilizer prepared in step (2) and 30.00 g of water into the reaction kettle for stirring, then a...

Embodiment 2

[0032] (1) Preparation of modified aluminate: 23.00g of stearic acid is added to the reaction kettle, the temperature is raised to 80°C, heated to a molten state, the stirring device is turned on, and 1.80g of lithium hydroxide is added at one time, and stirred evenly, React for 4.0 hours, when the temperature is lowered to 40°C, add 30.00g of aluminum citrate and 37.20g of water to the reaction kettle, carry out ultrasonic reaction for 3 hours, lower to normal temperature, then add 8.00g of calcium hydroxide, react for 1.0h, and obtain modified aluminum salt;

[0033] (2) Preparation of stabilizer: Add 100.00g (trimethylsilyl) acetic acid to the reaction kettle, turn on the stirring device, and then add 80.00g 2-(diisopropylamino)ethanol, 15.00g 2-(methylamine) Base) ethanol and 3.60g of concentrated sulfuric acid, after stirring evenly, start to heat up, and react for 4.0h at 65°C to prepare a stabilizer;

[0034] (3) Add 3.00g of the stabilizer prepared in step (2) and 30....

Embodiment 3

[0036] (1) Preparation of modified aluminate: add 16.00g of stearic acid into the reaction kettle, heat up to 70°C, heat to a molten state, turn on the stirring device, then add 2.60g of lithium hydroxide at one time, stir evenly, React for 4.0 hours, when the temperature is lowered to 45°C, add 26.00g of aluminum citrate and 48.40g of water to the reaction kettle, carry out ultrasonic reaction for 4 hours, lower to normal temperature, then add 7.00g of calcium hydroxide, react for 1.0h, and obtain modified aluminum salt;

[0037] (2) Preparation of stabilizer: Add 100.00g (trimethylsilyl) acetic acid to the reaction kettle, turn on the stirring device, and then add 90.00g 2-(ethylamino)ethanol, 12.00g 2-(methylamino) Ethanol and 2.00g of concentrated sulfuric acid were stirred evenly, and then the temperature was raised, and the temperature was raised to 70°C for 3.5 hours to prepare a stabilizer;

[0038](3) 4.00g of the stabilizer prepared in step (2) and 30.00g of water a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap