Fabricated dry-hang mounting structure for indoor large-scale water curtains

An installation structure and prefabricated technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of effect and difficulty of cleaning work, increase the concentrated load on the floor of the building, and the large amount of masonry works, so as to facilitate the surface layer quality, reduce concentrated load, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

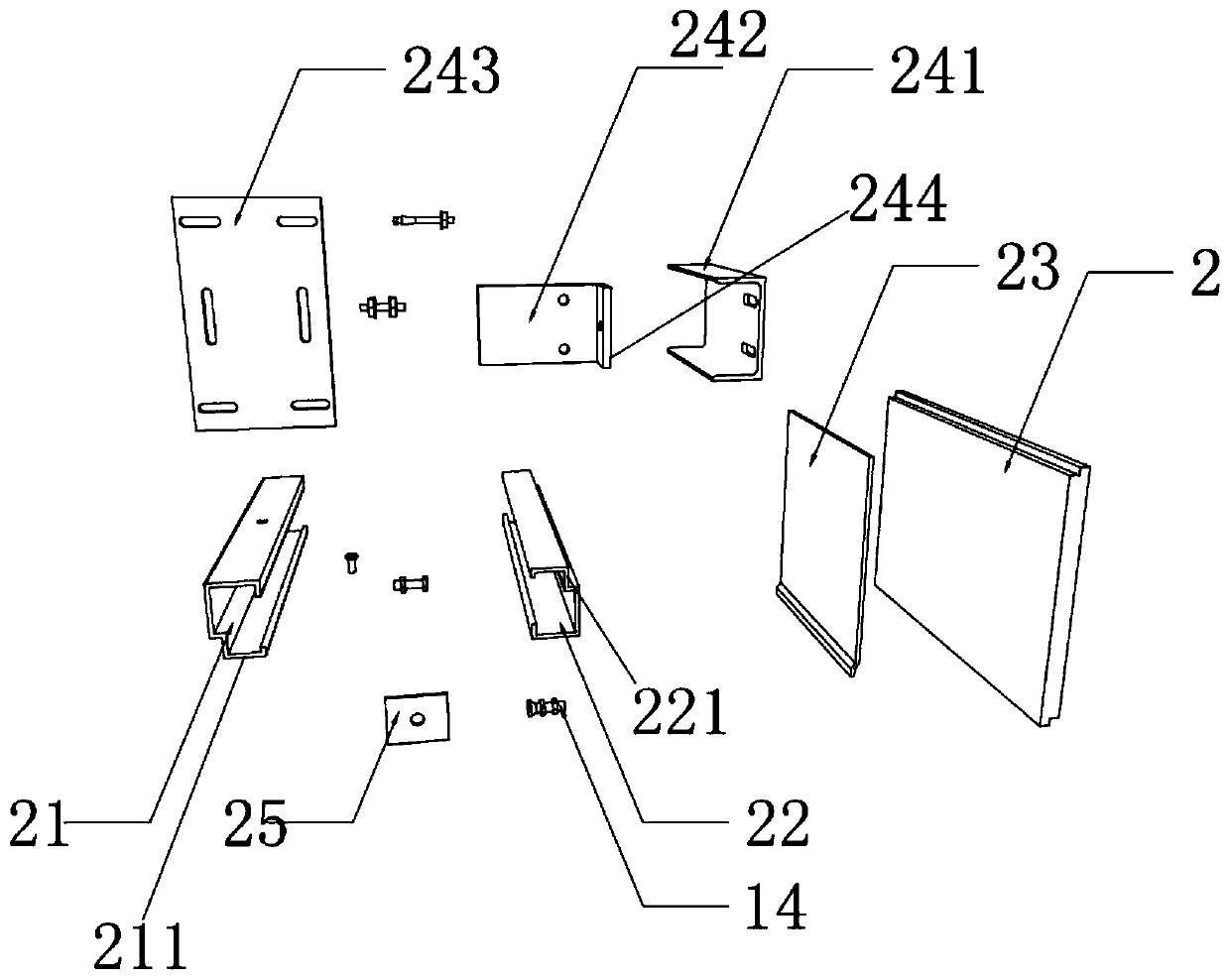

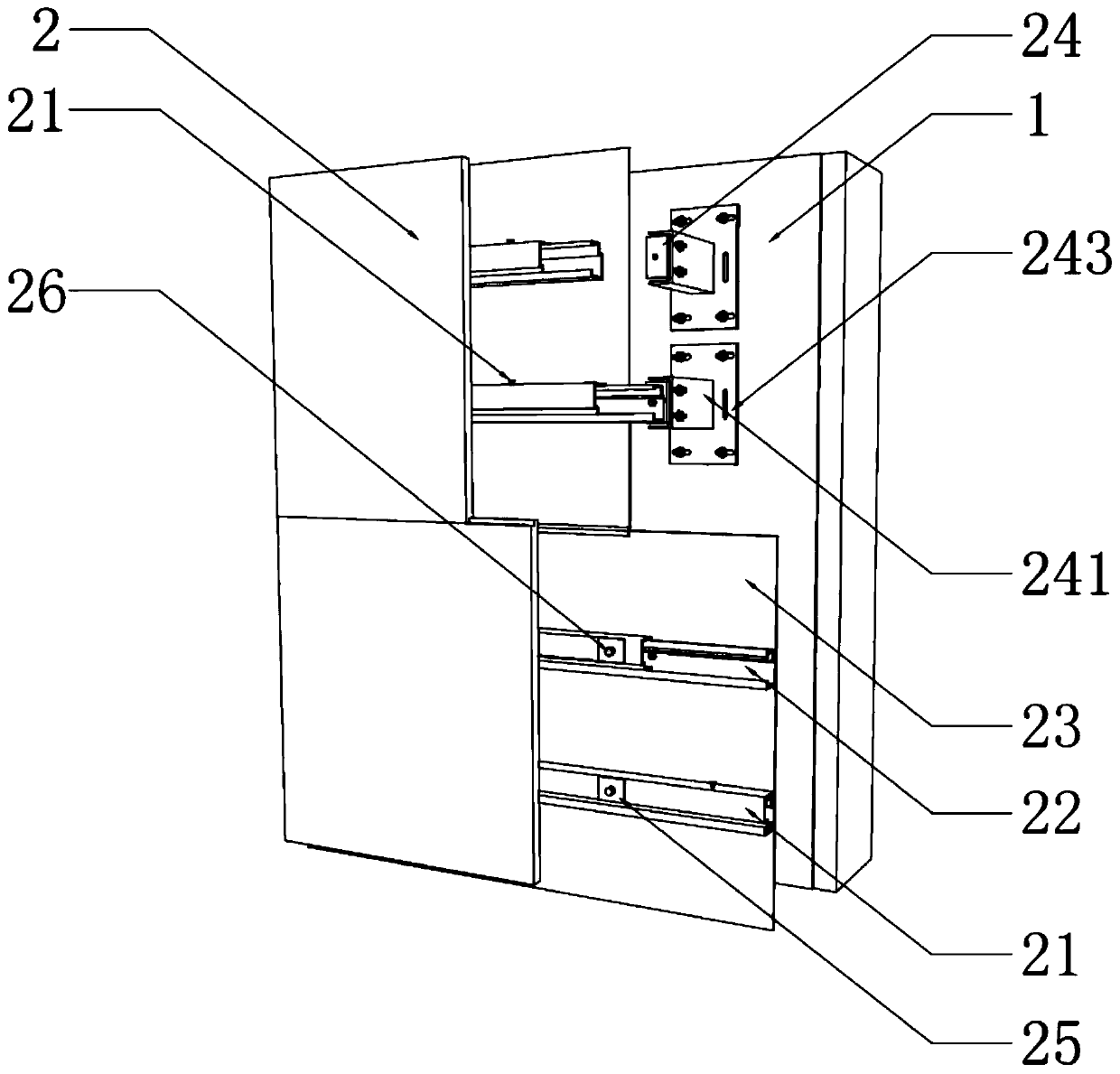

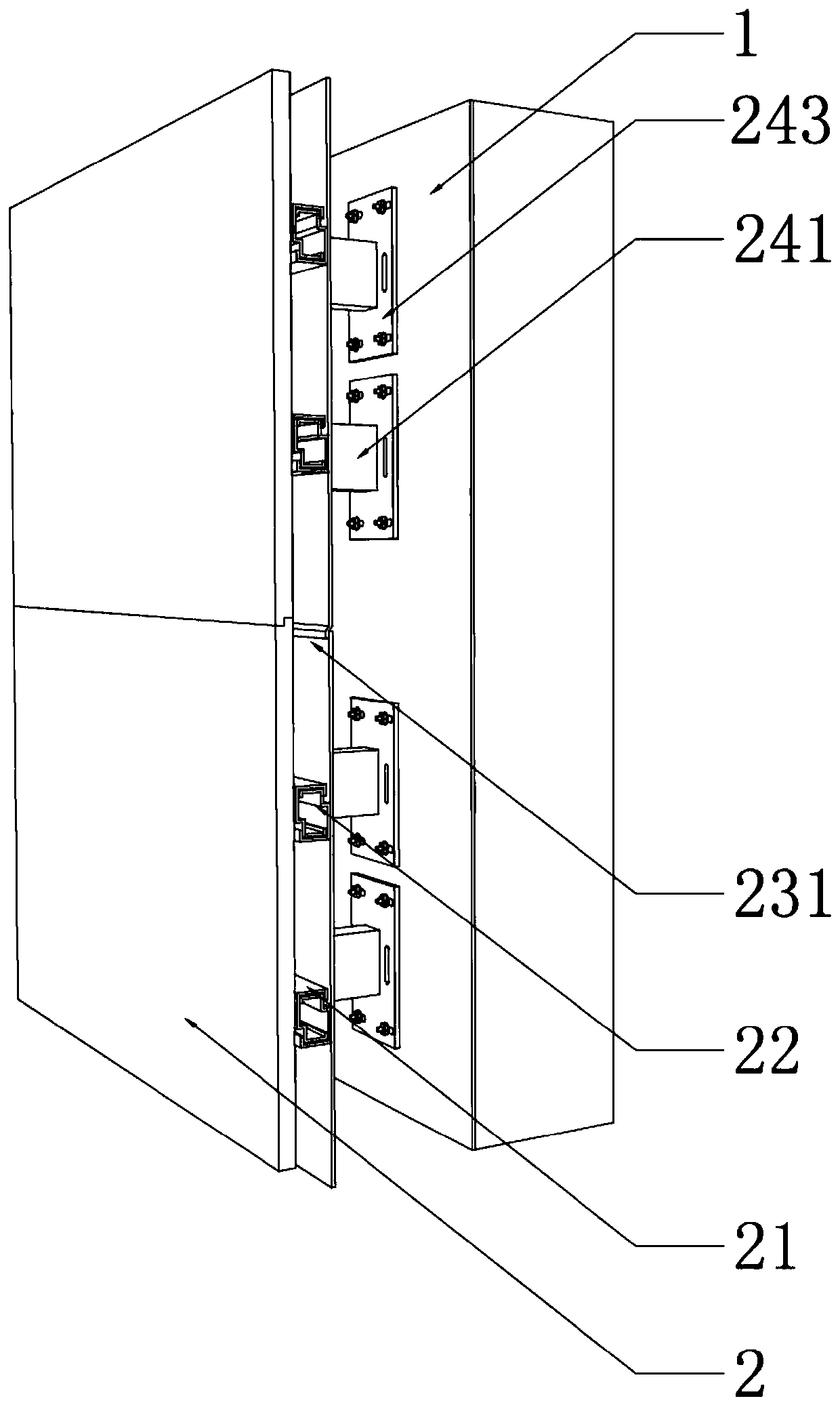

[0027] see Figure 1 to Figure 3 , the figure shows an indoor large-scale water curtain assembly type dry-hanging installation structure provided by Embodiment 1 of the present invention, which includes a base layer 1 on which a plurality of stone modules 2 are fixedly connected. The piece 21 is hooked on the