Multilayered assembled house

A prefabricated and housing technology, applied in the direction of construction, building construction, etc., to achieve the effects of increased contact area, improved pull-out resistance, and increased grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

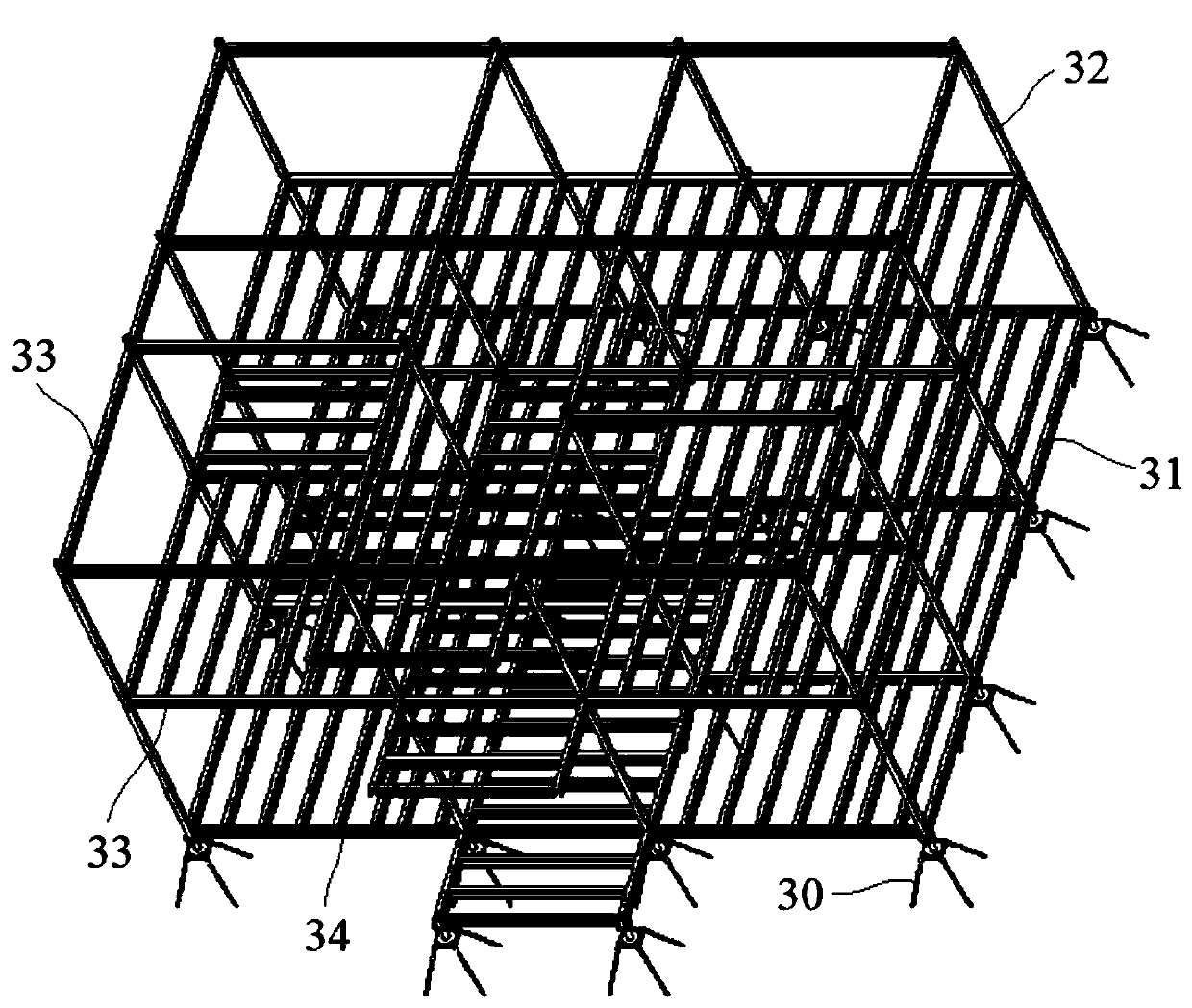

[0033] Embodiment 1: A multi-storey prefabricated house, including several ground pile assemblies 30, a ground floor frame beam assembly 31 connected above the ground pile assemblies 30, and a multi-layer frame beam installed above the ground floor frame beam assembly 31 through several columns 32 Component 33;

