Variable arc metal U-shaped strip and assembly of glass dome

A variable, arc-shaped technology, applied in the field of U-shaped strips, can solve the problems of loose position of the splicing receiving port, falling off installation, unsightly, etc., and achieve the effect of ensuring the continuity of splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

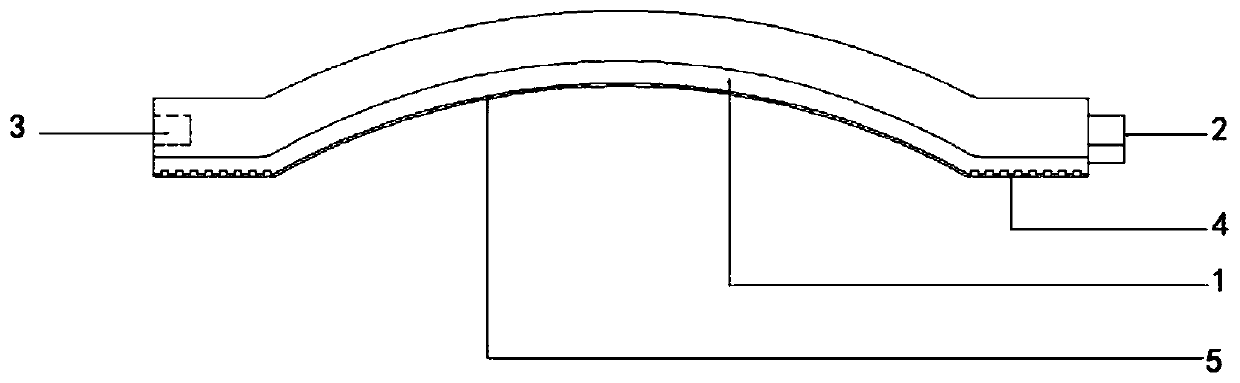

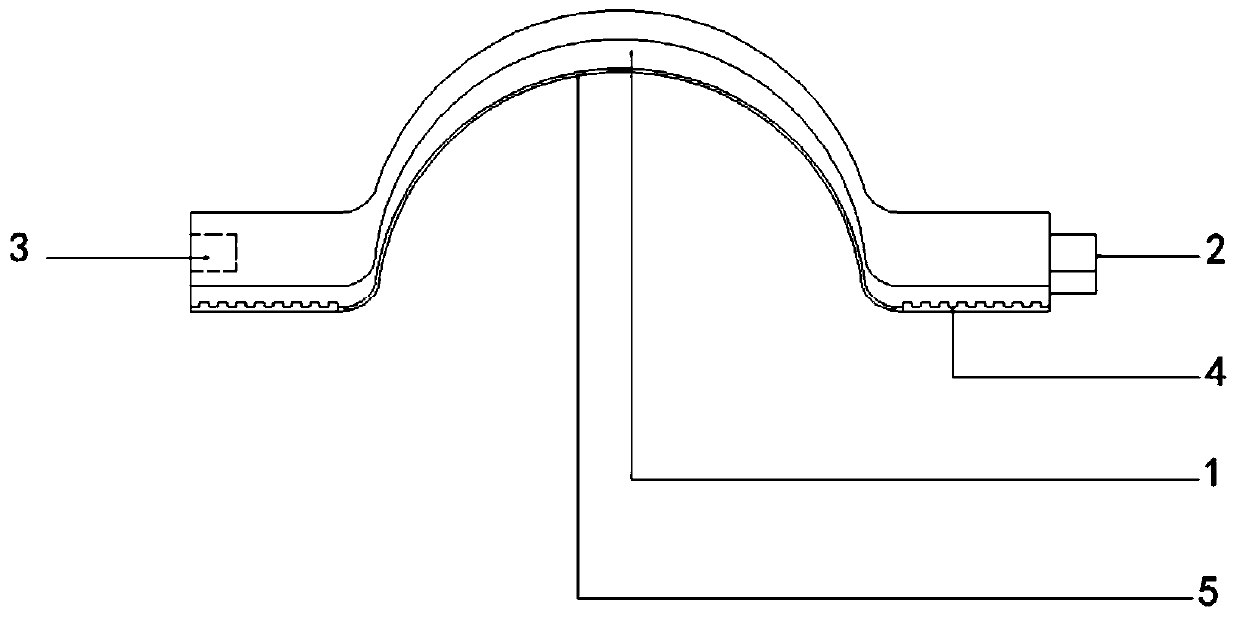

[0024] see figure 1 As shown, Embodiment 1 of the present invention discloses a variable arc metal U-shaped bar and assembly of a glass dome, which includes a variable arc metal U-shaped groove 1, an extension plug 2, an extension slot 3, an anti-skid Teeth 4 and environmental protection glue 5, wherein the extension plug 2 and the extension slot 3 are respectively located at both ends of the variable arc metal U-shaped groove 1, and the anti-slip teeth 4 are located under the variable arc metal U-shaped groove 1 At both ends of the surface, the environmental protection glue 5 is coated on the lower surface of the variable arc metal U-shaped groove 1 .

[0025] Specifically, the opening of the extension slot 3 is located on the upper surface of the variable arc-shaped metal U-shaped groove 1, and the variable arc-shaped metal U-shaped groove 1 is made of stainless steel to ensure the strength requirements of the overall connector. .

[0026] The variable arc metal U-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com