second hooking piece 22 , the second hooking piece 22 is fixedly connected to the backing plate 23 , the backing plate 23 is fixedly connected to the adjusting part 24 , and the adjusting part 24 is fixedly connected to the base layer 1 .

[0028] see Figure 1 to Figure 3 , specifically, the cross-section of the first hook 21 is C-shaped, the cross-section of the second hook 22 is C-shaped, the first hook 21 and the second hook 22 are connected to each other, and the first The bottom of the hook 21 has a first hanging plate 211 with an L-shaped cross-section, and the top of the second hook 22 has a second hanging plate 221 with an L-shaped cross-section. The bottom of t...

Embodiment 2

[0044] see Figure 1 to Figure 3 , the figure shows an indoor large-scale water curtain assembly type dry-hanging installation structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Several rubber gaskets 25 are arranged between the first hook 21 and the second hook 22 . Through the arrangement of the above structure, the reinforcing effect of the connection between the two hooks can be realized.

Embodiment 3

[0046] see Figure 1 to Figure 3 , the figure shows an indoor large-scale water curtain assembly type dry-hanging installation structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The edge of the backing plate 23 has a bayonet 231 for clamping the edge of the adjacent backing plate, and the bayonet 231 is a V-shaped bent plate on the edge of the backing plate 23 . Through the setting of the above structure, the overlapping effect between adjacent backing plates can be realized, the sealing performance of the overall wall surface installation can be ensured, and the waterproof performance can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com