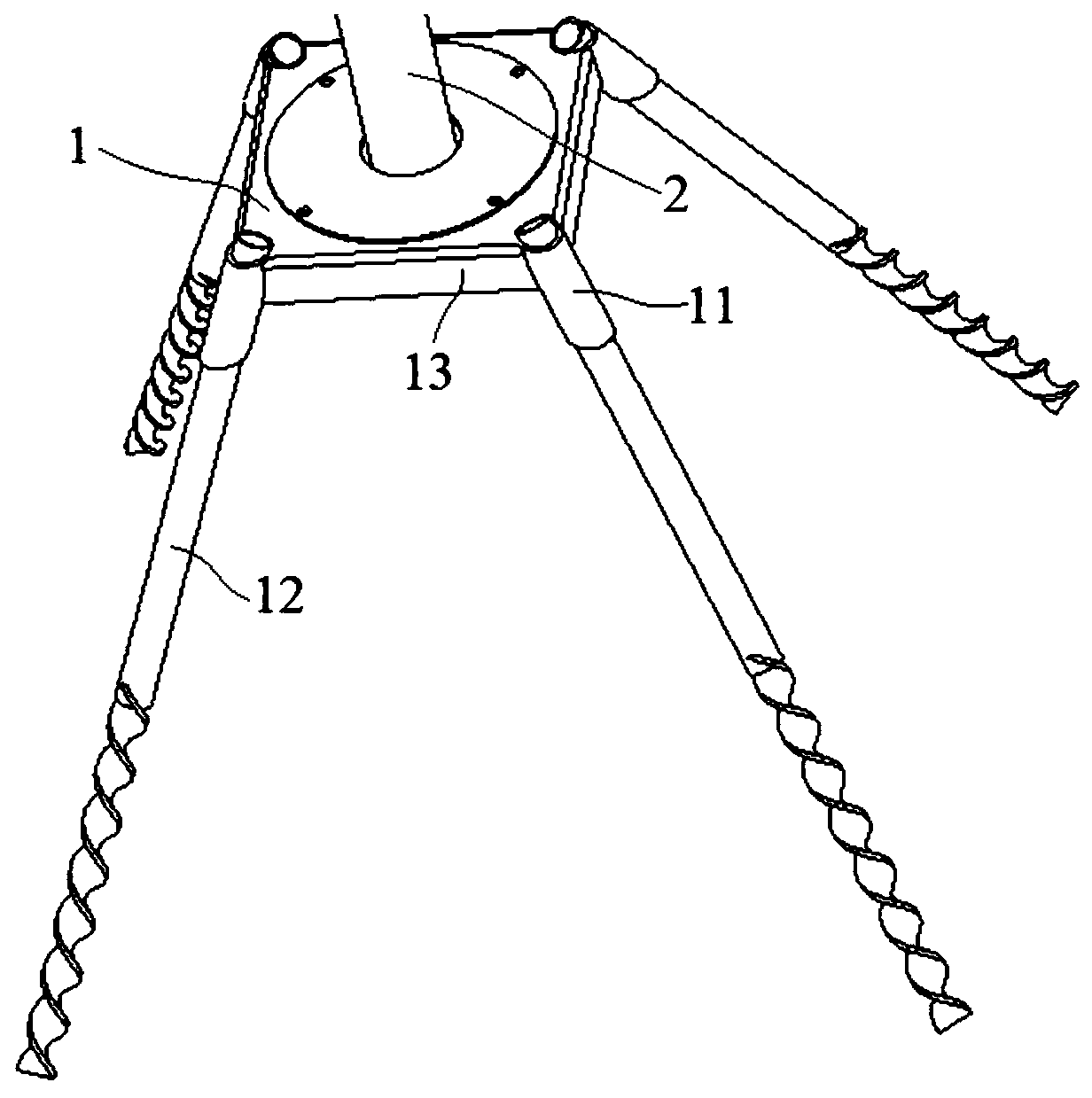

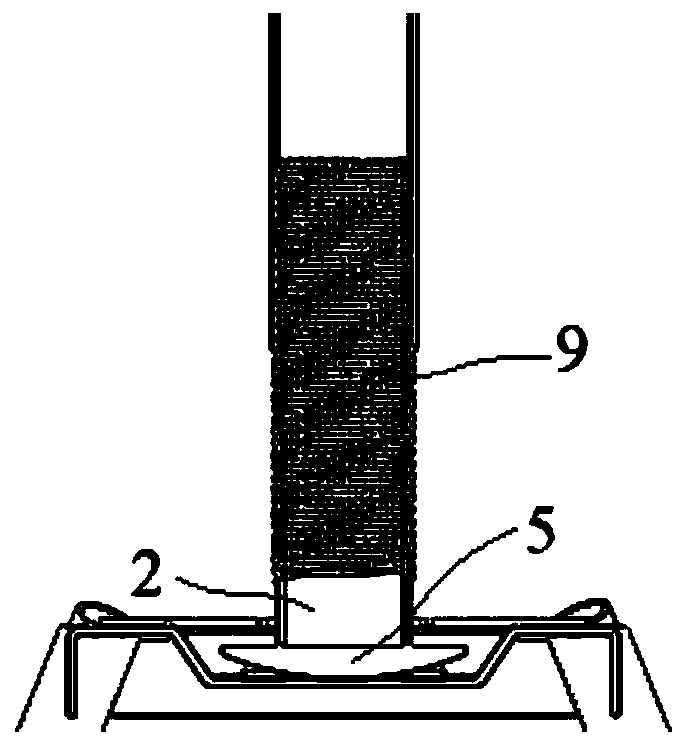

[0034] The ground pile assembly 30 further includes a base plate 1, several installation sleeves 11 and foundation piles 12, the installation sleeves 11 are fixedly connected to the corners of the base plate 1, the upper end of the foundation pile 12 is connected to the lower end of the installation sleeve 11, The foundation pile 12 is inclined outwards to form an obtuse angle with the base plate 1. There is a groove 4 in the center of the base plate 1, and a connecting column 2 is installed in the groove 4. The connecting column 2 The lower end is connected with an arc-shaped block 5, which is embedded in the groove 4 of the substrate 1, and a gasket 6 is arranged in...

Embodiment 2

[0039] Embodiment 2: A multi-storey prefabricated house, including several ground pile assemblies 30, a ground floor frame beam assembly 31 connected above the ground pile assemblies 30, and a multi-layer frame beam installed above the ground floor frame beam assembly 31 through several columns 32 Component 33;

[0040] The ground pile assembly 30 further includes a base plate 1, several installation sleeves 11 and foundation piles 12, the installation sleeves 11 are fixedly connected to the corners of the base plate 1, the upper end of the foundation pile 12 is connected to the lower end of the installation sleeve 11, The foundation pile 12 is inclined outwards to form an obtuse angle with the base plate 1. There is a groove 4 in the center of the base plate 1, and a connecting column 2 is installed in the groove 4. The connecting column 2 The lower end is connected with an arc-shaped block 5, which is embedded in the groove 4 of the substrate 1, and a gasket 6 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com